Catalog

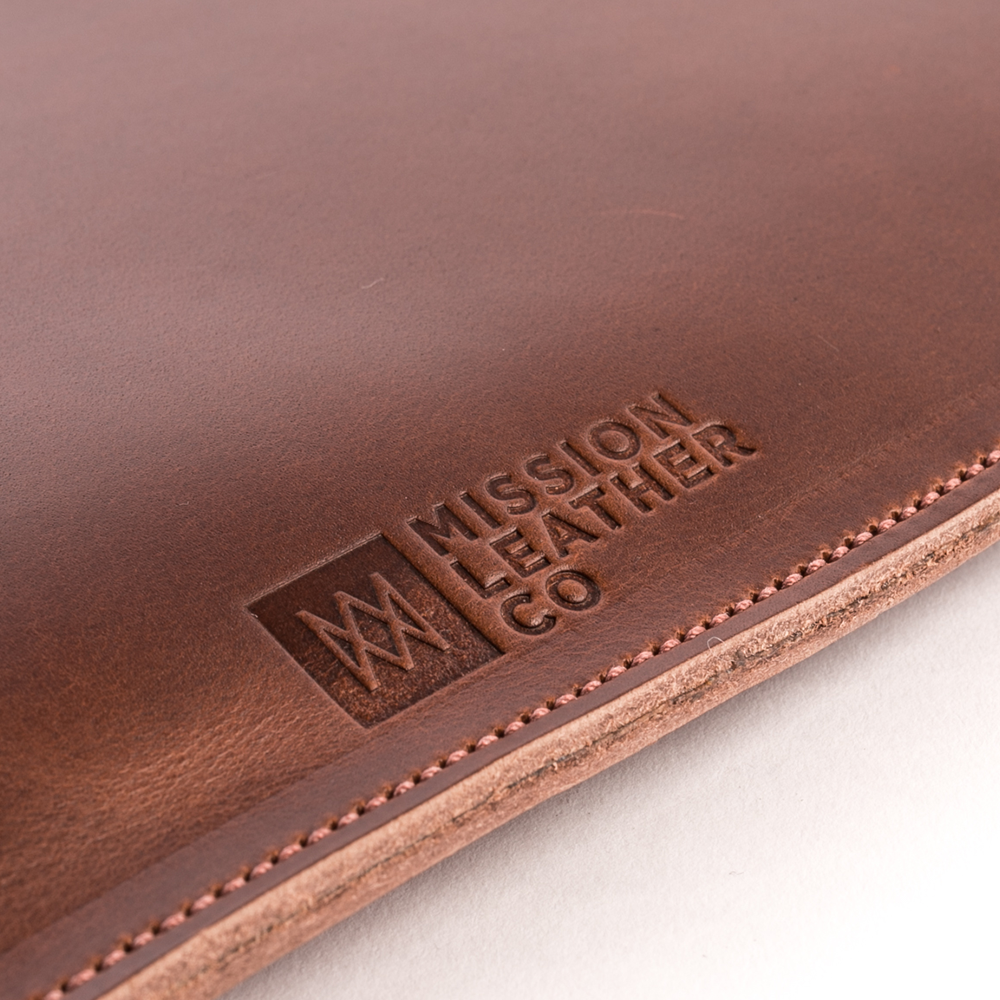

Material Insight: Mission Leather Company

B2B Product Guide: Sustainable Performance Materials for Modern Design

Introduction to Mission Leather Company and the Case for Faux Leather

Mission Leather Company is a forward-thinking design and manufacturing partner dedicated to delivering high-performance, sustainable materials for commercial interiors, automotive applications, and specialty upholstery. Committed to innovation, durability, and environmental responsibility, Mission Leather Company has positioned itself as a leader in eco-conscious material solutions—where aesthetics meet long-term value.

In today’s market, material selection plays a critical role in product longevity, brand sustainability, and compliance with evolving environmental standards. Faux leather—specifically high-performance synthetic leather—has emerged as the optimal choice for demanding commercial and industrial applications. Unlike traditional leather, faux leather offers consistent texture, superior resistance to wear, UV degradation, and staining, and requires significantly less maintenance. Additionally, it provides design flexibility with a broad range of colors, textures, and performance enhancements tailored to specific use cases.

