Introduction: Navigating the Global Market for seat upholstery fabric

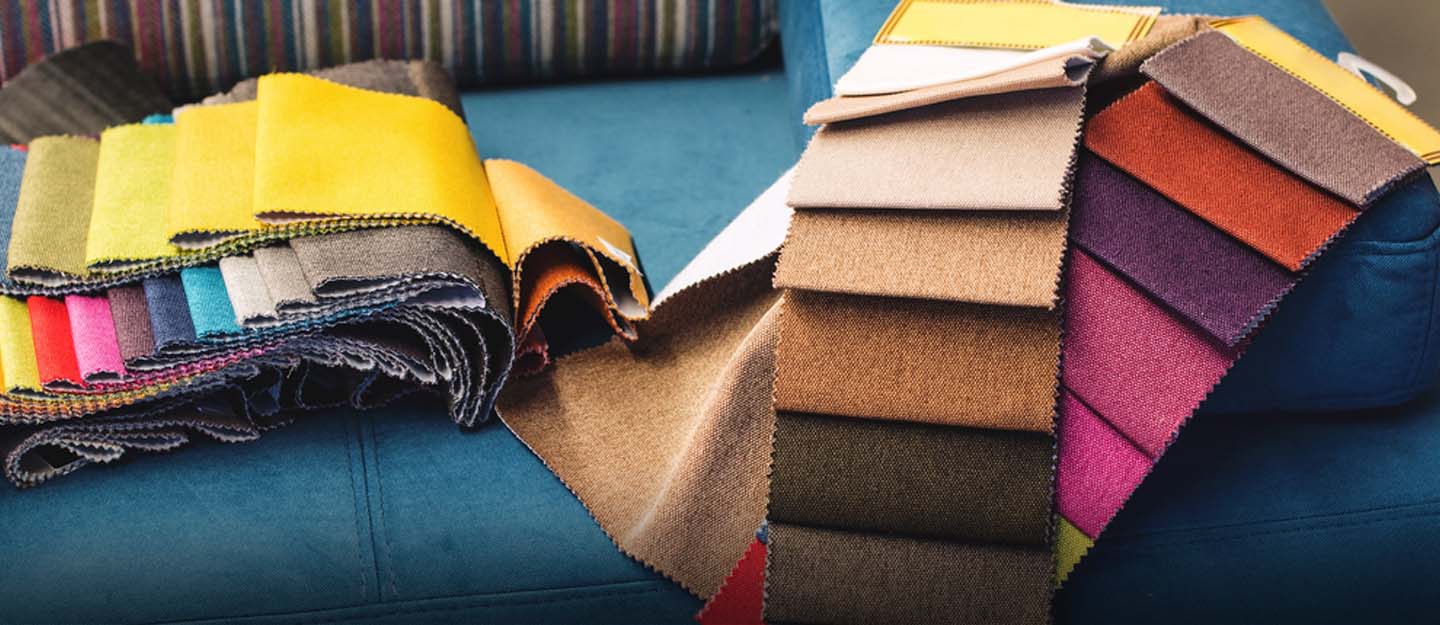

In an increasingly competitive landscape, sourcing the right seat upholstery fabric is crucial for businesses aiming to enhance comfort and durability in their seating solutions. Whether you are looking to furnish office spaces or design luxurious hotel lounges, the challenge of finding high-quality, cost-effective materials can be daunting. This guide provides a comprehensive overview of the global market for seat upholstery fabric, addressing key factors such as types of fabrics, their applications across various industries, effective supplier vetting, and cost considerations.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—will find actionable insights to navigate their purchasing decisions confidently. By understanding the nuances of upholstery fabric, from performance characteristics like stain resistance and durability to aesthetic considerations, this guide empowers businesses to make informed choices that align with their operational needs and customer expectations.

As you explore the diverse range of options available, you will gain the knowledge needed to select fabrics that not only meet functional requirements but also elevate the overall design of your seating solutions. Let this guide be your roadmap in the quest for the perfect seat upholstery fabric, ensuring your investments yield long-lasting value and satisfaction.

Table Of Contents

- Top 8 Seat Upholstery Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for seat upholstery fabric

- Understanding seat upholstery fabric Types and Variations

- Key Industrial Applications of seat upholstery fabric

- 3 Common User Pain Points for ‘seat upholstery fabric’ & Their Solutions

- Strategic Material Selection Guide for seat upholstery fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for seat upholstery fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘seat upholstery fabric’

- Comprehensive Cost and Pricing Analysis for seat upholstery fabric Sourcing

- Alternatives Analysis: Comparing seat upholstery fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for seat upholstery fabric

- Navigating Market Dynamics and Sourcing Trends in the seat upholstery fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of seat upholstery fabric

- Strategic Sourcing Conclusion and Outlook for seat upholstery fabric

- Important Disclaimer & Terms of Use

Understanding seat upholstery fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather | Durable, luxurious, and ages well; available in various finishes | High-end furniture, automotive, hospitality | Pros: Elegant appearance, high durability; Cons: Higher cost, requires maintenance. |

| Fabric (Polyester) | Versatile, stain-resistant, and easy to clean; available in many colors and patterns | Office seating, residential furniture | Pros: Cost-effective, wide variety; Cons: Less durable than leather, can wear out faster. |

| Vinyl | Waterproof, easy to clean, and often resembles leather | Healthcare, restaurants, and outdoor furniture | Pros: Budget-friendly, durable; Cons: Less breathable, may not have the same aesthetic appeal as leather. |

| Linen | Natural fiber, breathable, and soft to touch; available in various colors | Residential furniture, boutique hotels | Pros: Eco-friendly, comfortable; Cons: Prone to wrinkles and stains, less durable than synthetic options. |

| Canvas | Strong, durable, and typically made from cotton or a cotton blend | Outdoor furniture, casual seating | Pros: Highly durable, often machine washable; Cons: Limited color options, can fade in sunlight. |

What are the Key Characteristics of Leather Upholstery Fabric?

