Catalog

Material Insight: Motorcycle Seat Upholstery Material

B2B Product Guide: Motorcycle Seat Upholstery Material

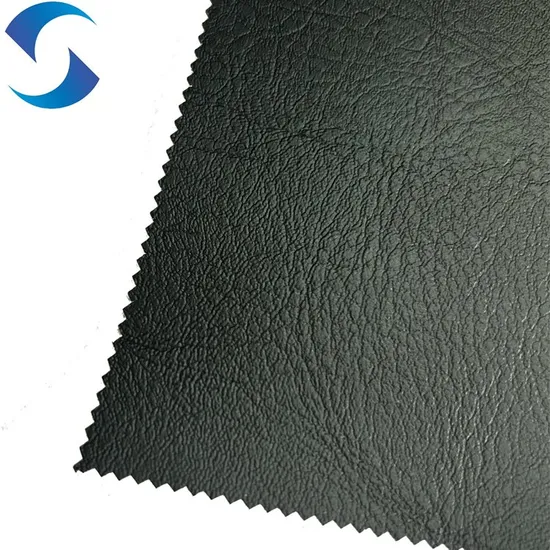

Selecting the optimal upholstery material for motorcycle seats is a critical engineering and design decision impacting rider safety, comfort, brand perception, and long-term product viability. Unlike automotive or furniture applications, motorcycle seats endure extreme, continuous stressors: intense UV exposure, rapid temperature fluctuations, persistent abrasion from rider movement, frequent moisture contact, and demanding chemical resistance requirements (oils, fuels, cleaning agents). Performance-driven materials must excel in durability, ergonomics, and environmental resilience without compromising aesthetic appeal.

Traditional genuine leather, while historically used, presents significant limitations for this high-stress application. Modern synthetic leather alternatives, specifically engineered for performance, now deliver superior functionality and sustainability. Here’s why specification-grade synthetic upholstery leather is the definitive choice:

- Unmatched Durability & Safety: Resists cracking, tearing, and abrasion far better than genuine leather under constant rider friction and vibration, maintaining structural integrity for safer, longer-lasting seats.

- Consistent Weather Resistance: Engineered polyurethane (PU) or polyester bases provide inherent resistance to UV degradation, water absorption, and temperature extremes (-30°C to +80°C), preventing swelling, hardening, or delamination.

- Enhanced Rider Comfort & Ergonomics: Precision-engineered thickness, flexibility, and breathability ensure optimal pressure distribution and reduced fatigue during extended rides, outperforming stiff or moisture-retaining genuine leather.

- Superior Chemical Resistance: Withstands exposure to oils, fuels, sweat, and common cleaning solvents without staining or degradation—critical for maintenance and rider hygiene.

- Sustainable Value Chain: Eliminates the environmental burden of chrome-tanned leather (high water/chemical use, toxic runoff) while offering traceable, consistent quality and reduced waste in cutting processes.

Introducing WINIW: Your Engineered Material Partner

WINIW has been a global leader in high-performance synthetic leather solutions for over 20 years, exclusively serving B2B industrial and transportation sectors. We specialize in developing specification-grade materials where reliability is non-negotiable. Our R&D-driven approach combines advanced polymer science with deep application expertise to create upholstery solutions that meet rigorous OEM standards for safety, longevity, and eco-compliance. Partnering with WINIW means accessing:

- Proprietary technologies for extreme abrasion resistance and weatherfastness

- Full customization of physical properties (thickness, tensile strength, colorfastness)

- Comprehensive eco-certifications (REACH, OEKO-TEX® STANDARD 100, GRS)

- Scalable production with ISO 9001-certified quality control

For motorcycle manufacturers demanding seats that perform flawlessly mile after mile while advancing sustainability goals, WINIW delivers engineered material excellence you can specify with confidence. Explore our dedicated motorcycle seat upholstery portfolio to elevate your next-generation designs.

Technical Performance & Standards

WINIW Motorcycle Seat Upholstery Material – Technical Product Guide

WINIW’s motorcycle seat upholstery material is engineered specifically for OEMs and Tier-1 suppliers seeking high-performance, durable, and compliant synthetic leather solutions. Designed to meet the rigorous demands of the motorcycle industry, this material combines advanced technical properties with environmental responsibility and manufacturing consistency.

The material is widely adopted in premium motorcycle seating applications due to its balanced performance in safety, comfort, and long-term durability. WINIW adheres to international quality standards and regulatory frameworks, ensuring seamless integration into global supply chains.

