Introduction: Navigating the Global Market for blue leather fabric

In today’s competitive landscape, sourcing high-quality blue leather fabric can present significant challenges for international B2B buyers. Whether you’re seeking durable upholstery for furniture, automotive applications, or innovative leathercraft solutions, understanding the intricacies of the global market is crucial. This guide aims to equip businesses across Africa, South America, the Middle East, and Europe—regions known for their vibrant manufacturing and design sectors, such as Brazil and Saudi Arabia—with the insights needed to make informed purchasing decisions.

Our comprehensive exploration delves into various types of blue leather fabrics, including genuine leather and faux alternatives, highlighting their unique characteristics and applications. We will discuss essential factors such as supplier vetting, ensuring quality and reliability, as well as cost considerations that can affect your bottom line. Additionally, this guide provides practical tips on ordering, including sample requests and volume discounts, to help streamline your procurement process.

By empowering B2B buyers with actionable insights and knowledge about the diverse landscape of blue leather fabrics, this guide seeks to foster strategic partnerships and enhance your supply chain efficiency. Navigate the complexities of sourcing with confidence and discover how the right materials can elevate your projects to new heights.

Table Of Contents

- Top 6 Blue Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for blue leather fabric

- Understanding blue leather fabric Types and Variations

- Key Industrial Applications of blue leather fabric

- 3 Common User Pain Points for ‘blue leather fabric’ & Their Solutions

- Strategic Material Selection Guide for blue leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for blue leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘blue leather fabric’

- Comprehensive Cost and Pricing Analysis for blue leather fabric Sourcing

- Alternatives Analysis: Comparing blue leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for blue leather fabric

- Navigating Market Dynamics and Sourcing Trends in the blue leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of blue leather fabric

- Strategic Sourcing Conclusion and Outlook for blue leather fabric

- Important Disclaimer & Terms of Use

Understanding blue leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Blue Leather | Made from cowhide; durable and high-quality finish | Furniture upholstery, automotive interiors | Pros: Premium feel, longevity. Cons: Higher cost, requires maintenance. |

| Blue Faux Leather | Synthetic alternative; often more affordable | Budget-friendly furniture, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Less durable than genuine leather. |

| Performance Blue Leather | Engineered for high wear; stain and water resistant | Hospitality, commercial upholstery, automotive | Pros: Exceptional durability, versatile use. Cons: May have a plastic feel. |

| Distressed Blue Leather | Vintage look with a worn texture | Residential furniture, boutique shops | Pros: Unique aesthetic, character. Cons: May show wear faster, not ideal for formal settings. |

| Blue Suede Leather | Soft, plush texture; typically less durable | Fashion items, high-end upholstery | Pros: Luxurious feel, visually appealing. Cons: More susceptible to stains and damage. |

What Are the Characteristics of Genuine Blue Leather?

Genuine blue leather is crafted from high-quality cowhide, offering a luxurious finish that is both durable and visually appealing. This type of leather is often used in high-end furniture and automotive interiors, making it a preferred choice for B2B buyers looking for premium materials. When purchasing, consider the leather’s source and tanning process, as these factors greatly influence quality and longevity. While it comes at a higher price point, the investment often pays off in terms of durability and aesthetic appeal.

How Does Blue Faux Leather Compare to Genuine Options?

Blue faux leather is a synthetic alternative that provides an affordable option for businesses looking to furnish spaces without the hefty price tag of genuine leather. It is commonly used in budget-friendly furniture and fashion accessories, making it suitable for various applications. Buyers should be aware that while faux leather is easier to clean and maintain, it typically lacks the durability and longevity of genuine leather. This option is ideal for those prioritizing cost-effectiveness over premium quality.

Why Choose Performance Blue Leather for Commercial Uses?

Performance blue leather is designed to withstand high levels of wear and tear, making it an excellent choice for commercial applications such as hospitality and automotive upholstery. This engineered material is often stain and water-resistant, ensuring that it maintains its appearance over time. B2B buyers should consider the specific performance ratings, such as Wyzenbeek rub counts, when selecting fabrics for high-traffic environments. While it may have a more synthetic feel compared to natural leather, its durability makes it a practical investment.