Leather upholstery is synonymous with luxury and durability. Its natural fibers provide a unique texture and aesthetic appeal, making it a favored choice in high-end furniture and automotive applications. When considering leather for B2B purchases, companies should evaluate the type of leather (e.g., full-grain, top-grain) and its maintenance requirements, as it may necessitate regular conditioning to prevent drying or cracking. While the initial investment is higher, leather’s longevity and timeless appeal often justify the cost for premium markets.

How Does Polyester Fabric Stand Out in Upholstery Choices?

Polyester upholstery fabric is widely used due to its versatility and affordability. Its stain-resistant properties make it ideal for high-traffic environments such as offices and homes. B2B buyers should consider the fabric’s double rub count, which indicates durability, and its colorfastness, especially for commercial applications. While polyester fabrics offer a broad range of designs, they may not provide the same level of durability as leather, making it essential for buyers to assess their specific usage needs.

Why Choose Vinyl Upholstery for Certain Applications?

Vinyl upholstery is a practical choice for industries that require easy maintenance and durability, such as healthcare and hospitality. Its waterproof nature and ease of cleaning make it suitable for environments prone to spills and stains. When purchasing vinyl upholstery, B2B buyers should evaluate the thickness and quality of the vinyl, as these factors directly influence its longevity. While cost-effective, vinyl may lack the breathability and aesthetic richness of natural materials, so it’s essential to balance functionality with design preferences.

Illustrative image related to seat upholstery fabric

What are the Benefits and Drawbacks of Linen Upholstery Fabric?

Linen upholstery fabric is known for its breathability and natural appeal, making it a popular choice for residential furniture and boutique hotels. Its soft texture provides a comfortable seating experience, but buyers should be aware of its tendency to wrinkle and stain. When sourcing linen, B2B buyers should consider the fabric’s weight and weave, as these characteristics affect durability. While linen offers an eco-friendly option, its maintenance and longevity may not match those of synthetic fabrics, requiring careful consideration for high-use environments.

How Does Canvas Fabric Perform in Upholstery Applications?

Canvas fabric is recognized for its strength and durability, often utilized in outdoor furniture and casual seating. Its robust nature allows it to withstand the elements, making it ideal for patio and recreational applications. B2B buyers should look for canvas treated for UV resistance to prevent fading and wear. While canvas is typically machine washable, its limited color palette and potential for fading in direct sunlight are factors to consider when selecting upholstery for various environments.

Key Industrial Applications of seat upholstery fabric

| Industry/Sector | Specific Application of Seat Upholstery Fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Upholstery for hotel lobby and restaurant seating | Enhances aesthetic appeal and comfort for guests | Durability, stain resistance, and easy maintenance |

| Automotive | Upholstery for car seats and interiors | Increases vehicle value and customer satisfaction | Material quality, compliance with safety standards |

| Healthcare | Upholstery for waiting room and examination chairs | Promotes hygiene and comfort in patient environments | Antimicrobial properties, ease of cleaning |

| Office Furniture | Upholstery for office chairs and collaborative spaces | Improves employee comfort and productivity | Ergonomics, durability, and aesthetic design |

| Public Transport | Upholstery for bus and train seating | Enhances passenger experience and safety | Fire resistance, durability, and ease of maintenance |

How is Seat Upholstery Fabric Used in the Hospitality Industry?

In the hospitality sector, seat upholstery fabric is essential for creating inviting environments in hotels and restaurants. Fabrics designed for high traffic areas must balance aesthetics with durability to withstand daily wear and tear. Buyers in this sector should prioritize stain-resistant materials that are easy to clean, as spills are common in dining settings. Additionally, fabrics should complement the overall interior design to enhance the guest experience, making sourcing from reputable suppliers crucial for ensuring quality and reliability.

What Role Does Seat Upholstery Fabric Play in the Automotive Sector?

In the automotive industry, seat upholstery fabric is a key component in enhancing the interior aesthetics and comfort of vehicles. High-quality fabrics not only improve the look of car interiors but also add value to the vehicle itself. Buyers must consider factors such as material durability, ease of cleaning, and compliance with safety standards, including fire resistance. With a growing demand for eco-friendly materials, sourcing sustainable options can also appeal to environmentally conscious consumers, especially in regions like Europe and South America.

Why is Seat Upholstery Fabric Important in Healthcare Settings?

Healthcare facilities utilize seat upholstery fabric for waiting rooms and examination chairs, where hygiene and comfort are paramount. Fabrics with antimicrobial properties are essential to minimize the risk of infections in patient environments. Buyers in this sector should focus on materials that are easy to clean, as frequent sanitation is required. Additionally, the fabric’s comfort level can significantly impact patient experiences, making it vital to choose upholstery that meets these specific needs while adhering to industry regulations.

How Does Seat Upholstery Fabric Enhance Office Furniture?

In office environments, seat upholstery fabric is crucial for enhancing employee comfort and productivity. Ergonomically designed chairs with high-quality upholstery can reduce fatigue and improve focus during long working hours. Buyers should consider the durability of the fabric, as well as its aesthetic appeal to align with corporate branding. Furthermore, materials that are easy to maintain and clean can contribute to a healthier workplace, making it essential for international buyers to source fabrics that meet these operational requirements.

What Are the Key Considerations for Upholstery Fabric in Public Transport?

Seat upholstery fabric in public transport, such as buses and trains, plays a vital role in passenger comfort and safety. Fabrics must be durable and resistant to wear, as well as fire-resistant to comply with safety regulations. Buyers should focus on sourcing materials that are easy to maintain and can withstand frequent cleaning, as public transport seating experiences high levels of usage. Additionally, selecting fabrics that enhance passenger comfort can lead to a better travel experience, making this a critical area for sourcing decisions.