Key Technical Advantages

-

Fire Retardant Performance (UK & US Standards Compliant)

WINIW’s motorcycle seat material meets both UK and US flammability regulations, including BS 5852 (Source 0 & 1) and FMVSS 302. The proprietary formulation includes integrated flame-retardant additives that prevent rapid flame spread without compromising material flexibility or appearance. This ensures compliance with vehicle interior safety standards in major global markets. -

سهلة التنظيف والصيانة

The surface is treated with a stain-resistant topcoat that repels water, oils, and common contaminants. Cleaning requires only mild detergent and a damp cloth, making it ideal for high-use environments. The material retains its appearance after repeated cleaning cycles, reducing maintenance costs and extending product life. -

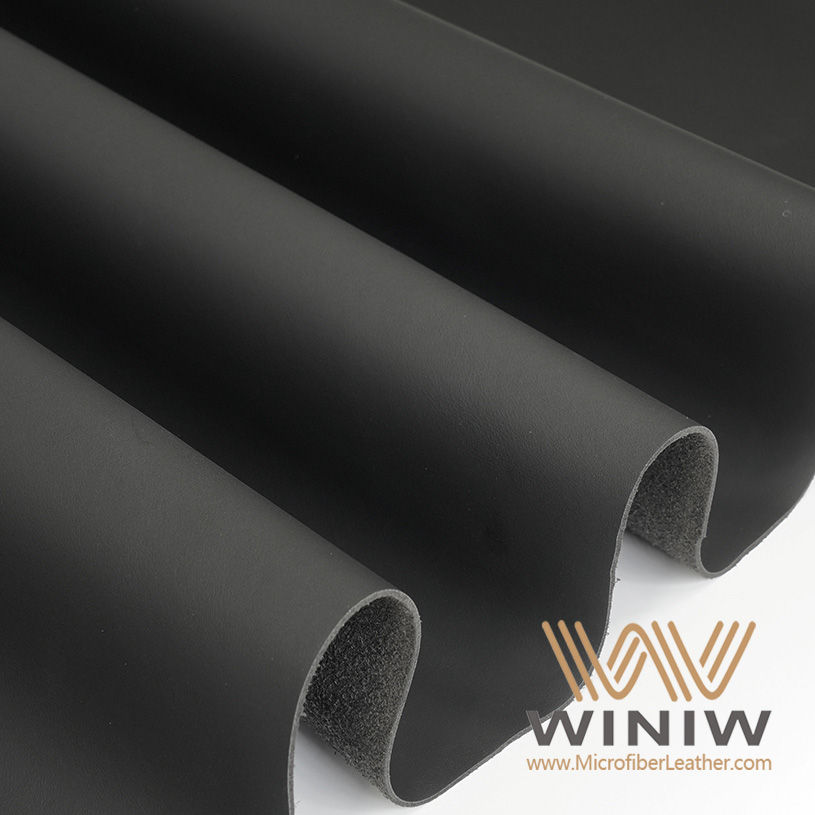

Superior Soft Touch and Comfort

WINIW’s micro-polyurethane coating and specially engineered backing deliver a leather-like hand feel with enhanced flexibility. The material conforms comfortably to ergonomic seat designs, reducing rider fatigue during prolonged use. Its consistent thickness and pliability support precision cutting and seamless upholstery wrapping. -

REACH Compliant Chemistry

All formulations are fully compliant with EU REACH regulations (EC 1907/2006), including SVHC (Substances of Very High Concern) restrictions. WINIW avoids the use of harmful phthalates, heavy metals, and carcinogenic dyes, ensuring safer handling for workers and end users. -

ISO 9001-Certified Manufacturing

Production is conducted in ISO 9001-certified facilities, guaranteeing consistent quality control, traceability, and process reliability. This ensures batch-to-batch uniformity, reduced defect rates, and reliable delivery timelines for B2B partners.