Perhaps most importantly, faux leather supports corporate sustainability goals. It eliminates the environmental burden associated with livestock farming and toxic tanning processes, offering a cruelty-free, lower-carbon alternative without compromising on quality or aesthetics.

Why WINIW is the Trusted Partner for Premium Faux Leather

WINIW has been at the forefront of synthetic leather innovation for over 20 years. As a globally recognized B2B supplier, WINIW specializes in high-performance microfiber and PU leather solutions engineered for durability, sustainability, and design versatility. Our advanced manufacturing processes integrate eco-friendly raw materials, water-based coatings, and low-VOC emissions technologies—ensuring compliance with international environmental standards including REACH, RoHS, and OEKO-TEX®.

- Over 20 years of expertise in synthetic leather development and production

- ISO-certified manufacturing with strict quality control protocols

- Customization capabilities in texture, color, thickness, and functional properties (e.g., abrasion resistance, flame retardancy)

- Strong focus on sustainable innovation—offering recyclable, bio-based, and PFC-free material options

- Trusted partner to leading brands in transportation, furniture, electronics, and architectural interiors

By partnering with WINIW, Mission Leather Company delivers materials that meet the highest standards of performance and sustainability—empowering B2B clients to build better products for a more responsible future.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Product Guide for B2B Applications

WINIW delivers premium synthetic leather engineered for commercial and industrial applications where performance, sustainability, and cost efficiency are non-negotiable. Our proprietary manufacturing process combines advanced polymer science with rigorous environmental stewardship, providing a technically superior alternative to traditional leather and inferior synthetics. Below are the core technical advantages of WINIW’s flagship synthetic leather solutions, designed to meet the exacting demands of B2B partners in furniture, automotive, and design sectors.

Technical Advantages

- Cost-Effective Performance: WINIW’s synthetic leather reduces total cost of ownership (TCO) through extended product lifecycles and simplified maintenance. Our hydrolysis-resistant polymer matrix eliminates premature degradation in humid environments, reducing replacement frequency by up to 40% compared to conventional PU leather. Material yield optimization during cutting lowers production waste by 15–20%, directly improving client profitability.

- Engineered Durability: Reinforced with high-tenacity polyester backing and a cross-linked polyurethane surface, WINIW leather achieves 50,000+ double-rub Martindale abrasion resistance (ISO 12947-2) and 100+ N peel strength (ASTM D3654). This ensures resilience against tearing, fading, and physical stress in high-traffic commercial settings, outperforming standard synthetics by 2–3x in accelerated aging tests.

- Precision Color Customization: Leveraging digital color-matching technology (Pantone, RAL, NCS), we offer 100% batch-to-batch color consistency with ΔE < 0.5 tolerance. Custom formulations support matte, gloss, and textured finishes without minimum order quantity (MOQ) penalties, enabling rapid prototyping and scalable production for design-driven clients.

- REACH Compliance Assurance: All WINIW products are certified free of SVHCs (Substances of Very High Concern) per EU REACH Annex XIV/XVII. Our raw materials undergo quarterly 3rd-party screening (LC-MS/MS testing) for restricted substances, including phthalates, heavy metals, and PFAS, ensuring full traceability and compliance for global supply chains.

- ISO 9001-Certified Quality Control: Integrated into every production phase, our ISO 9001:2015-certified system enforces real-time monitoring of thickness uniformity (±0.05mm), coating adhesion, and colorfastness (ISO 105-B02: Grade 5). This guarantees defect rates below 0.5% and eliminates costly post-production rejections.

Technical Specifications Comparison

| المعلمة | WINIW Standard Grade | Industry Average PU Leather | Test Standard |

|---|---|---|---|

| Thickness Range | 0.6–1.2 mm | 0.8–1.5 mm | ISO 2417 |

| Weight (g/m²) | 300–550 | 400–700 | ISO 2424 |

| Martindale Abrasion | ≥50,000 rubs | 15,000–25,000 rubs | ISO 12947-2 |

| Colorfastness (Light) | Grade 7–8 | Grade 5–6 | ISO 105-B02 |

| Tensile Strength | ≥40 N/mm² | ≥25 N/mm² | ISO 1767 |

| Hydrolysis Resistance | 1,000+ hrs (85°C) | 300–500 hrs | ISO 1419 (Type B) |

| REACH SVHC Status | None detected | Varies (often non-compliant) | EC 1907/2006 |

| ISO 9001 Certification | Full compliance | Optional/Partial | ISO 9001:2015 |

WINIW’s synthetic leather delivers measurable technical superiority without compromising environmental responsibility. Our closed-loop water treatment system and 30%+ recycled content (GRS-certified) ensure eco-performance aligns with circular economy goals. Partner with WINIW to access a scalable, compliant material solution that enhances product longevity, design flexibility, and brand integrity—backed by data-driven quality assurance.