3 Common User Pain Points for ‘seat upholstery fabric’ & Their Solutions

Scenario 1: Balancing Durability and Aesthetics in Upholstery Choices

The Problem: B2B buyers often struggle to find upholstery fabrics that meet both durability and aesthetic requirements. In industries like hospitality or healthcare, where furniture is subjected to heavy use, selecting fabrics that can withstand wear and tear is critical. However, these fabrics must also align with the brand’s image and customer expectations for style and comfort. Buyers may feel pressured to compromise on one aspect, leading to unsatisfactory results that could impact customer satisfaction and brand perception.

The Solution: To address this challenge, buyers should prioritize sourcing upholstery fabrics that are specifically designed for high-traffic environments. Look for materials labeled as “performance fabrics,” which are engineered to resist stains, fading, and abrasion while offering a wide range of styles and colors. For instance, selecting fabrics from manufacturers that provide certifications (like double rub counts) can help gauge durability. Buyers should also consult with fabric suppliers to understand the characteristics of different weaves and blends, ensuring that they choose products that not only meet practical needs but also enhance the visual appeal of the space. Investing in samples and conducting side-by-side comparisons can also facilitate informed decision-making that balances durability and style.

Scenario 2: Managing Supply Chain Disruptions and Lead Times

The Problem: In the global market, B2B buyers often face unpredictable supply chain disruptions that can delay the procurement of upholstery fabrics. Factors such as geopolitical issues, natural disasters, or even pandemic-related restrictions can lead to extended lead times. This unpredictability can hinder project timelines, disrupt production schedules, and ultimately affect customer satisfaction. Buyers may find themselves scrambling to find alternative sources, leading to rushed decisions that could compromise quality.

The Solution: To mitigate these risks, B2B buyers should establish relationships with multiple fabric suppliers across different regions. This diversification can provide a safety net in case one supplier experiences disruptions. Additionally, implementing a just-in-time inventory strategy can help manage stock levels without overcommitting to any single supplier. Buyers should regularly communicate with suppliers about potential delays and lead times, allowing them to plan ahead and make adjustments as needed. Utilizing technology, such as supply chain management software, can also enhance visibility into order statuses and help buyers anticipate challenges before they arise.

Scenario 3: Understanding Fabric Maintenance and Longevity

The Problem: Many B2B buyers are unaware of the specific maintenance requirements for different upholstery fabrics, which can lead to premature wear and tear. For instance, neglecting proper cleaning methods or using the wrong products can damage the fabric, resulting in costly replacements and unhappy customers. Buyers may feel overwhelmed by the array of cleaning options available and may lack the knowledge to choose the best practices for their specific upholstery selections.

The Solution: To ensure longevity and maintain the appearance of seat upholstery fabrics, buyers should invest time in understanding the care instructions provided by manufacturers. This includes knowing the cleaning codes (such as W for water-based cleaners, S for solvent-based, etc.) and selecting appropriate cleaning products. Buyers should also consider training staff on proper maintenance protocols to ensure consistency in care. Offering customers guidance on how to maintain their upholstery can enhance the overall customer experience and reduce the frequency of replacements. Additionally, exploring fabrics that are inherently easy to clean and maintain, such as those with stain-resistant treatments, can simplify upkeep and prolong the life of the investment.

Strategic Material Selection Guide for seat upholstery fabric

What Are the Key Properties of Common Materials Used for Seat Upholstery Fabric?

When selecting materials for seat upholstery fabric, various factors such as durability, comfort, and ease of maintenance come into play. Here, we analyze four commonly used materials: polyester, leather, vinyl, and linen, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Polyester Perform as a Seat Upholstery Material?

Polyester is a synthetic fabric known for its durability and versatility. It has excellent resistance to wrinkles, fading, and abrasion, making it suitable for high-traffic areas. Polyester upholstery can withstand a temperature range of -40°F to 140°F (-40°C to 60°C) and offers a good level of stain resistance, which is essential for maintaining a clean appearance.

Pros: Polyester is cost-effective and widely available, making it an attractive option for bulk purchases. It is also easy to clean and dries quickly, which is beneficial for environments where spills are common.

Illustrative image related to seat upholstery fabric

Cons: While polyester is durable, it can be less breathable than natural fibers, leading to discomfort in hot climates. Additionally, it may not have the same luxurious feel as other materials like leather.

Impact on Application: Polyester is compatible with various cleaning agents, but care must be taken to avoid harsh chemicals that could degrade the fabric over time.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding textile safety and environmental standards. For instance, certifications like Oeko-Tex Standard 100 may be relevant in Europe.

What Advantages Does Leather Offer for Upholstery?

Leather is a premium upholstery material that provides a classic and sophisticated look. It is known for its durability and resistance to wear and tear, with a typical lifespan that can exceed ten years with proper care. Leather can handle high pressure and temperature variations, making it suitable for various climates.

Pros: Leather is easy to clean and maintain, often requiring just a damp cloth. It also ages well, developing a unique patina over time, which can enhance its aesthetic appeal.

Illustrative image related to seat upholstery fabric

Cons: The initial cost of leather is significantly higher than synthetic options, which may deter budget-conscious buyers. Additionally, leather can be sensitive to scratches and may require conditioning to prevent drying and cracking.

Impact on Application: Leather is compatible with various cleaning products, but buyers should avoid using harsh chemicals that could damage the finish.

Considerations for International Buyers: Buyers should be aware of ethical sourcing practices and compliance with international regulations regarding animal welfare. Certifications like the Leather Working Group (LWG) can be important for buyers in Europe.

Why Choose Vinyl for Seat Upholstery Fabric?

Vinyl is a synthetic alternative to leather, offering a similar aesthetic at a lower cost. It is highly resistant to moisture, stains, and fading, making it ideal for environments where spills are frequent, such as restaurants and cafes.

Pros: Vinyl is easy to clean and maintain, often requiring only soap and water. Its durability makes it suitable for high-traffic areas, and it can withstand a wide range of temperatures.

Cons: While vinyl is cost-effective, it may not offer the same level of comfort or breathability as natural materials. Over time, it can become less flexible and may crack if exposed to extreme temperatures.

Impact on Application: Vinyl is compatible with most cleaning agents, but buyers should avoid abrasive cleaners that could scratch the surface.