Technical Specifications

| Property | المواصفات |

|---|---|

| Base Material | High-tenacity polyester knit fabric |

| Coating Type | Micro-polyurethane (PU) |

| Thickness | 1.0 – 1.4 mm (customizable) |

| Weight | 380 – 420 g/m² |

| Tensile Strength (MD) | ≥ 90 N/5cm |

| Tear Strength (Elmendorf) | ≥ 15 N (warp & weft) |

| Color Fastness to Rubbing | Dry: ≥ 4, Wet: ≥ 3 (ISO 105-X12) |

| Light Fastness | ≥ 4 (ISO 105-B02, 20-hour exposure) |

| Fire Resistance | BS 5852 Source 0 & 1, FMVSS 302 compliant |

| REACH Compliance | Fully compliant (SVHC-free) |

| RoHS Compliance | Yes |

| Operating Temperature Range | -30°C to +80°C |

| Surface Finish | Matte, soft-touch, anti-scratch coating |

WINIW’s motorcycle seat upholstery material delivers a competitive edge through its integration of safety, durability, and sustainability. It is the preferred choice for manufacturers aiming to achieve high-end aesthetics without compromising on regulatory compliance or rider comfort.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Motorcycle Seat Upholstery Material Comparison

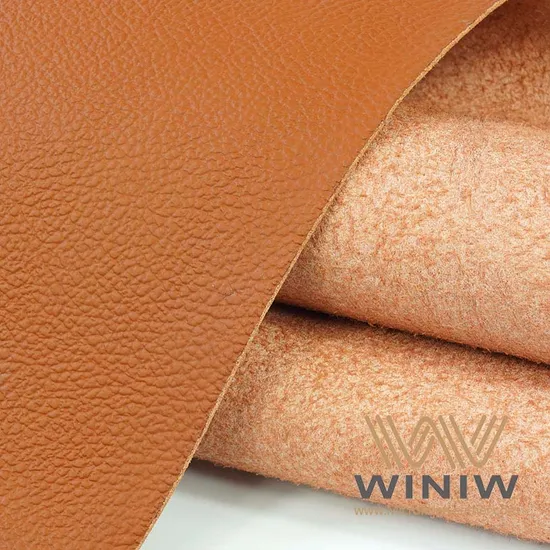

Selecting the optimal upholstery material for motorcycle seats requires balancing performance, sustainability, and total cost of ownership. WINIW® Synthetic Leather offers a high-performance, eco-conscious alternative to traditional real leather, engineered specifically for demanding transportation applications. Below is a technical comparison focused on critical B2B decision factors.

Key Comparison: WINIW Synthetic Leather vs. Real Leather

| Attribute | WINIW Synthetic Leather | Real Leather |

|---|---|---|

| Cost | 20-35% lower material cost. Consistent pricing, no grade fluctuations. Zero waste in cutting (100% usable yield). | Higher base cost (premium grades). Significant price volatility due to hide quality, origin, and tannery fees. 20-30% material waste due to natural defects. |

| المتانة | Superior UV resistance (5,000+ hrs ASTM G154). 3-5x higher abrasion resistance (Martindale >100,000 cycles). Waterproof, oil-resistant, and dimensionally stable in extreme temperatures (-30°C to 85°C). No cracking or hardening. | Moderate UV resistance (fades/cracks within 2-3 years exposure). Lower abrasion resistance (Martindale 20,000-40,000 cycles). Absorbs moisture/oils, leading to staining, warping, and microbial growth. Requires frequent conditioning. |

| Eco-Friendliness | 60-70% lower water usage in production. Zero toxic heavy metals (REACH/ OEKO-TEX® certified). 100% recyclable at end-of-life. Carbon footprint 45% lower than bovine leather (LCA verified). | High water consumption (15,000+ liters per kg). Chrome-tanning releases carcinogenic Cr(VI). Non-recyclable; landfill-bound. High carbon footprint from livestock + tanning (UN FAO data). |

Why WINIW Synthetic Leather Delivers Superior B2B Value

- Performance Reliability: Engineered for consistent thickness, tensile strength, and color fastness across batches – critical for OEM assembly line efficiency and warranty compliance.

- Supply Chain Resilience: No dependence on volatile hide markets or tannery lead times. Customizable color/texture in 2-3 weeks vs. 8-12+ weeks for exotic leathers.

- Regulatory Compliance: Meets global standards (EU REACH, US CPSIA) without hazardous substances. Supports ESG reporting with full lifecycle transparency.

- Total Cost Reduction: Eliminates conditioning/maintenance costs, reduces warranty claims from weather damage, and optimizes material yield.

WINIW Synthetic Leather provides motorcycle manufacturers with a future-proof material solution that outperforms real leather in technical performance, cost predictability, and environmental responsibility – without compromising on the premium aesthetic and tactile experience riders expect.

