Introduction: Navigating the Global Market for leather corset custom

In the ever-evolving landscape of fashion, sourcing custom leather corsets presents a unique challenge for international B2B buyers. With the demand for high-quality, stylish corsets increasing across markets in Africa, South America, the Middle East, and Europe, understanding how to navigate this specialized niche is essential. This guide is designed to empower you in making informed purchasing decisions by providing a comprehensive overview of the leather corset custom market.

From exploring various styles—such as overbust, underbust, and waspie corsets—to understanding the applications that span fashion-forward boutiques to niche costume retailers, this guide covers all aspects of sourcing. You will also find insights on supplier vetting processes, ensuring that you partner with manufacturers who prioritize craftsmanship and ethical practices. Furthermore, we will delve into pricing structures, allowing you to evaluate cost-effectiveness while maintaining quality.

By leveraging the information contained within this guide, B2B buyers can confidently approach suppliers, negotiate better terms, and ultimately enhance their product offerings. Whether you are in Germany, Brazil, or any other region, understanding the intricacies of custom leather corsets will set your business apart in a competitive market.

Table Of Contents

- Top 1 Leather Corset Custom Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather corset custom

- Understanding leather corset custom Types and Variations

- Key Industrial Applications of leather corset custom

- 3 Common User Pain Points for ‘leather corset custom’ & Their Solutions

- Strategic Material Selection Guide for leather corset custom

- In-depth Look: Manufacturing Processes and Quality Assurance for leather corset custom

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather corset custom’

- Comprehensive Cost and Pricing Analysis for leather corset custom Sourcing

- Alternatives Analysis: Comparing leather corset custom With Other Solutions

- Essential Technical Properties and Trade Terminology for leather corset custom

- Navigating Market Dynamics and Sourcing Trends in the leather corset custom Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather corset custom

- Strategic Sourcing Conclusion and Outlook for leather corset custom

- Important Disclaimer & Terms of Use

Understanding leather corset custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Overbust Corsets | Covers the bust, providing support and shaping | Fashion retail, costume design | Pros: Excellent bust support; versatile styling. Cons: May limit movement; sizing can be complex. |

| Underbust Corsets | Sits below the bust, accentuating the waist | Corsetry boutiques, theatrical costumes | Pros: Greater mobility; can be layered. Cons: Less bust support; may require additional garments for coverage. |

| Waspie Corsets | Shorter design, emphasizing the waistline | Fashion shows, alternative fashion | Pros: Trendy and stylish; ideal for layering. Cons: Limited torso coverage; may not suit all body types. |

| Longline Corsets | Extended length providing additional coverage and shaping | Bridal wear, formal attire | Pros: Smooths silhouette; good for formal wear. Cons: Can be restrictive; may require specific fitting. |

| Customizable Corsets | Tailored to individual measurements and preferences | High-end fashion, bespoke tailoring | Pros: Perfect fit; unique designs. Cons: Higher cost; longer production time. |

What Are the Characteristics of Overbust Corsets?

Overbust corsets are designed to cover the bust area, providing support while shaping the waist and enhancing the overall silhouette. They are particularly popular in fashion retail and costume design due to their versatility in styling. B2B buyers should consider the fabric quality, as premium leather can significantly affect durability and comfort. Additionally, sizing can be complex, requiring precise measurements to ensure customer satisfaction.

Why Choose Underbust Corsets for Your Business?

Underbust corsets sit below the bust, offering a unique silhouette that emphasizes the waist. They are favored in corsetry boutiques and theatrical costumes for their layering capability and greater mobility. Buyers should evaluate the design’s compatibility with other garments, as underbust styles often require additional clothing for coverage. The ability to customize these corsets can also be a selling point, appealing to clients looking for tailored solutions.

How Do Waspie Corsets Stand Out in the Market?

Waspie corsets are characterized by their shorter length, which focuses on accentuating the waistline. This style is particularly trendy in alternative fashion and fashion shows. B2B buyers should be aware that while waspie corsets are stylish and ideal for layering, they may not provide the same level of torso coverage as longer styles. Understanding the target market’s preferences is crucial when considering inventory.

What Benefits Do Longline Corsets Offer?

Longline corsets extend beyond the waist, providing additional coverage and a smooth silhouette, making them ideal for bridal wear and formal attire. B2B buyers should consider the balance between style and comfort, as these corsets can be restrictive. Additionally, they often require specific fitting to ensure a flattering look, which can influence purchasing decisions.

Why Invest in Customizable Corsets?

Customizable corsets are tailored to individual measurements and preferences, making them a premium option in high-end fashion and bespoke tailoring. These corsets allow for unique designs that cater to specific client needs. However, buyers should weigh the higher costs and longer production times against the potential for increased customer satisfaction and loyalty. Understanding market demand for customization can inform purchasing strategies effectively.

Key Industrial Applications of leather corset custom

| Industry/Sector | Specific Application of leather corset custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom high-fashion collections for runway shows | Enhances brand prestige and uniqueness in the market | Quality of leather, craftsmanship, and design flexibility |

| Costume & Theatrical Design | Specialty costumes for performances | Provides authenticity and visual impact in productions | Durability, comfort for wearers, and custom design options |

| Kink & Fetish Wear | Tailored corsets for niche markets | Targets a dedicated customer base, increasing sales potential | Material choices, customization options, and sizing accuracy |

| Historical Reenactment | Authentic period costumes | Appeals to enthusiasts and collectors, enhancing brand loyalty | Historical accuracy, craftsmanship, and material sourcing |

| Bridal & Formal Wear | Custom bridal corsets for weddings | Adds a unique touch to bridal attire, enhancing customer satisfaction | Design options, comfort, and fitting precision |

How is Leather Corset Custom Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, custom leather corsets are integral to high-fashion collections, particularly for runway shows and exclusive events. Designers leverage these corsets to create unique silhouettes that captivate audiences. The use of premium leather not only enhances the aesthetic appeal but also elevates the brand’s prestige. For international buyers, sourcing from reputable manufacturers who offer craftsmanship and design flexibility is crucial to ensure product quality and brand alignment.