Considerations for International Buyers: Compliance with safety standards, such as those set by ASTM or DIN, is crucial. Buyers should also consider the environmental impact of vinyl production and disposal.

What Makes Linen a Unique Choice for Upholstery?

Linen is a natural fabric known for its breathability and moisture-wicking properties. It is particularly suitable for warm climates, providing comfort and a classic look. Linen can handle moderate pressure and temperature variations but is less durable than synthetic options.

Pros: Linen is biodegradable and environmentally friendly, appealing to buyers focused on sustainability. It also has a unique texture that adds character to upholstery.

Cons: Linen is prone to wrinkling and may require more maintenance than synthetic fabrics. It can also be less resistant to stains and fading.

Impact on Application: Linen is compatible with mild cleaning agents, but care must be taken to avoid harsh chemicals that could damage the fibers.

Illustrative image related to seat upholstery fabric

Considerations for International Buyers: Buyers should ensure compliance with eco-friendly certifications and consider local preferences for natural materials, especially in markets like Europe.

Summary Table of Material Selection for Seat Upholstery Fabric

| Material | Typical Use Case for seat upholstery fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | High-traffic areas like offices and homes | Durable and cost-effective | Less breathable than natural fibers | Low |

| Leather | Premium seating in hotels and restaurants | Luxurious feel and durability | High initial cost and maintenance | High |

| Vinyl | Cafes and dining establishments | Easy to clean and moisture-resistant | Less breathable and can crack over time | Med |

| Linen | Residential seating in warm climates | Breathable and environmentally friendly | Prone to wrinkling and staining | Med |

This guide serves as a strategic resource for B2B buyers looking to make informed decisions regarding seat upholstery fabric materials, ensuring they consider performance, cost, and compliance factors specific to their markets.

In-depth Look: Manufacturing Processes and Quality Assurance for seat upholstery fabric

What Are the Main Stages in the Manufacturing Process of Seat Upholstery Fabric?

The manufacturing of seat upholstery fabric involves several critical stages that ensure the final product meets the desired quality and performance standards. Understanding these stages is essential for B2B buyers looking to source high-quality materials.

Material Preparation: What Does It Entail?

The first step in manufacturing upholstery fabric is material preparation, which involves selecting and preparing the raw materials. Common materials used include cotton, polyester, and blends that offer durability and aesthetic appeal. During this phase, manufacturers assess the fiber quality, colorfastness, and texture.

In some cases, pre-treatment processes such as dyeing or applying protective coatings are performed to enhance the fabric’s properties. For instance, stain-resistant finishes may be applied to make the fabric more suitable for high-traffic areas. Buyers should inquire about the sourcing and treatment processes of raw materials to ensure they align with their quality expectations.

Forming: How Is the Fabric Created?

The forming stage involves weaving or knitting the prepared fibers into fabric. The choice of technique—woven, knitted, or non-woven—depends on the intended use and required characteristics of the upholstery fabric.

Woven fabrics, for example, are popular for their strength and durability, while knitted fabrics provide more stretch and comfort. Advanced techniques such as jacquard weaving can create intricate patterns and textures, adding value to the end product. B2B buyers should consider the manufacturing techniques that best suit their market needs, as these will influence both the cost and performance of the upholstery fabric.

Assembly: What Happens in This Stage?

After the fabric is formed, it goes through an assembly process where the fabric is cut and sewn into specific patterns and dimensions required for various seating applications. This stage often involves the use of automated cutting machines and sewing equipment to ensure precision and efficiency.

Quality control checkpoints are integrated into this stage to inspect the fabric for any defects, such as misalignment or flaws in stitching. Buyers should verify that suppliers implement rigorous checks during assembly to maintain high standards.

Finishing: What Enhancements Are Applied?

The finishing stage is crucial for enhancing the aesthetic and functional properties of the upholstery fabric. This may include processes such as heat-setting, additional dyeing, or applying surface treatments that improve water and stain resistance.

Finishing techniques also play a vital role in determining the fabric’s texture and hand feel, which are important factors for customer satisfaction. B2B buyers should inquire about the specific finishing processes used by suppliers to ensure the fabrics meet their quality and performance requirements.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance (QA) is integral to the manufacturing process of seat upholstery fabric, ensuring that the final product adheres to international standards and meets customer expectations.

Which International Standards Should Be Considered?

International standards such as ISO 9001 are critical in guiding manufacturers in establishing effective quality management systems. Compliance with ISO standards indicates that a manufacturer has implemented processes that consistently meet customer and regulatory requirements.

Illustrative image related to seat upholstery fabric

In addition to ISO 9001, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) may apply depending on the target market and application of the upholstery fabric. Buyers should request documentation proving compliance with these standards to ensure reliability and safety.

What Are the Key Quality Control Checkpoints?

To maintain high-quality standards, manufacturers typically implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified quality criteria.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are performed to monitor the manufacturing process and identify any deviations from quality standards.

-

Final Quality Control (FQC): Before the fabric is packaged and shipped, a comprehensive inspection is conducted to assess the finished product for defects, color consistency, and overall quality.

B2B buyers should inquire about the specific quality control measures employed by suppliers and request access to inspection reports to verify adherence to quality standards.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is essential to mitigate risks associated with sourcing upholstery fabric.

What Methods Can Be Used for Verification?

-

Audits: Conducting regular audits of suppliers helps buyers assess their compliance with quality standards and manufacturing processes. These audits can be performed by the buyers themselves or by third-party auditors specializing in quality assurance.

-

Quality Reports: Suppliers should provide detailed quality reports that outline inspection results, compliance with standards, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the manufacturing process and product quality can provide an unbiased assessment. This is particularly beneficial for buyers who are unable to visit suppliers’ facilities.

-

Certifications: Buyers should request copies of relevant certifications that demonstrate compliance with international standards, as well as any additional quality assurance programs implemented by the supplier.

What Are the Unique QC Considerations for International Buyers?