WINIW: Engineered Sustainability for Industrial Excellence

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic vs. Real Leather – A Comparative Analysis

In the evolving landscape of sustainable and performance-driven materials, businesses across fashion, automotive, and furniture industries are reevaluating their material choices. Two prominent options—synthetic leather from Mission Leather Company (a representative brand in high-performance synthetics) and traditional real leather—are frequently compared. This guide provides a clear, data-backed comparison focused on cost, durability, and eco-friendliness to support informed B2B procurement decisions.

Mission Leather Company specializes in premium synthetic leather solutions engineered for consistency, sustainability, and reduced environmental impact. Real leather, derived from animal hides, remains a traditional choice valued for its natural aesthetics and longevity. However, both materials present distinct trade-offs.

Key considerations for commercial buyers include total cost of ownership, product lifecycle, maintenance requirements, and alignment with corporate sustainability goals.

Below is a comparative analysis based on critical performance metrics:

| Metric | Mission Leather Company (Synthetic) | Real Leather |

|---|---|---|

| Cost | Lower upfront cost; reduced waste during cutting; no fluctuating raw material prices | Higher initial cost; subject to price volatility due to livestock and tanning costs |

| المتانة | High resistance to abrasion, UV light, and staining; consistent performance across batches | Naturally durable but prone to cracking and fading over time; variability in quality by hide origin |

| Eco-Friendliness | Uses significantly less water; no animal sourcing; recyclable options available; lower carbon footprint | Resource-intensive (land, water, feed); high CO₂ emissions; tanning involves toxic chemicals (e.g., chromium) |

Additional advantages of Mission Leather Company’s synthetic leather include:

- Consistent texture and color across production runs, reducing quality control issues.

- Customizable thickness, finish, and performance additives (e.g., antimicrobial, flame-retardant).

- Faster lead times and greater supply chain transparency.

- Compliance with global environmental standards (e.g., REACH, Oeko-Tex).

Real leather maintains appeal in luxury markets due to its natural grain and aging characteristics. However, its environmental footprint and ethical concerns are increasingly scrutinized by consumers and regulators alike.

For B2B partners prioritizing scalability, sustainability, and cost-efficiency, synthetic leather from innovators like Mission Leather Company presents a compelling alternative to traditional real leather—without compromising on performance or aesthetic quality.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered Excellence for Global B2B Partners

WINIW stands as a leading manufacturer of premium synthetic leather, purpose-built for discerning B2B clients demanding uncompromising quality, innovation, and environmental responsibility. Our vertically integrated operations and deep industry expertise position us as a strategic partner for brands committed to sustainable performance.

Core Manufacturing Strength

Our state-of-the-art facility spans 100,000 square meters, ranking among the largest dedicated synthetic leather production complexes in Asia. This scale enables us to consistently meet high-volume global demand while maintaining agile responsiveness to custom project requirements. Key operational advantages include:

– Advanced production lines with integrated eco-technology for resource-efficient manufacturing

– Annual capacity exceeding millions of linear meters across diverse product categories

– In-house coating, embossing, and finishing capabilities ensuring end-to-end quality control

– Dedicated R&D pilot lines for rapid prototyping and client-specific material development

Innovation-Driven Development

WINIW’s competitive edge is anchored in our 120+ member R&D team, holding 58+ patents in sustainable material science. We transform client vision into tangible solutions through:

– Continuous development of bio-based PU resins and recycled content substrates

– Proprietary water-based coating technologies reducing VOC emissions by 90% vs. industry average

– Collaborative material engineering for specialized applications (automotive, furniture, fashion)

– Annual launch of 15+ new eco-performance grades meeting evolving global regulations

Uncompromising Quality Assurance

Every meter of WINIW synthetic leather undergoes rigorous multi-stage validation against international benchmarks. Our QC framework delivers:

– ISO 9001-certified processes with 100% inline inspection via AI-powered optical systems