What Role Do Leather Corsets Play in Costume & Theatrical Design?

In the realm of costume and theatrical design, custom leather corsets serve as essential components for creating authentic character portrayals. These corsets enhance the visual impact of performances, making them critical for theatrical productions, film, and themed events. Buyers in this sector must prioritize durability and comfort, as performers require garments that withstand extensive wear. Custom design options that allow for specific character adaptations are also vital for meeting the demands of diverse productions.

How Are Leather Corsets Utilized in the Kink & Fetish Wear Market?

The kink and fetish wear industry thrives on the uniqueness and boldness of custom leather corsets. Tailored to fit specific body types and preferences, these corsets cater to a niche market that values both aesthetics and functionality. Businesses can capitalize on this dedicated customer base by offering a range of customization options. Key sourcing considerations include the selection of high-quality materials and the accuracy of sizing to ensure customer satisfaction and repeat business.

Why Are Leather Corsets Important for Historical Reenactment?

Custom leather corsets play a significant role in historical reenactment, where authenticity is paramount. These garments help enthusiasts recreate specific time periods with accuracy, appealing to collectors and history buffs. Buyers in this sector must focus on historical accuracy, ensuring that the designs reflect the period’s styles. Craftsmanship and sourcing materials that match historical specifications are critical for maintaining authenticity and customer loyalty.

What Are the Benefits of Custom Leather Corsets in Bridal & Formal Wear?

In the bridal and formal wear industry, custom leather corsets offer a unique and personalized touch to wedding attire. These corsets can enhance the overall silhouette of bridal gowns, providing both style and support. For businesses, this customization can lead to increased customer satisfaction and referrals. When sourcing for this application, considerations such as design options, comfort, and precise fitting are essential to ensure a positive experience for brides.

3 Common User Pain Points for ‘leather corset custom’ & Their Solutions

Scenario 1: Sizing and Fit Challenges in Custom Leather Corsets

The Problem: One of the most significant challenges B2B buyers face when sourcing custom leather corsets is ensuring the right fit and sizing for their target market. Custom products often rely heavily on precise measurements, and inaccuracies can lead to dissatisfaction among end customers. This is especially critical in regions with diverse body types and sizing standards, such as Africa and South America. Misfit corsets can result in high return rates, damage brand reputation, and affect inventory management.