International buyers must consider various nuances in quality control when sourcing upholstery fabric from different regions. These can include:

-

Cultural Differences: Understanding local manufacturing practices and quality expectations can help buyers navigate potential discrepancies in quality.

-

Regulatory Compliance: Different countries may have specific regulations regarding materials used in upholstery fabrics, such as fire safety standards or chemical restrictions. Buyers should ensure that their suppliers comply with relevant regulations in their target markets.

-

Supply Chain Transparency: Establishing transparency in the supply chain can enhance trust between buyers and suppliers, ensuring that quality assurance processes are upheld throughout the production cycle.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with seat upholstery fabric, B2B buyers can make informed decisions that align with their business goals and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘seat upholstery fabric’

In the competitive landscape of seat upholstery fabric sourcing, making informed decisions is crucial for B2B buyers. This guide provides a step-by-step checklist designed to streamline your procurement process, ensuring you select the best materials and suppliers for your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the type of fabric required based on usage—commercial, residential, or automotive—and consider factors such as durability, stain resistance, and maintenance requirements. For instance, fabrics intended for high-traffic areas should have a higher double rub count for enhanced durability.

Step 2: Identify Your Budget Constraints

Before reaching out to suppliers, outline your budget constraints. This will help narrow down options and facilitate negotiations. Be aware of the total cost of ownership, including shipping, tariffs, and potential import taxes, which can significantly impact your final expenditure. Setting a budget also aids in assessing the cost-benefit ratio of different fabric types.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in upholstery fabrics. Look for companies with a robust catalog that includes a variety of styles and functionalities. Utilize online platforms, trade shows, and industry directories to gather a list of suppliers that align with your specifications. Pay attention to their market reputation and customer reviews.

Step 4: Evaluate Supplier Certifications

Supplier certifications can indicate quality assurance and compliance with international standards. Verify if the supplier holds relevant certifications such as ISO 9001 for quality management or Oeko-Tex for eco-friendly materials. These certifications can provide assurance of the fabric’s safety and durability, which is particularly important for sectors like hospitality and healthcare.

Step 5: Request Samples for Evaluation

Once you have shortlisted suppliers, request fabric samples to assess the quality and feel of the materials. This hands-on evaluation is critical to ensure the fabric meets your expectations in terms of color, texture, and durability. Look for samples that reflect the actual conditions the fabric will face in its intended application.

Step 6: Negotiate Terms and Conditions

Engage in discussions with your shortlisted suppliers to negotiate pricing, payment terms, and delivery schedules. Clear communication about your expectations can help build a strong partnership. Ensure that all terms are documented to avoid misunderstandings later. Be open to discussing bulk discounts or loyalty incentives.

Step 7: Finalize the Purchase and Establish a Relationship

After agreeing on terms, finalize your purchase. Establishing a strong relationship with your supplier can lead to better service, favorable pricing in the future, and priority access to new products. Regularly communicate with your supplier to stay updated on new offerings and industry trends that may benefit your business.

By following this structured checklist, B2B buyers can enhance their sourcing strategy for seat upholstery fabric, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for seat upholstery fabric Sourcing

What Are the Key Cost Components in Seat Upholstery Fabric Sourcing?

When sourcing seat upholstery fabric, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of fabric significantly influences the cost. Fabrics such as polyester or polypropylene are generally more affordable than high-end materials like leather or specialty weaves. The price can range from as low as $2 per yard for basic materials to over $30 for premium options.

-

Labor: Labor costs can vary depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but it’s crucial to assess the quality of workmanship.

-

Manufacturing Overhead: This includes costs associated with running the production facilities, such as utilities, equipment maintenance, and workforce management. Efficient factories with lower overhead can offer better pricing.

-

Tooling: Custom designs or specialized patterns may incur tooling costs, which can add to the overall price. Buyers should consider whether the investment in tooling aligns with their volume needs.

-

Quality Control (QC): Quality assurance processes ensure the fabric meets specifications and standards. While this may increase costs, it’s essential for preventing defects and ensuring customer satisfaction.

-

Logistics: Shipping and handling fees must also be factored in, particularly for international shipments. These costs can vary widely based on distance, shipping method, and customs duties.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market standards for margins can help buyers negotiate better deals.

How Do Price Influencers Affect Upholstery Fabric Costs?

Several factors can influence the pricing of upholstery fabric, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. Suppliers may have a MOQ that can impact your total expenditure.

-

Specifications and Customization: Customized fabrics or unique specifications can significantly increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Fabrics with certifications (e.g., flame retardant, eco-friendly) typically command higher prices. Buyers should assess the necessity of such certifications based on their target market.

-

Supplier Factors: The supplier’s reputation, location, and production capacity can influence pricing. Established suppliers may offer more reliability, but at a premium.

-

Incoterms: The terms of sale can affect the total cost. Understanding whether costs include shipping, insurance, and duties can help buyers better assess the total landed cost of their orders.

What Are the Best Practices for Negotiating Upholstery Fabric Prices?

To optimize costs in upholstery fabric sourcing, consider the following tips:

-

Conduct Market Research: Familiarize yourself with market rates and supplier offerings to strengthen your negotiating position. Knowing the average prices can help you identify reasonable offers.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as durability, maintenance, and potential replacement costs. Fabrics that may seem expensive upfront can offer savings in the long run through lower maintenance and longer lifespans.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster trust, making suppliers more willing to accommodate requests.

-

Understand Regional Pricing Nuances: Pricing structures can differ significantly between regions. For international buyers, understanding local market dynamics, currency fluctuations, and economic conditions is crucial for effective negotiation.

-

Request Samples: Before committing to a large order, request samples to evaluate quality. This can prevent costly mistakes and ensure the fabric meets your standards.

Conclusion

Sourcing seat upholstery fabric involves navigating a complex cost structure influenced by various factors. By understanding these components and employing strategic negotiation tactics, international B2B buyers can optimize their purchasing decisions, ensuring both quality and cost-effectiveness in their upholstery projects. Always keep in mind that prices can vary based on market conditions, and the figures provided are indicative.