WINIW: Engineering Sustainable Performance Materials for the Mobility Industry.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong commitment to sustainability and quality, WINIW serves industries ranging from fashion and automotive to furniture and sports, delivering customized solutions that meet international standards.

The company operates from a state-of-the-art manufacturing facility spanning 100,000 square meters. This large-scale production base integrates advanced automation and environmentally responsible processes, enabling high-volume output without compromising on precision or sustainability. The facility is designed to support end-to-end production, from raw material processing to finished product finishing, ensuring full control over timelines and quality.

Key strengths of WINIW’s factory include:

- A dedicated R&D team of over 100 engineers and material scientists focused on developing cutting-edge synthetic leather technologies, including water-based, solvent-free, and recycled materials.

- Continuous investment in innovation to enhance product performance, durability, and environmental compliance.

- Strict quality control protocols implemented at every stage of production, including raw material inspection, in-line monitoring, and final product testing. WINIW adheres to ISO 9001 standards and conducts regular audits to maintain consistency and reliability.

- Compliance with international environmental and safety regulations, including REACH, ROHS, and OEKO-TEX® STANDARD 100.

WINIW’s products are exported to key markets worldwide, with a strong presence in Europe and the USA. The company partners with leading brands and manufacturers who demand high-quality, sustainable alternatives to genuine leather. Through scalable production capacity, technical expertise, and a global logistics network, WINIW ensures timely delivery and consistent product performance across all markets.

By combining manufacturing scale, technical innovation, and rigorous quality assurance, WINIW stands as a trusted B2B partner in the global synthetic leather industry.

Contact Us for Samples

WINIW Microfiber Leather: Premium Upholstery Solutions for Motorcycle Seats

WINIW delivers high-performance microfiber leather engineered specifically for demanding motorcycle seat applications. Our materials combine superior durability, rider comfort, and environmental responsibility—meeting the exacting standards of OEMs and aftermarket seat manufacturers. As a leader in sustainable synthetic leather innovation, we provide eco-conscious alternatives without compromising on strength, aesthetics, or safety.

Why WINIW Microfiber Leather for Motorcycle Seats?

- Extreme Durability: Resists abrasion, tearing, and punctures from daily use, exposure to elements, and rider movement.

- Enhanced Rider Safety: Optimized surface texture provides consistent grip in wet/dry conditions, reducing slippage.

- All-Weather Performance: UV-stable and waterproof (tested to 50,000+ light hours), preventing cracking, fading, or moisture damage.

- Eco-Engineered Composition: Made from 60%+ recycled polyester and plant-based polyurethane; free of heavy metals, phthalates, and DMF.

- Weight-Optimized: 30% lighter than traditional leather, contributing to overall vehicle efficiency without sacrificing structural integrity.

- Design Flexibility: Customizable thickness (1.2–2.0mm), textures (matte, embossed, perforated), and colors to match brand aesthetics.

Technical Specifications for Motorcycle Applications

| Property | WINIW Standard | Test Method | Industry Benchmark |

|---|---|---|---|

| Abrasion Resistance | 100,000+ cycles | ISO 5470 | 50,000 cycles |

| Tensile Strength | 35 MPa | ISO 1798 | 25 MPa |

| Colorfastness (UV) | Grade 5 | ISO 105-B02 | Grade 3–4 |

| Cold Crack Resistance | -30°C | ISO 1719 | -20°C |

| Recycled Content | 60–75% | GRSCertified | <20% (avg.) |

Sustainability Credentials

- Certifications: OEKO-TEX® STANDARD 100, REACH Compliant, ISO 14001.

- Lifecycle Impact: 45% lower carbon footprint vs. bovine leather; fully recyclable through WINIW’s take-back program.

- Water Conservation: Saves 17,000L water per kg vs. conventional leather tanning.

Partner with WINIW for Your Next Seat Project

Elevate your motorcycle seats with material engineered for performance, safety, and sustainability. WINIW supports B2B partners with:

– Rapid prototyping (7–10 day turnaround)

– Volume pricing for OEMs and tier-1 suppliers

– Technical documentation (DS, MSDS, LCA reports)

Request Free Samples & Technical Consultation

Contact our Motorcycle Division specialists to discuss custom formulations, compliance requirements, or order samples:

Email: MKT88@MicrofiberLeather.com

Quote reference: “MOTO-SEAT-2024” for expedited processing. Free samples available for qualified B2B partners.

WINIW: Where Performance Meets Planet Responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.