What Makes Distressed Blue Leather Unique?

Distressed blue leather offers a distinctive vintage aesthetic, characterized by its worn texture and unique color variations. This type of leather is often used in residential furniture and boutique shops to create a rustic or retro vibe. Buyers should note that while distressed leather adds character, it may show wear more quickly than other types. It’s essential to consider the intended use and setting when opting for this material, as it may not suit formal environments.

How Does Blue Suede Leather Fit into the Market?

Blue suede leather is known for its soft, plush texture, providing a luxurious feel that is often sought after in fashion items and high-end upholstery. While it offers a visually appealing option, it is typically less durable than other types of leather, making it more susceptible to stains and damage. B2B buyers should weigh the aesthetic benefits against the practicality of maintenance and longevity when considering suede for their projects. This material is best suited for applications where luxury and appearance take precedence over durability.

Key Industrial Applications of blue leather fabric

| Industry/Sector | Specific Application of blue leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Enhances aesthetic appeal and durability of furniture | Quality assurance, color consistency, and material sourcing |

| Automotive | Interior car upholstery | Provides luxury feel and longevity in vehicle interiors | Compliance with safety standards and resistance to wear |

| Fashion and Apparel | Jackets, bags, and accessories | Offers a stylish and durable option for high-end products | Ethical sourcing and trend alignment |

| Hospitality | Seating in hotels and restaurants | Creates a welcoming atmosphere while ensuring durability | Bulk purchasing options and customization capabilities |

| Marine Industry | Boat interiors and upholstery | Water-resistant and durable, ideal for marine environments | UV resistance and compatibility with marine standards |

How is Blue Leather Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, blue leather fabric is predominantly used for upholstery on sofas and chairs. Its rich color and texture enhance the aesthetic appeal of furniture pieces while providing significant durability. B2B buyers in this industry must consider quality assurance and consistency in color, as variations can affect the final product’s marketability. Additionally, sourcing from reputable suppliers ensures the leather meets the necessary standards for comfort and longevity.

What Role Does Blue Leather Fabric Play in Automotive Interiors?

In the automotive industry, blue leather fabric is utilized for interior car upholstery, including seats and door panels. The fabric not only imparts a luxurious feel but also withstands the rigors of daily use, making it ideal for vehicles. International buyers, particularly from regions like the Middle East and Europe, should prioritize suppliers who comply with safety standards and offer materials resistant to wear and tear. This ensures that the upholstery maintains its appearance and functionality over time.

How is Blue Leather Fabric Applied in Fashion and Apparel?

The fashion and apparel industry leverages blue leather fabric for creating stylish jackets, bags, and accessories. This fabric provides a sophisticated look while ensuring durability, making it a favorite among high-end brands. B2B buyers should focus on ethical sourcing practices to align with consumer preferences for sustainability. Additionally, keeping up with fashion trends is crucial to ensure that the products resonate with the target market.