Alternatives Analysis: Comparing seat upholstery fabric With Other Solutions

In the competitive landscape of upholstery solutions, it’s essential for B2B buyers to explore various alternatives to traditional seat upholstery fabric. This analysis highlights key alternatives that can meet similar needs while considering performance, cost, ease of implementation, maintenance, and best use cases. Understanding these options enables buyers to make informed decisions tailored to their specific requirements.

| Comparison Aspect | Seat Upholstery Fabric | Alternative 1: Vinyl Upholstery | Alternative 2: Leather Upholstery |

|---|---|---|---|

| Performance | Soft, comfortable, variety of designs | Durable, water-resistant, easy to clean | Luxurious, durable, develops a patina over time |

| Cost | Moderate, varies by fabric type | Generally lower cost than leather | Higher initial cost, but lasts longer |

| Ease of Implementation | Requires sewing, may need special tools | Easy to cut and apply, no special tools needed | Requires skilled labor for installation |

| Maintenance | Requires regular cleaning and care | Low maintenance, easy to wipe clean | Needs conditioning and regular upkeep |

| Best Use Case | Residential and commercial furniture | High-traffic areas, outdoor settings | Luxury settings, high-end furniture |

What are the Benefits and Drawbacks of Vinyl Upholstery as an Alternative?

Vinyl upholstery offers a compelling alternative for B2B buyers looking for durability and ease of care. Its water-resistant properties make it suitable for high-traffic areas, such as restaurants and waiting rooms. Additionally, vinyl is available at a lower cost than leather, making it an attractive option for budget-conscious projects. However, it may lack the comfort and aesthetic appeal of fabric or leather, potentially affecting the overall ambiance of luxury environments.

How Does Leather Upholstery Compare to Seat Upholstery Fabric?

Leather upholstery is synonymous with luxury and durability, making it a favored choice for high-end applications. It ages beautifully, developing a unique patina that enhances its character over time. Leather’s durability also means it can withstand significant wear, making it suitable for office chairs and upscale lounges. However, the higher initial cost can be a barrier for some businesses, and it requires specific maintenance to keep it looking its best. Additionally, leather can be less comfortable in extreme temperatures compared to softer fabrics.

How Can B2B Buyers Choose the Right Upholstery Solution for Their Needs?

When selecting the appropriate upholstery solution, B2B buyers should consider the specific application and environment where the upholstery will be used. For high-traffic areas requiring low maintenance, vinyl may be the best option. However, if the goal is to convey luxury and comfort, leather could be the ideal choice. Ultimately, the right solution will depend on balancing factors such as budget, desired aesthetics, and the level of maintenance the business is prepared to commit to. By assessing these elements, buyers can make well-informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for seat upholstery fabric

What Are the Key Technical Properties of Seat Upholstery Fabric?

When selecting seat upholstery fabric, understanding its technical properties is crucial for ensuring durability, comfort, and aesthetic appeal. Here are some essential specifications to consider:

Illustrative image related to seat upholstery fabric

1. Material Composition

The fabric’s material composition directly impacts its performance, feel, and maintenance. Common materials include polyester, polypropylene, and natural fibers like cotton or linen. For instance, polyester blends are often favored for their stain resistance and durability, making them ideal for high-traffic environments. B2B buyers should assess material properties to align with their target market’s needs, whether for luxury seating or commercial applications.

2. Fabric Weight

Measured in grams per square meter (gsm), fabric weight indicates the density and sturdiness of the upholstery. Heavier fabrics are typically more durable and suitable for furniture that experiences frequent use, while lighter fabrics may be more appropriate for decorative pieces. Understanding fabric weight helps in determining the longevity of the upholstery and its suitability for various applications.

3. Abrasion Resistance (Double Rubs)

Abrasion resistance is quantified through a test that measures the number of double rubs a fabric can withstand before showing signs of wear. Fabrics rated for 30,000 double rubs or higher are generally suitable for commercial use, while those with lower ratings may be better for low-traffic areas. This specification is vital for B2B buyers to ensure that the upholstery can endure the expected usage without deteriorating quickly.

4. Colorfastness

Colorfastness refers to the fabric’s ability to maintain its color when exposed to light, washing, or rubbing. This property is particularly important for upholstery that will be placed in bright environments or subjected to frequent cleaning. Fabrics with high colorfastness ratings will provide longer-lasting aesthetic appeal, reducing the need for replacements and ensuring customer satisfaction.

5. Flame Resistance

In many industries, especially commercial seating, compliance with flame resistance standards is critical. Fabrics may need to meet specific fire safety regulations, which vary by region and application. Understanding these requirements is essential for B2B buyers to ensure that their products are safe and compliant, particularly in public spaces.

What Are Common Trade Terms Related to Seat Upholstery Fabric?

Familiarity with industry jargon is essential for effective communication and negotiation in the upholstery market. Here are key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the upholstery industry, this may involve sourcing fabric from manufacturers that supply to furniture brands. Understanding OEM relationships can help buyers identify reliable suppliers and establish partnerships.

Illustrative image related to seat upholstery fabric

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cost efficiency. Buyers should negotiate MOQs to align with their purchasing capacity while ensuring they can meet market demand.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific quantities and specifications of products. Issuing an RFQ allows B2B buyers to compare costs and terms from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international trade. These terms cover aspects such as shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers engaged in global procurement to manage risks and costs effectively.

Illustrative image related to seat upholstery fabric

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the products. This term is crucial for planning inventory and ensuring timely delivery to customers. B2B buyers should assess lead times when selecting suppliers to maintain efficient supply chain operations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding seat upholstery fabric, leading to better product offerings and enhanced customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the seat upholstery fabric Sector

What Are the Current Market Dynamics and Key Trends in the Seat Upholstery Fabric Sector?

The global seat upholstery fabric market is witnessing significant growth, driven by rising consumer demand for aesthetic and functional furniture solutions across various sectors, including automotive, hospitality, and residential. Key trends include the increasing integration of technology in fabric production, such as digital printing and smart textiles that enhance durability and comfort. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on sourcing fabrics that not only meet aesthetic preferences but also comply with international quality standards.