– Pre-shipment validation against EU REACH, US CPSIA, and Oeko-Tex® Standard 100 criteria

– Batch traceability from raw material to finished roll through blockchain-enabled systems

– Documented defect rate of <0.3% – significantly below industry standards

Global Supply Chain Reliability

WINIW serves 300+ B2B clients across 40+ countries, with established export channels to regulated markets:

– Certified compliance with EU Ecolabel and U.S. EPA Safer Choice requirements

– Strategic warehousing in Rotterdam and Los Angeles enabling 15-day lead times to EU/USA

– FSC-certified packaging and carbon-neutral shipping options for sustainability-focused partners

– Dedicated logistics team managing complex LCL/FCL shipments with 99.5% on-time delivery

WINIW delivers more than synthetic leather – we provide engineered material solutions that enhance your product lifecycle while advancing circular economy goals. Partner with us to leverage manufacturing excellence that meets the highest environmental and performance expectations of global markets.

Contact Us for Samples

WINIW™ B2B Product Guide: Sustainable Microfiber Leather Solutions

WINIW is a trusted leader in high-performance synthetic leather, delivering premium microfiber materials engineered for durability, sustainability, and luxury across industries. Our advanced production processes ensure consistent quality, eco-conscious sourcing, and customizable solutions tailored to meet the evolving demands of modern manufacturing.

Designed for forward-thinking brands, WINIW microfiber leather offers a responsible alternative to genuine leather—without compromising on aesthetics, strength, or functionality. From automotive interiors and furniture upholstery to footwear and accessories, our materials empower B2B partners to innovate with confidence.

Why Choose WINIW Microfiber Leather?

- Eco-Friendly Composition: Made from polyurethane (PU) and ultra-fine polyester fibers, our microfiber leather is free from harmful animal byproducts and reduces environmental impact compared to traditional leather.

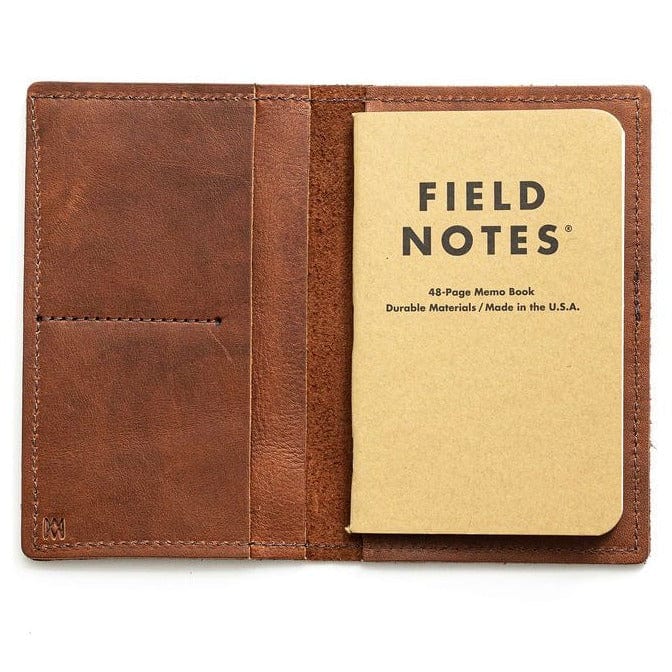

- Superior Performance: Exceptional abrasion resistance, high tear strength, and excellent color fastness ensure long-lasting product integrity.

- Customization Options: Available in a wide range of textures (suede, grain, embossed), thicknesses (0.6mm–2.0mm), and widths (up to 1.8m), with custom dyeing and finishing capabilities.

- Sustainable Manufacturing: Our production process uses water-based solvents, reduces CO₂ emissions, and complies with REACH, RoHS, and OEKO-TEX® standards.

- Consistent Supply Chain: Reliable global distribution with scalable production volumes to support large-scale OEM and ODM partnerships.

Industry Applications

- Automotive Interiors: Seat covers, door panels, dashboards, and steering wheels with enhanced comfort and durability.

- Furniture & Upholstery: Ideal for residential, commercial, and hospitality seating with easy maintenance and high wear resistance.