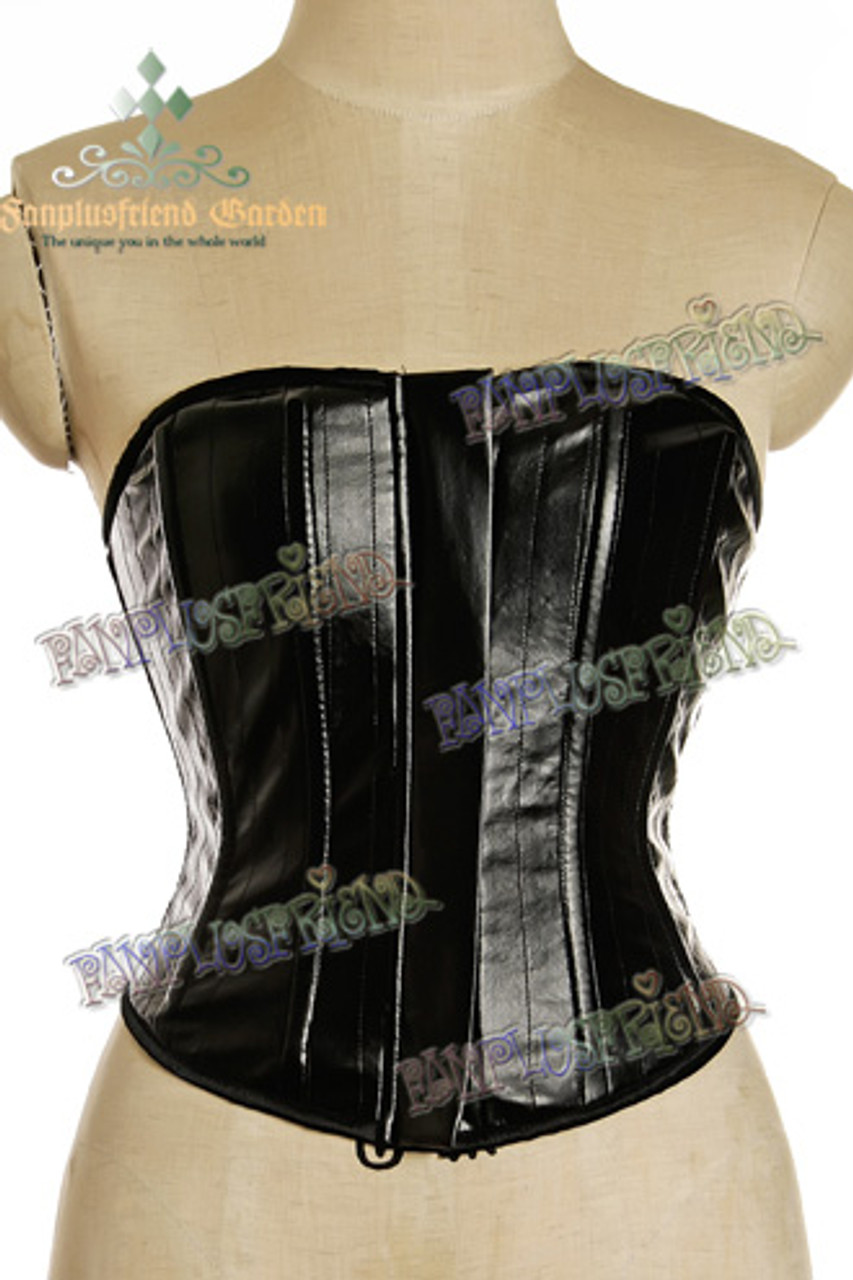

Illustrative image related to leather corset custom

The Solution: To overcome sizing challenges, it’s essential to adopt a comprehensive measurement strategy. First, collaborate closely with your manufacturer to develop a standardized size chart that accommodates the unique body types of your clientele. Encourage potential customers to provide detailed measurements, including bust, waist, and hip circumferences, as well as torso length. Implementing a virtual fitting tool or a detailed measurement guide on your e-commerce platform can also assist buyers in submitting accurate data. Additionally, consider offering a fitting sample program where you can send prototypes to key customers for feedback before full-scale production. This proactive approach will not only enhance customer satisfaction but also reduce return rates and improve overall sales.

Scenario 2: Material Quality and Durability Concerns

The Problem: B2B buyers often grapple with concerns regarding the quality and durability of leather used in custom corsets. Inconsistent material sourcing can lead to variations in texture, flexibility, and longevity, affecting customer satisfaction and trust. Buyers from regions like the Middle East, where the climate can be harsh, need assurance that the leather will withstand various conditions without deteriorating.

The Solution: To address these concerns, establish strong relationships with reputable suppliers who can guarantee high-quality leather. Conduct thorough research to verify the source of the leather, focusing on aspects such as tanning processes, ethical sourcing, and environmental impact. Request samples before placing large orders to assess the leather’s texture, thickness, and overall quality. It may also be beneficial to seek certifications or third-party assessments that validate the leather’s durability. Furthermore, communicate clearly with your clients about the care and maintenance of leather products, providing them with guidelines that emphasize proper cleaning and storage. This transparency not only builds trust but also empowers buyers to make informed decisions.

Illustrative image related to leather corset custom

Scenario 3: Design Limitations and Customization Options

The Problem: Another common pain point for B2B buyers is the perceived limitations in design options when ordering custom leather corsets. Buyers may have specific aesthetic requirements or unique branding needs that standard offerings do not meet. This is particularly relevant in markets like Europe, where fashion trends are diverse and rapidly evolving. Limited customization can hinder a buyer’s ability to differentiate their product line in a competitive market.

The Solution: To enhance design flexibility, engage with manufacturers who offer extensive customization options, including materials, colors, and embellishments. Initiate discussions about your specific design needs and explore the possibility of creating bespoke patterns or styles tailored to your brand identity. Utilize CAD (Computer-Aided Design) technology to visualize and prototype designs before production. Additionally, consider establishing a feedback loop with your customer base, allowing them to vote on design concepts or suggest features they would like to see. This collaborative approach not only fosters innovation but also ensures that the final product resonates with your target audience, thereby enhancing marketability and sales potential.

Strategic Material Selection Guide for leather corset custom

What Are the Key Materials Used in Custom Leather Corsets?

When selecting materials for custom leather corsets, it is essential to consider the various types of leather available, as each offers unique properties that can affect the performance, durability, and aesthetic of the final product. Below, we analyze four common types of leather used in corset manufacturing, providing insights that will aid international B2B buyers in making informed decisions.

How Does Full-Grain Leather Perform in Custom Corsets?

Full-grain leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. This type of leather is known for its exceptional durability and breathability, making it suitable for high-stress applications like corsets. It can withstand significant pressure without losing its shape, which is crucial for maintaining the corset’s structure over time.

Illustrative image related to leather corset custom

Pros: Full-grain leather offers superior durability and a luxurious appearance, making it ideal for high-end custom corsets. It ages beautifully, developing a unique patina that enhances its aesthetic appeal.

Cons: The cost of full-grain leather is relatively high, which may impact the overall pricing of the corset. Additionally, it requires more complex manufacturing processes, including specialized stitching techniques.

Impact on Application: Full-grain leather is highly compatible with various body types and can accommodate different styles, from gothic to steampunk.

Considerations for International Buyers: Buyers should ensure compliance with international leather sourcing standards, such as those set by the International Organization for Standardization (ISO). Full-grain leather is often preferred in European markets, particularly in Germany, where craftsmanship is highly valued.

What Advantages Does Top-Grain Leather Offer for Corsets?

Top-grain leather is the second-highest quality leather, made by sanding down the surface of full-grain leather to remove imperfections. This type of leather is slightly more flexible and easier to work with, making it a popular choice for custom corsets.

Illustrative image related to leather corset custom

Pros: Top-grain leather is more affordable than full-grain leather while still providing a good balance of durability and aesthetics. It is easier to dye and can be produced in various colors and finishes.

Cons: While it is durable, top-grain leather is not as robust as full-grain leather and may not age as gracefully. Over time, it can show signs of wear more quickly.

Impact on Application: Top-grain leather is suitable for corsets that require a softer feel while still providing support. It can be used effectively in both casual and formal designs.