Emerging sourcing trends highlight the growing importance of direct relationships between manufacturers and buyers, facilitated by digital platforms that streamline procurement processes. This shift towards direct sourcing enables international buyers to reduce costs, improve lead times, and ensure product authenticity. Furthermore, the demand for multifunctional fabrics, such as stain-resistant and easy-to-clean materials, is on the rise, especially in high-traffic areas like restaurants and public transport. Buyers are also increasingly looking for customization options that cater to regional tastes and preferences.

Additionally, the market is characterized by a competitive landscape with a mix of established players and new entrants, making it crucial for buyers to stay informed about supplier capabilities and innovations. As the sector evolves, understanding these dynamics will be essential for making informed purchasing decisions that align with both business objectives and consumer expectations.

How Is Sustainability and Ethical Sourcing Influencing B2B Decisions in the Upholstery Fabric Market?

Sustainability has emerged as a key consideration for B2B buyers in the seat upholstery fabric sector, particularly as environmental regulations tighten globally. The environmental impact of fabric production, including water usage, chemical runoff, and waste generation, has prompted buyers to seek suppliers that prioritize sustainable practices. This includes opting for materials that are recycled, biodegradable, or sourced from renewable resources.

Ethical supply chains are becoming increasingly important, with buyers demanding transparency regarding labor practices and sourcing origins. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® are gaining traction as buyers look for assurance that their fabrics are produced without harmful chemicals and under fair labor conditions. Moreover, the adoption of green materials not only meets regulatory demands but also enhances brand reputation, appealing to eco-conscious consumers.

In regions like Africa and South America, where local economies can benefit significantly from sustainable practices, buyers are finding opportunities to support local artisans and industries. This not only fosters community development but also aligns with global sustainability goals, making ethical sourcing a win-win for both buyers and suppliers.

What Is the Brief Evolution and History of the Upholstery Fabric Sector?

The upholstery fabric sector has evolved significantly from its humble beginnings, where materials were primarily handmade and locally sourced. Historically, fabrics such as wool, cotton, and linen dominated the market, with artisans creating bespoke pieces for individual clients. The industrial revolution marked a pivotal shift, introducing mechanized production and synthetic materials that made upholstery more accessible and affordable.

In recent decades, advancements in technology have transformed the sector, allowing for the development of innovative fabrics that combine aesthetic appeal with enhanced durability and functionality. The introduction of performance fabrics, which are stain-resistant and easy to maintain, has revolutionized the market, catering to the demands of modern consumers and businesses alike. This evolution continues as the industry adapts to changing consumer preferences, sustainability imperatives, and technological advancements, setting the stage for a dynamic future in seat upholstery fabrics.

Frequently Asked Questions (FAQs) for B2B Buyers of seat upholstery fabric

-

How do I select the right upholstery fabric for my seating needs?

Selecting the right upholstery fabric for seating requires consideration of several factors. Evaluate the intended use of the furniture, such as residential or commercial applications, which influences durability needs. Look for fabrics that offer stain resistance and ease of cleaning, especially for high-traffic areas. Consider the fabric’s texture, color, and pattern to ensure it aligns with your design vision. Lastly, review the fabric’s durability ratings, such as double rubs, which indicate its resilience against wear and tear. -

What are the most durable upholstery fabrics for commercial seating?

The most durable upholstery fabrics for commercial seating include synthetic options like polyester and polypropylene. These materials are often treated to resist stains and fading, making them ideal for high-use environments. Additionally, fabrics like vinyl and leather provide both durability and a premium appearance. It’s crucial to choose fabrics with a high Martindale or Wyzenbeek rating, indicating their ability to withstand abrasion and maintain their appearance over time. -

What customization options are typically available for upholstery fabrics?

Many suppliers offer a range of customization options for upholstery fabrics, including color, pattern, and texture. You can often request specific fabric blends to meet performance requirements, such as increased water resistance or UV protection for outdoor use. Some manufacturers allow for custom printing of designs or logos on fabrics, which can enhance branding efforts. Always confirm the minimum order quantities (MOQs) for customized products, as these may vary significantly. -

What are the payment terms usually offered by upholstery fabric suppliers?

Payment terms can vary widely among upholstery fabric suppliers, but common practices include net 30 or net 60 days for established business relationships. Some suppliers may require a deposit upfront, especially for large orders or custom fabrics. International buyers should inquire about payment methods, such as letters of credit or PayPal, to ensure secure transactions. It’s also wise to clarify any potential currency exchange fees and the implications for overall cost. -

How can I ensure the quality of upholstery fabric before purchasing?

To ensure fabric quality, request samples from potential suppliers before placing a bulk order. This allows you to evaluate the fabric’s texture, color accuracy, and overall feel. Additionally, ask for certifications or test results demonstrating the fabric’s durability, such as abrasion resistance and fire safety ratings. Establish a quality assurance process that includes inspections upon delivery to confirm that the received goods meet your specifications. -

What logistics considerations should I keep in mind when sourcing upholstery fabric internationally?

When sourcing upholstery fabric internationally, consider shipping costs, lead times, and potential customs duties. Work with suppliers who have experience in international shipping to ensure compliance with local regulations. It’s essential to factor in the shipping timeline to avoid delays in your production schedule. Additionally, establish clear communication regarding the Incoterms used, which define the responsibilities of buyers and sellers in the shipping process. -

What are the common minimum order quantities (MOQs) for upholstery fabrics?

Minimum order quantities (MOQs) for upholstery fabrics can vary by supplier and fabric type. Generally, standard fabrics might have MOQs ranging from 50 to 100 yards, while custom fabrics can require higher quantities, sometimes exceeding 500 yards. It’s crucial to confirm MOQs upfront to ensure they align with your purchasing needs. Some suppliers may offer flexibility on MOQs for repeat customers or large contracts, so negotiating terms could be beneficial. -

How do I vet suppliers when sourcing upholstery fabric?