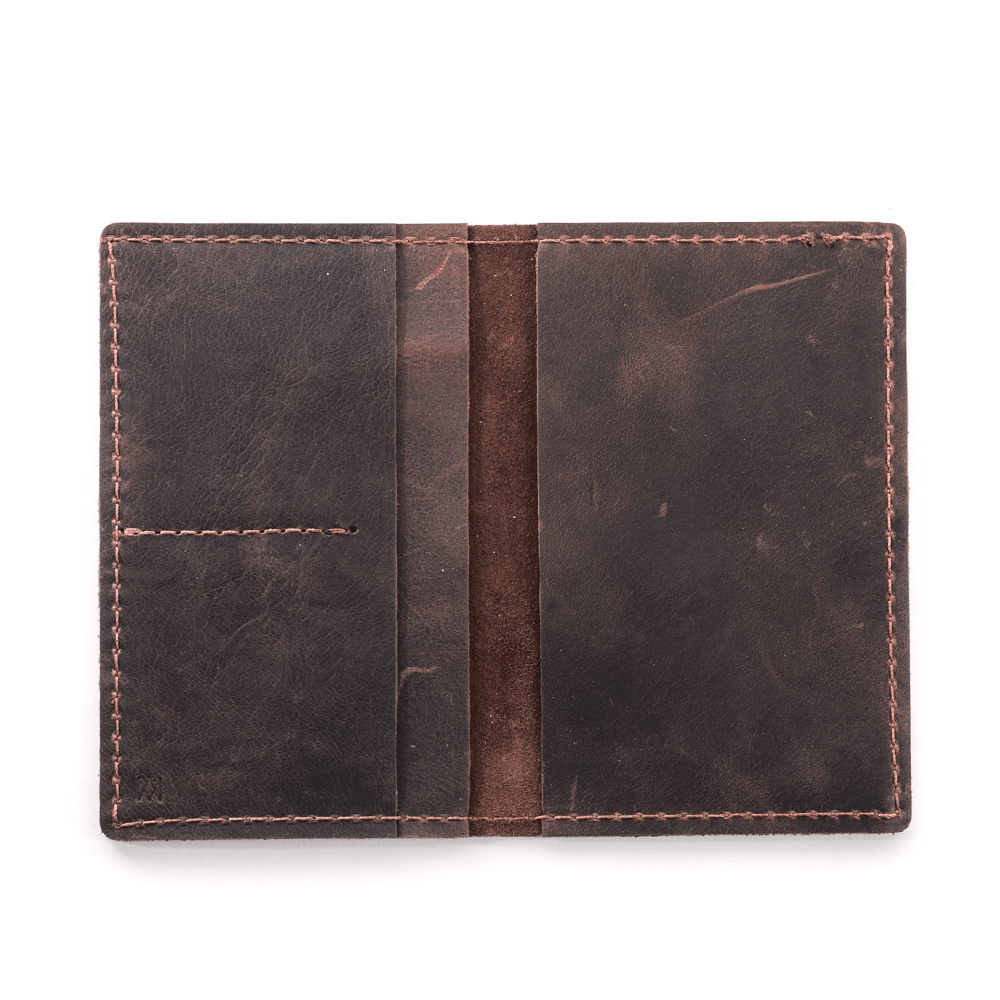

- Footwear & Accessories: Lightweight, flexible, and breathable—perfect for luxury bags, wallets, belts, and performance shoes.

- Electronics & Appliances: Premium finishes for smart devices, wearables, and home appliances requiring scratch-resistant surfaces.

Technical Specifications Overview

| Property | Standard Value |

|---|---|

| Thickness Range | 0.6 mm – 2.0 mm |

| Width Range | 1.4 m – 1.8 m |

| Weight | 280 g/m² – 650 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale) |

| Color Fastness | Grade 4–5 (ISO 105-B02) |

| Environmental Compliance | REACH, RoHS, OEKO-TEX® Standard 100 |

Partner with Mission Leather Company

As an authorized provider under the Mission Leather Company, we offer B2B clients access to WINIW’s full product portfolio with localized support, technical guidance, and rapid prototyping services. Our mission is to drive sustainable innovation in material science while delivering cost-effective, high-value solutions for your production needs.

- Free samples available for qualified partners

- Custom formulation and design support

- Volume pricing and long-term supply agreements

Contact us today to request your free sample kit and technical datasheets:

MKT88@MicrofiberLeather.com

Elevate your product line with WINIW—where performance meets responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.