Considerations for International Buyers: Buyers should be aware of regional preferences, as top-grain leather is often favored in markets where cost-effectiveness is a priority, such as South America.

How Does Suede Leather Compare for Corset Customization?

Suede leather, made from the underside of the hide, offers a unique texture that can add a distinct aesthetic to corsets. It is softer and more pliable than traditional leather, making it comfortable to wear.

Pros: Suede is lightweight and has a luxurious feel, making it ideal for fashion-forward designs. It can be easily dyed and is available in various colors.

Cons: Suede is less durable than full-grain and top-grain leather, making it less suitable for high-stress applications. It is also more susceptible to staining and requires special care.

Impact on Application: Suede can be used for fashion corsets that prioritize style over extreme durability, appealing to niche markets looking for unique designs.

Considerations for International Buyers: Buyers should consider the climate and care requirements for suede, particularly in humid regions like parts of Africa and the Middle East, where moisture can damage the material.

What Role Does Faux Leather Play in Custom Corset Manufacturing?

Faux leather, or synthetic leather, is an alternative to traditional leather that mimics its appearance while being more affordable and animal-friendly. It is often made from polyurethane (PU) or polyvinyl chloride (PVC).

Illustrative image related to leather corset custom

Pros: Faux leather is cost-effective, easy to maintain, and available in a wide range of colors and patterns. It is also more resistant to water and stains compared to genuine leather.

Cons: While it can look similar to real leather, faux leather lacks the breathability and durability of genuine leather. It may not provide the same level of support in corsetry.

Impact on Application: Faux leather is suitable for budget-friendly corsets and can attract a younger demographic interested in fashion without the ethical concerns associated with animal products.

Considerations for International Buyers: Buyers should ensure that the faux leather meets relevant compliance standards, such as those set by ASTM or DIN, particularly in European markets where environmental regulations are stringent.

Illustrative image related to leather corset custom

Summary Table of Material Selection for Leather Corsets

| Material | Typical Use Case for leather corset custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end custom corsets | Exceptional durability and luxury | High cost and complex manufacturing | High |

| Top-Grain Leather | Versatile custom corsets | Good balance of quality and cost | Less durable than full-grain | Medium |

| Suede Leather | Fashion-forward designs | Soft texture and lightweight | Less durable and prone to staining | Medium |

| Faux Leather | Budget-friendly and ethical options | Cost-effective and easy to maintain | Lacks durability and breathability | Low |

This strategic material selection guide provides a comprehensive overview of the various leathers used in custom corset production, enabling international B2B buyers to make informed decisions based on their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for leather corset custom

What Are the Key Stages in the Manufacturing Process of Custom Leather Corsets?

The manufacturing process for custom leather corsets involves several meticulous stages that ensure both quality and aesthetic appeal. Understanding these stages is crucial for B2B buyers who are looking to source high-quality products.

Material Preparation: How Is Leather Selected and Processed?

The first step in creating a leather corset is the careful selection of leather. Various types of leather, such as cowhide, lambskin, or suede, may be chosen based on desired durability and finish. This selection process often includes evaluating the leather’s grain, thickness, and flexibility.

Once the leather is selected, it undergoes preparation, which may involve conditioning and dyeing. Techniques such as vegetable tanning or chrome tanning can influence the leather’s final appearance and feel. For custom corsets, buyers should ensure that suppliers use high-quality, ethically sourced leather that meets international environmental standards.

Forming: What Techniques Are Used to Shape the Corset?

After preparing the leather, the next stage is forming. This typically involves cutting the leather into pre-defined patterns that correspond to the desired design of the corset. Advanced techniques such as laser cutting can be employed for precision, ensuring that each piece aligns perfectly during assembly.

At this stage, some manufacturers may also incorporate steel boning, which provides structure and support. The boning channels are meticulously measured and sewn into the fabric to accommodate the intended waist size and shape. This process is vital for achieving the distinctive hourglass silhouette that corsets are known for.

Assembly: How Are the Pieces Joined Together?

The assembly process involves stitching together the pre-cut leather pieces. High-quality threads that are resistant to wear and tear are used to ensure durability. Skilled artisans often employ techniques like double-stitching or using reinforced seams to enhance strength.

In addition to stitching, various fastening mechanisms such as laces, hooks, or zippers are integrated. Each fastening option should be tested for functionality and durability, as these components greatly affect the corset’s wearability.

Finishing: What Final Touches Are Added to the Corset?

The final stage in the manufacturing process is finishing, where the corset undergoes treatments that enhance its aesthetic appeal. This may include polishing the leather, adding decorative elements, or applying protective coatings to ensure longevity.

Quality assurance checks are essential during this stage to ensure that the final product meets the design specifications. This includes checking for uniformity in color, texture, and overall craftsmanship.

What Quality Assurance Measures Are Essential for Custom Leather Corsets?

Quality assurance (QA) is vital in ensuring that custom leather corsets meet both consumer expectations and regulatory standards. For B2B buyers, understanding the QA measures in place can significantly impact purchasing decisions.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers of leather corsets should adhere to various international quality standards. ISO 9001, which focuses on quality management systems, is a foundational standard applicable across industries. Additionally, certifications like CE marking can indicate compliance with European safety and health regulations.

For buyers in specific regions, being aware of local standards—such as Brazil’s ANVISA regulations or South Africa’s SANS standards—can also be beneficial. Understanding these standards can help buyers assess the credibility of potential suppliers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the manufacturing process. The main checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted at various stages to identify defects early on.