Vetting suppliers is essential to ensure reliability and quality. Start by researching their industry reputation, checking online reviews, and requesting references from other clients. Verify their manufacturing capabilities, lead times, and compliance with international quality standards. Additionally, consider visiting their facility if possible or conducting a virtual audit to assess their operations. Establishing a strong communication channel and understanding their customer service approach can also help gauge their reliability.

Top 8 Seat Upholstery Fabric Manufacturers & Suppliers List

1. King Cotton – Upholstery Fabrics Collection

Domain: kingcottonfabrics.com

Registered: 2011 (14 years)

Introduction: Upholstery Fabrics collection featuring 829 products including various styles such as Abstract, Animals, Animal Prints, Birds, Floral, Geometric (Dots, Herringbone, Houndstooth), High Performance, Imported Linen, Linen, Matelasse’, Metallic, Solid, Stripes, Plaids, Checks, Textured & Tweed, Toile, Velvet. Products available in multiple colors including White, Ivory, Natural, Brown, Grey, Black, Re…

2. Revolution Fabrics – Chair Upholstery Fabric

Domain: revolutionfabrics.com

Registered: 2015 (10 years)

Introduction: Chair Upholstery Fabric from Revolution Fabrics is designed for durability and easy maintenance. Key features include:

– Stain-resistant woven fabrics suitable for chairs, seats, benches, and barstools.

– Bleach cleanable, allowing for easy cleanup of spills, even on dark colors.

– Crafted for heavy use, making them ideal for busy dining rooms and kitchens.

– Soft yet sturdy surface for comfor…

3. TopFabric – Fast Delivery & Easy Returns

Domain: topfabric.com

Registered: 2003 (22 years)

Introduction: This company, TopFabric – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

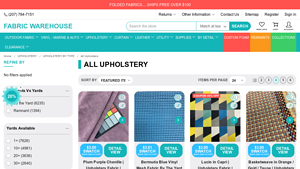

4. Fabric Warehouse – Upholstery Fabric By The Yard

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Upholstery Fabric By The Yard – All Brands, Themes, Colors. Free shipping on orders over $100. Categories include Outdoor Fabric, Vinyl, Marine & Auto Upholstery, Curtain, Leather, Utility Supplies, and Clearance. Fabrics available in Remnants and Yards with various color options such as Beige, Black, Blue, Bronze, Brown, Gold, Gray, Green, Ivory, Khaki, Orange, Pink, Purple, Red, Silver. Fabric w…

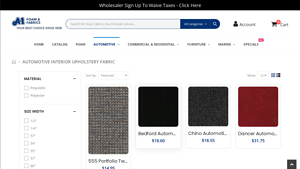

5. A1 Foam and Fabrics – 555 Portfolio Tweed Collection

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Introduction: {“products”:[{“name”:”555 Portfolio Tweed Collection”,”market_applications”:”Automotive, RV, Furniture”,”characteristics”:{“abrasion_resistance”:”50,000+ DR #10 Cotton Duck”,”flame_retardancy”:[“California T.B. 117 Section E-Class 1(Pass)”,”NFPA 260-Class 1 (Pass)”,”UFAC Class 1 (Pass)”],”lightfastness”:”UV Stable”},”price”:”$14.95″},{“name”:”Bedford Automotive Velvet”,”market_applications”:”Autom…

6. Decorative Fabrics Direct – Upholstery Fabrics

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Upholstery Fabric – Decorative Fabrics Direct offers a wide range of upholstery fabrics for home decor, available by the yard. Key features include:

– Free Shipping on most orders over $199 with coupon code: SHIPFREE.

– Extensive selection of fabrics categorized by use (interior, outdoor), color, pattern, type, and brand.

– Types of fabrics include Chenille, Cotton Duck, Crypton, Damask, Embroider…

7. SMS Auto Fabrics – Classic Auto Interiors

Domain: smsautofabrics.com

Registered: 2000 (25 years)

Introduction: SMS Auto Fabrics offers a wide selection of classic auto interiors including cloth, vinyl, leather, door panels, headliners, vinyl tops, and carpets for American cars from the 1930s to the 1990s. Featured products include plaid fabrics for various Chevrolet models from 1972 and 1973, as well as door panels for models such as the 1968 Dodge Polara Convertible, 1970 Chevrolet Malibu Sport Coupe, and…

8. Calico Corners – Upholstery Fabrics

Domain: calicocorners.com

Registered: 1995 (30 years)

Introduction: Upholstery Fabric | Upholstery Weight Fabrics | Available online & in stores! Patterns include jacquard woven brocades, damasks, liserés, tapestries, dobbies, plaids, stripes, tweeds, and tissue-pick motifs. Some fabrics are light enough for window treatments and slipcovers. New Arrivals, Designer Luxe Performance, Color, Pattern Swatches, and Clearance options available. Prices range from $24.74 …

Strategic Sourcing Conclusion and Outlook for seat upholstery fabric

As we conclude our comprehensive guide on seat upholstery fabric, it’s evident that strategic sourcing plays a pivotal role in ensuring quality, durability, and aesthetic appeal in upholstery materials. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the diverse fabric options—from stain-resistant synthetics to luxurious natural fibers—can significantly enhance product offerings and customer satisfaction.

Investing in high-performance upholstery fabrics can yield substantial long-term benefits, including reduced maintenance costs and improved durability, which are crucial for high-traffic environments. Moreover, aligning with reputable suppliers who prioritize sustainability and ethical manufacturing practices can strengthen brand reputation and appeal to increasingly conscientious consumers.

Looking ahead, the upholstery fabric market is poised for growth, driven by innovations in textile technology and evolving consumer preferences. As you strategize your sourcing decisions, consider leveraging industry trends and supplier capabilities to stay ahead of the competition. Engage with trusted partners, explore new materials, and prioritize quality to elevate your product lines. Together, let’s shape the future of upholstery fabric sourcing for a more sustainable and stylish tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.