- Final Quality Control (FQC): This final inspection checks the completed corsets against design specifications and quality standards.

By understanding these checkpoints, B2B buyers can better gauge the reliability of their suppliers’ QC processes.

Illustrative image related to leather corset custom

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are employed to assess the quality of leather corsets. These include:

- Durability Tests: Assessing the strength of seams and the leather’s resistance to wear.

- Colorfastness Tests: Ensuring the leather does not bleed or fade when exposed to moisture.

- Fit and Comfort Assessments: Conducting wear tests to ensure that the corset is comfortable for extended use.

Buyers should inquire about these testing methods when evaluating potential suppliers to ensure that they deliver products that meet quality expectations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is critical. This can be accomplished through several methods:

What Steps Can Buyers Take to Audit Suppliers?

- Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes and quality assurance measures. These can be performed by the buyer or through third-party inspection services.

- Request Quality Reports: Suppliers should be able to provide documentation detailing their QC processes, including inspection results and compliance certifications.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the quality of the products being manufactured. This is particularly useful for buyers who may not have the capacity to conduct on-site audits.

What Are the Nuances of Quality Control for International Buyers?

Different regions may have varying expectations and standards regarding quality control. For instance, European buyers may prioritize CE marking, while buyers from Africa or South America might focus on local compliance standards. Understanding these nuances can help buyers make informed decisions and establish clear expectations with suppliers.

Illustrative image related to leather corset custom

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for custom leather corsets is essential for B2B buyers. By focusing on material selection, forming techniques, assembly methods, and rigorous quality control, buyers can ensure they source high-quality products that meet both their needs and international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather corset custom’

This guide serves as a practical checklist for B2B buyers interested in sourcing custom leather corsets. By following these steps, you can ensure a smooth procurement process while securing high-quality products that meet your specifications.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the type of leather, style (e.g., underbust, overbust, waist cincher), and any specific design features such as lacing, buckles, or embellishments. A well-defined specification helps suppliers understand your needs, reducing the risk of miscommunication.

- Material Quality: Specify if you prefer genuine leather, faux leather, or a mix.

- Sizing Requirements: Ensure you have accurate size charts to avoid fit issues.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom leather corsets. Look for manufacturers with a solid track record and positive reviews from previous clients. This step is crucial in ensuring product quality and reliability.

- Industry Experience: Check how long the supplier has been in the corsetry business.

- Client Portfolio: Review their previous work to assess quality and design capabilities.

Step 3: Request Samples

Once you have narrowed down your options, request samples of the leather and finished corsets. This step is vital for evaluating the quality of materials and craftsmanship before making bulk orders.

- Material Inspection: Examine the texture, durability, and overall finish of the leather.

- Fit Testing: If possible, test the samples for fit and comfort on your target demographic.

Step 4: Evaluate Supplier Certifications and Compliance

Verify that your potential suppliers comply with international quality standards and regulations. Certifications related to leather sourcing and production can indicate a commitment to quality and ethical practices.

- Sustainability Practices: Inquire about the sourcing of their leather and whether they adhere to environmentally friendly practices.

- Quality Certifications: Look for ISO certifications or other relevant industry standards.

Step 5: Negotiate Terms and Pricing

Initiate discussions around pricing, minimum order quantities, lead times, and payment terms. Effective negotiation can lead to better pricing and favorable terms, ensuring a profitable relationship.

Illustrative image related to leather corset custom

- Bulk Discounts: Ask about pricing structures for larger orders.

- Payment Flexibility: Discuss payment methods and timelines to align with your cash flow needs.

Step 6: Establish Clear Communication Channels

Set up clear lines of communication with your chosen supplier to facilitate an efficient workflow. Regular updates and feedback can prevent misunderstandings and delays during production.

- Point of Contact: Identify a dedicated representative from the supplier’s team for queries.

- Communication Tools: Agree on preferred methods (e.g., email, project management tools) for updates and discussions.

Step 7: Monitor Production and Quality Control

Once production begins, maintain oversight to ensure that the products meet your specifications. Regular check-ins and quality control measures can help identify issues early in the process.

- Production Timeline: Establish milestones for delivery and inspect samples at each stage.

- Final Quality Check: Conduct a final inspection of the completed corsets before accepting the shipment.

By following this checklist, B2B buyers can streamline the sourcing process for custom leather corsets, ensuring they receive high-quality products that meet their business needs.

Illustrative image related to leather corset custom

Comprehensive Cost and Pricing Analysis for leather corset custom Sourcing

Understanding the cost structure and pricing dynamics for custom leather corset sourcing is crucial for B2B buyers, especially those operating in diverse international markets. The following analysis breaks down the key cost components, price influencers, and provides actionable tips for buyers.

What Are the Key Cost Components in Custom Leather Corset Production?

-

Materials: The primary cost driver in leather corsets is the quality of leather used. Full-grain leather, which is more durable and luxurious, commands a higher price compared to lower-grade options. Additional materials, such as laces, buckles, and linings, also contribute to overall costs.

-

Labor: Skilled labor is essential in corset manufacturing, as the production process requires precision and craftsmanship. Labor costs can vary significantly based on the region, with countries known for high-quality craftsmanship often having higher wage rates.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and other operational expenses. Overhead can fluctuate based on the manufacturing location, which may be a consideration for international buyers.

-

Tooling: Custom designs often necessitate specialized tools and molds, which can add to the initial investment. The cost of tooling is particularly relevant for unique designs or small production runs.

-

Quality Control (QC): Ensuring that each corset meets quality standards incurs additional costs. QC processes can be more rigorous for higher-end products, impacting overall pricing.

-

Logistics: Shipping costs can vary widely depending on the destination and the terms of shipping. International buyers should factor in customs duties, tariffs, and potential delays.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. Margins can differ based on supplier reputation, product exclusivity, and market demand.

How Do Price Influencers Affect the Cost of Leather Corsets?

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to achieve better pricing.

-

Specifications and Customization: The more specific the buyer’s requirements—such as unique designs, sizes, or materials—the higher the potential costs. Suppliers may charge extra for bespoke modifications.

-

Quality and Certifications: Higher-quality materials and certifications (e.g., ethical sourcing, sustainability) can increase costs but may also appeal to specific market segments that prioritize these attributes.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can significantly influence pricing. Established suppliers with a proven track record may charge a premium.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers in terms of shipping costs, risks, and logistics, which can impact overall pricing.

What Are Effective Buyer Tips for Negotiating Leather Corset Prices?

-

Negotiate Wisely: Leverage volume commitments and long-term partnerships to negotiate better pricing. Highlighting potential for future orders can incentivize suppliers to offer discounts.

-

Focus on Total Cost of Ownership: Assess not just the initial purchase price but also the long-term costs associated with durability, maintenance, and potential resale value. A higher upfront cost may lead to lower overall expenses.

-

Understand Pricing Nuances for International Transactions: Be aware of fluctuations in currency exchange rates, customs duties, and shipping costs that can affect final pricing. It’s beneficial to have a clear understanding of the total landed cost.

-

Research Supplier Backgrounds: Investigate potential suppliers’ reputations and customer feedback. A supplier with a strong track record of quality and reliability may justify a higher price point.

-

Stay Informed About Market Trends: Keeping abreast of market trends and shifts in consumer preferences can help buyers make informed decisions about when to purchase and at what price.

Conclusion

Navigating the complexities of custom leather corset sourcing requires a thorough understanding of the cost structure and the factors influencing pricing. By leveraging this knowledge, B2B buyers can make more informed decisions, negotiate better deals, and ultimately enhance their purchasing strategies in the competitive global market.

Disclaimer: Prices mentioned are indicative and may vary based on supplier, specifications, and market conditions.

Alternatives Analysis: Comparing leather corset custom With Other Solutions

Exploring Alternatives to Leather Corset Custom Solutions

When considering the procurement of leather corsets, particularly for B2B applications, it’s essential to evaluate various alternatives that can meet similar needs. This analysis will compare the custom leather corset option against other viable solutions, helping buyers identify the best fit for their specific requirements.

Illustrative image related to leather corset custom

| Comparison Aspect | Leather Corset Custom | Alternative 1: Fabric Corsets | Alternative 2: Steel-Boned Corsets |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Moderate durability, versatile styling | Excellent support and waist reduction |

| Cost | Premium pricing ($1,445 – $4,295) | Generally lower cost ($100 – $500) | Mid-range pricing ($200 – $800) |

| Ease of Implementation | Longer lead time due to customization | Quick availability for ready-made options | May require fitting adjustments |

| Maintenance | Requires specialized care for leather | Easy to clean and maintain | Moderate maintenance; some may require special care |

| Best Use Case | High-end fashion, cosplay, and theatrical | Everyday wear, casual events | Tight-lacing, historical reenactments |

What Are the Benefits and Drawbacks of Fabric Corsets?

Fabric corsets present a versatile alternative to leather options. They are typically more affordable, making them accessible for a wider range of customers. Additionally, fabric corsets come in various styles, colors, and patterns, allowing for greater customization in terms of aesthetics. However, they may not provide the same level of durability or support as leather corsets, which can affect their performance in specialized applications like waist training or theatrical performances.

Why Consider Steel-Boned Corsets as an Alternative?

Steel-boned corsets are renowned for their structural integrity and ability to shape the body effectively. They are often used for tight-lacing and can provide significant waist reduction. While their price point is higher than fabric corsets, it is generally lower than custom leather options. However, they may require fitting adjustments to ensure comfort and effectiveness, which could lead to longer lead times compared to readily available fabric options.

How to Choose the Right Solution for Your Needs

When deciding between custom leather corsets and alternative solutions, B2B buyers should consider several factors, including the intended use, budget constraints, and maintenance capabilities. If the goal is to create a high-end product for theatrical or fashion purposes, a custom leather corset may be the best option despite its higher cost and maintenance needs. Conversely, for casual wear or bulk purchases, fabric or steel-boned corsets may provide a more economical and versatile solution. Ultimately, evaluating the specific requirements of your target market will guide you in selecting the most appropriate corset solution.

Essential Technical Properties and Trade Terminology for leather corset custom

What Are the Key Technical Properties of Custom Leather Corsets?

When engaging in the B2B market for custom leather corsets, understanding specific technical properties is essential for ensuring quality and meeting customer expectations. Here are some critical specifications to consider:

Illustrative image related to leather corset custom

-

Material Grade

– The quality of leather used in corset manufacturing is paramount. Full-grain leather is the highest quality, providing durability and a luxurious finish. Choosing the right grade impacts not only the aesthetic appeal but also the longevity and performance of the corset, influencing customer satisfaction and return rates. -

Steel Boning

– Corsets typically feature steel boning to provide structure and support. The gauge of the steel (commonly 16-20 gauge) determines the corset’s strength and flexibility. Understanding the specifications of the boning allows manufacturers to cater to different styles and purposes, such as fashion versus waist training. -

Tolerance Levels

– Tolerance refers to the allowable variation in measurements during production. For custom corsets, maintaining tight tolerances (often within ±1 cm) ensures a proper fit, which is crucial for comfort and effectiveness. High tolerance levels reduce returns and enhance customer satisfaction, making it a vital consideration for B2B transactions. -

Closure Type

– The type of closure (e.g., busk, lace-up, zipper) affects both the functionality and ease of use. Each closure type has different implications for wearability and style. Understanding the benefits and limitations of various closures helps suppliers recommend the best options for specific customer needs. -

Finish and Treatment

– Leather can undergo various treatments to enhance durability and appearance, such as waterproofing or dyeing. The chosen finish affects the product’s marketability, particularly in diverse climates and fashion trends. B2B buyers should consider treatment specifications to ensure they align with target market preferences. -

Sizing Options

– Offering a range of sizing options, including custom measurements, is crucial in the corset market. This flexibility meets the diverse needs of consumers, particularly in regions with varying body shapes and sizes. Understanding sizing specifications helps manufacturers manage production efficiently and cater to specific demographic requirements.

What Are Common Trade Terms Related to Custom Leather Corsets?

Familiarity with industry jargon is essential for effective communication in the B2B leather corset market. Here are some commonly used trade terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that produces parts or products that are used in another company’s end product. In the leather corset industry, an OEM might manufacture the corset while another brand markets it. Understanding OEM relationships is vital for sourcing and partnership strategies. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For custom leather corsets, MOQs can vary significantly based on the manufacturer and the complexity of the designs. Knowing the MOQ helps buyers plan their inventory and budget effectively. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for a specific order. This process is crucial for B2B buyers to compare offers and negotiate better terms. A well-prepared RFQ can lead to more favorable pricing and delivery terms. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international shipping. They clarify aspects such as who pays for shipping, insurance, and duties. Familiarity with Incoterms is essential for B2B transactions, especially when dealing with international partners in Africa, South America, the Middle East, and Europe. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. For custom leather corsets, this can vary based on production capacity and complexity. Understanding lead times is crucial for inventory management and ensuring timely delivery to customers. -

Customization Options

– This term encompasses the various modifications a buyer can request for their corsets, including design, color, and size adjustments. Clear communication of customization options can significantly enhance customer satisfaction and allow businesses to cater to niche markets effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring their offerings meet market demands and maintain high standards of quality.

Navigating Market Dynamics and Sourcing Trends in the leather corset custom Sector

What Are the Current Market Dynamics and Key Trends in the Leather Corset Custom Sector?

The leather corset custom sector is experiencing a renaissance, driven by a blend of fashion innovation, cultural shifts, and technological advancements. A growing global interest in niche fashion markets, particularly in regions such as Africa, South America, the Middle East, and Europe, is creating new opportunities for B2B buyers. Custom leather corsets are increasingly sought after not just for their aesthetic appeal but also for their versatility in fashion statements—from high-end fashion to everyday wear.

Emerging trends include the rise of e-commerce platforms that allow for greater accessibility to bespoke products, enabling international buyers to source unique designs tailored to local tastes. Additionally, the integration of augmented reality (AR) technologies is enhancing the shopping experience, allowing customers to visualize corset designs virtually before making a purchase. This tech-driven approach not only improves customer satisfaction but also supports sellers in efficiently managing inventory and customizing orders.

Moreover, as the market grows, competition is intensifying. Buyers are advised to look for suppliers who offer transparency in their manufacturing processes and can demonstrate a commitment to quality and craftsmanship. The shift towards online marketplaces is also prompting businesses to adapt their strategies, focusing on digital marketing and social media engagement to reach broader audiences.

Illustrative image related to leather corset custom

How Is Sustainability and Ethical Sourcing Impacting the Leather Corset Custom Sector?

Sustainability and ethical sourcing are becoming non-negotiable factors in the leather corset custom market. The environmental impact of leather production, including water usage and greenhouse gas emissions, is prompting buyers to seek out suppliers who prioritize sustainable practices. This includes sourcing leather from certified tanneries that adhere to strict environmental regulations and animal welfare standards.

Furthermore, many brands are now offering ‘green’ certifications, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification. These certifications not only enhance the credibility of the suppliers but also appeal to a growing consumer base that values sustainability. B2B buyers should prioritize partnerships with manufacturers that emphasize transparency in their supply chains and utilize eco-friendly materials, such as vegetable-tanned leather or recycled components.

In addition, the trend towards minimalism and slow fashion is encouraging buyers to invest in high-quality, durable products that have a longer lifecycle, reducing waste and promoting responsible consumption. By aligning with suppliers who share these values, businesses can enhance their brand reputation and meet the demands of conscientious consumers.

What Is the Evolution of Leather Corsetry in the Context of B2B Buyers?

The evolution of leather corsetry can be traced back to the Victorian era when corsets were essential elements of women’s fashion. Initially designed for functional purposes, corsets have transitioned into fashion statements, symbolizing empowerment and body positivity in modern contexts. The leather corset, in particular, has emerged as a versatile item that can be styled for various occasions—from formal events to casual outings.

As fashion trends evolve, the demand for custom leather corsets has surged, reflecting a growing appreciation for individuality and bespoke craftsmanship. B2B buyers are increasingly looking for suppliers that can offer unique designs and personalization options, catering to specific market segments and cultural preferences. This shift signifies not just a change in consumer preferences but also highlights the importance of understanding historical contexts in product development and marketing strategies.

In conclusion, navigating the complexities of the leather corset custom sector requires a keen awareness of market dynamics, a commitment to sustainability, and an appreciation for the rich history that informs contemporary fashion trends.

Frequently Asked Questions (FAQs) for B2B Buyers of leather corset custom

-

How do I ensure the quality of custom leather corsets?

To ensure the quality of custom leather corsets, start by vetting suppliers with a proven track record in craftsmanship and material sourcing. Request samples to assess the leather quality, stitching, and overall design. Look for certifications or industry standards they adhere to, such as ISO. Additionally, consider visiting their production facilities if possible, or request detailed photos and descriptions of their manufacturing processes. Establishing clear communication and having a quality assurance process in place can help maintain consistent product standards. -

What is the best way to customize leather corsets for my market?

The best way to customize leather corsets is to analyze your target market’s preferences and trends. Conduct market research to identify popular styles, colors, and sizes among your customers. Collaborate with designers to create unique features that resonate with your audience, such as specific cuts, embellishments, or functional elements. Offering a range of sizes and allowing for bespoke measurements can also enhance customer satisfaction. Regularly seek feedback from your clients to refine your offerings continually. -

What are typical minimum order quantities (MOQs) for leather corsets?

Minimum order quantities (MOQs) for leather corsets can vary significantly depending on the supplier and the complexity of the designs. Typically, MOQs range from 50 to 200 pieces per style. It’s important to discuss these terms upfront with potential suppliers, as some may offer lower MOQs for established businesses or first-time orders. Ensure that the MOQ aligns with your budget and market demand to prevent excess inventory. Negotiating flexible terms may also be possible if you establish a strong partnership. -

What payment terms should I expect when sourcing leather corsets?

Payment terms when sourcing leather corsets can vary by supplier and region. Common terms include a deposit (usually 30-50%) upfront, with the balance due upon completion or before shipment. Some suppliers may offer net payment terms, allowing you to pay within a specified period after receiving the goods. Always clarify the payment method (e.g., bank transfer, credit card) and whether there are any additional fees for international transactions. Establishing clear payment terms in a contract can help prevent misunderstandings later. -

How can I find reliable suppliers for custom leather corsets?

To find reliable suppliers for custom leather corsets, start by leveraging online B2B marketplaces such as Alibaba or Global Sources. Attend trade shows and industry expos to connect with manufacturers in person. Networking through industry associations and forums can also lead to reputable contacts. Always conduct thorough due diligence by checking references, reading reviews, and requesting product samples. Establishing a good rapport and clear communication with potential suppliers will further enhance your sourcing experience. -

What logistics considerations should I keep in mind when importing leather corsets?

When importing leather corsets, consider shipping options, customs duties, and import regulations specific to your country. Choose a reliable freight forwarder who can assist with logistics and compliance. Be aware of lead times for production and shipping to manage inventory effectively. Additionally, factor in potential delays at customs, especially for products made from animal hides, which may require specific documentation. Planning ahead and maintaining open lines of communication with your supplier can help mitigate logistical challenges. -

What quality assurance practices should I implement for custom leather corsets?

Implementing quality assurance practices involves establishing clear standards for materials, production processes, and final inspection. Set up a quality control checklist that includes criteria such as leather grade, stitching integrity, and design accuracy. Conduct regular audits of your supplier’s production facility to ensure compliance with your standards. Consider third-party inspections before shipment to verify quality. Document any issues and maintain an open dialogue with your supplier to foster continuous improvement. -

How do I handle returns and exchanges for custom leather corsets?

Handling returns and exchanges for custom leather corsets requires a clear policy communicated to your customers. Specify conditions under which returns are accepted, such as defects or sizing issues. For custom orders, consider implementing a trial period or offering a fitting service to reduce the likelihood of returns. Establish a streamlined process for returns, including documentation and shipping instructions. Providing excellent customer service during this process can enhance customer loyalty and trust in your brand.

Top 1 Leather Corset Custom Manufacturers & Suppliers List

1. Dark Garden – Leather Corsets

Domain: darkgarden.com

Registered: 1997 (28 years)

Introduction: Leather Corsets from Dark Garden Unique Corsetry, Inc. include various styles such as the Signature Waspie, Corselette, Cincher, Cupid, Eden, Sweetheart, Valentine, Venus, Alexandra, Victorian, and Dollymop. Prices range from $1,445.00 to $4,245.00. Most corsets are made to order and feature options for underbust and overbust designs. The corsets are available in black leather and other custom fab…

Strategic Sourcing Conclusion and Outlook for leather corset custom

In today’s competitive fashion landscape, strategic sourcing of custom leather corsets offers significant advantages for B2B buyers. By focusing on high-quality materials and craftsmanship, businesses can cater to diverse consumer preferences, from classic elegance to edgy designs. The demand for custom leather corsets is rising, particularly among niche markets in Africa, South America, the Middle East, and Europe, where unique styles and personalized options are increasingly valued.

Collaboration with reputable manufacturers ensures not only superior product quality but also flexibility in design, enabling brands to differentiate themselves in a crowded marketplace. By leveraging insights from leading suppliers, businesses can streamline their sourcing strategies, reducing lead times and enhancing responsiveness to market trends.

Illustrative image related to leather corset custom

As we look to the future, the potential for growth in the leather corset sector remains robust. International buyers are encouraged to explore partnerships that prioritize innovation and sustainability in leather sourcing. Investing in these relationships will not only enhance product offerings but also build a loyal customer base. Embrace the opportunity to redefine your brand’s presence in this dynamic industry and position yourself as a leader in the custom leather corset market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather corset custom

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.