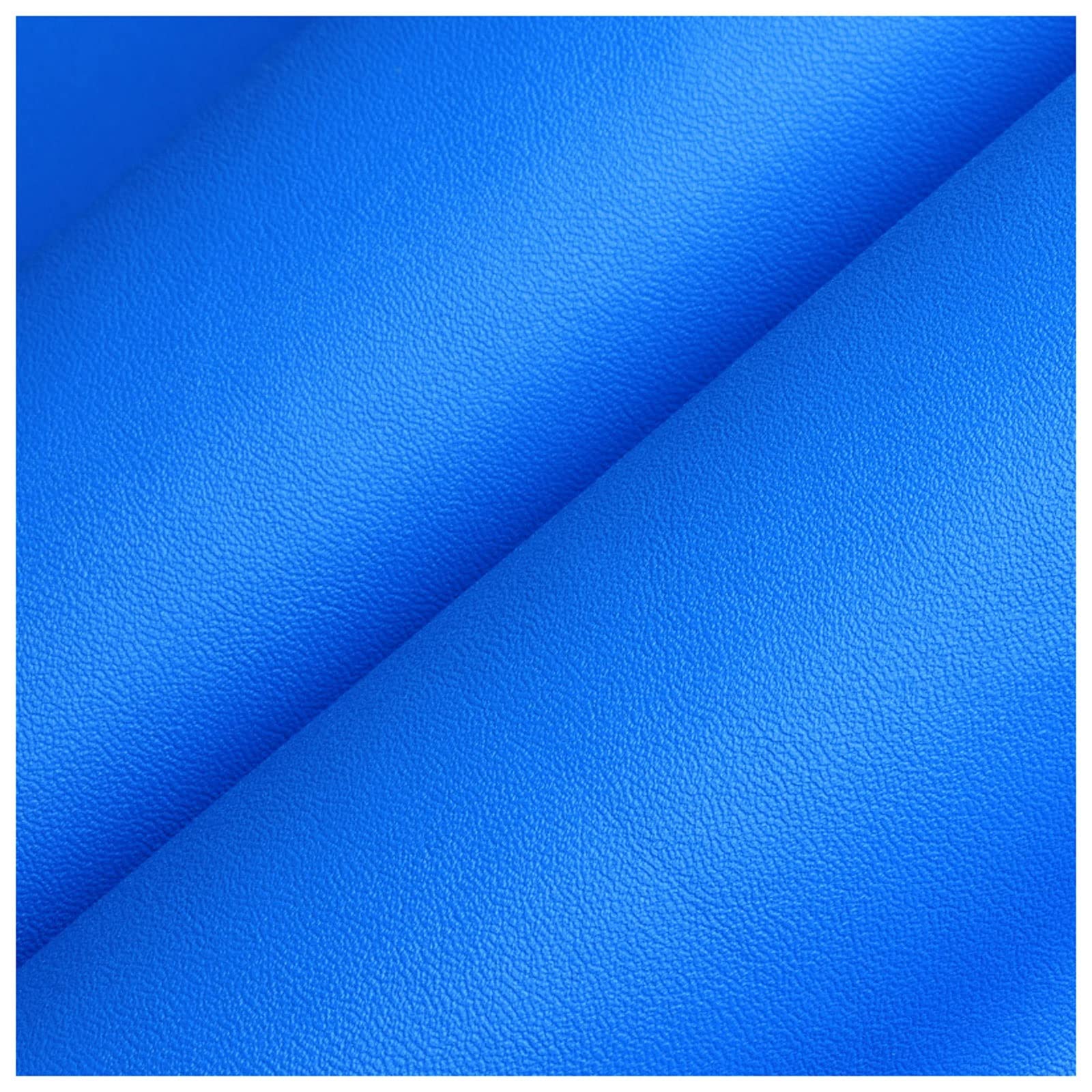

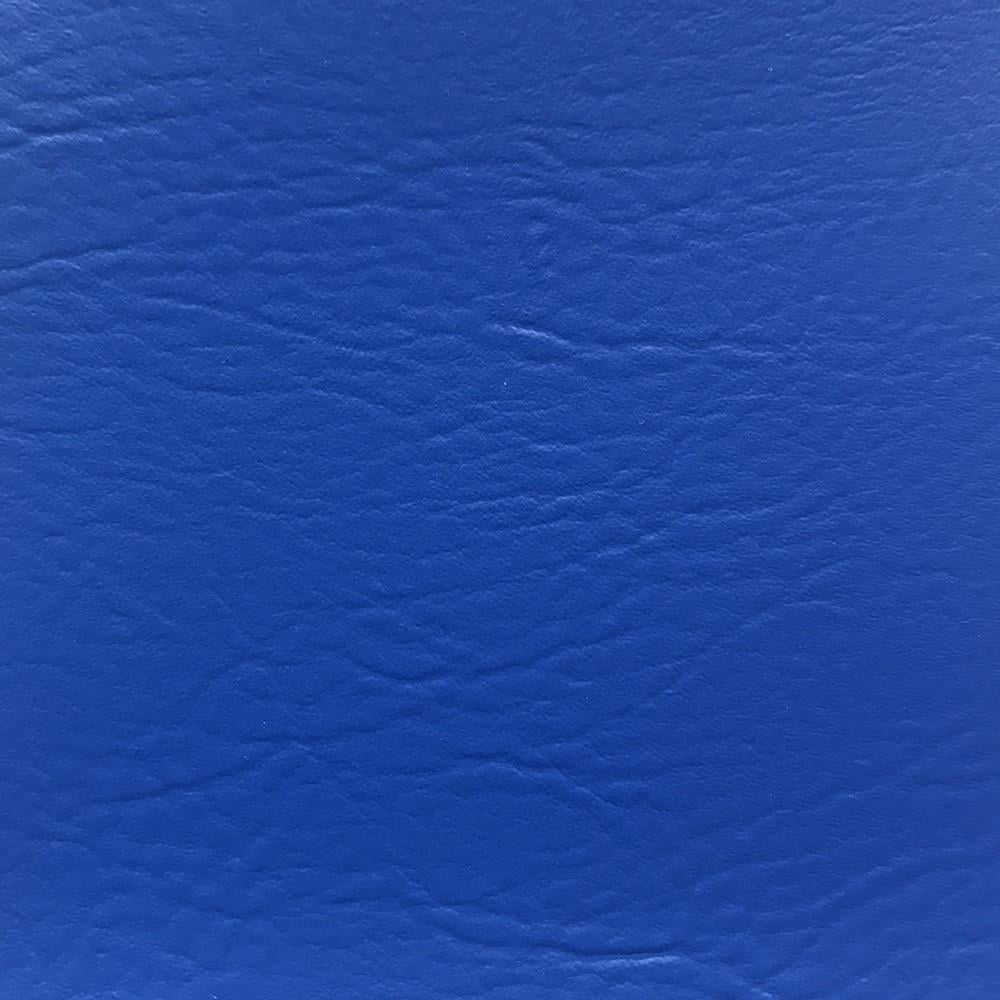

Illustrative image related to blue leather fabric

Why is Blue Leather Fabric Important in the Hospitality Sector?

In hospitality, blue leather fabric is commonly used for seating in hotels and restaurants, contributing to a welcoming and upscale atmosphere. The durability of the fabric ensures that it can withstand heavy use, maintaining its appearance over time. Buyers in this sector should consider bulk purchasing options and the ability to customize colors and textures to fit specific design themes. This flexibility can enhance the overall guest experience and brand image.

What are the Benefits of Blue Leather Fabric in the Marine Industry?

The marine industry utilizes blue leather fabric for boat interiors and upholstery due to its water-resistant properties and durability. This fabric is specifically designed to withstand harsh marine environments, making it an ideal choice for boat manufacturers. Buyers should ensure that the fabric meets UV resistance standards and is compatible with marine upholstery requirements. This ensures longevity and maintains the aesthetic appeal of the boat interiors.

3 Common User Pain Points for ‘blue leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Blue Leather Fabric for Diverse Applications

The Problem:

B2B buyers often face challenges when sourcing blue leather fabric that meets specific quality and application requirements. Whether for upholstery in luxury vehicles, high-end furniture, or fashion accessories, finding a reliable supplier that provides consistent quality can be daunting. Many buyers are concerned about the variability in texture, durability, and color consistency, which are critical factors in ensuring that the final product meets customer expectations and industry standards.

The Solution:

To overcome these sourcing challenges, buyers should establish relationships with reputable suppliers who offer comprehensive product specifications and samples. When approaching potential vendors, ask for detailed information regarding the leather’s grade, origin, and treatment processes. Requesting samples before placing larger orders can help ensure that the leather meets your standards for color and texture. Additionally, consider suppliers that offer transparent communication and a return policy for unsatisfactory products. This proactive approach minimizes the risk of receiving subpar materials and fosters a long-term partnership built on trust and quality assurance.

Illustrative image related to blue leather fabric

Scenario 2: Managing Inventory of Blue Leather Fabric Efficiently

The Problem:

Inventory management is a significant concern for B2B buyers dealing with blue leather fabric, especially when working with various suppliers and product lines. Fluctuations in demand, coupled with the unique sizing and bulk purchasing requirements of leather hides, can lead to excess stock or shortages. This can ultimately affect production schedules and customer satisfaction, resulting in lost sales opportunities.

The Solution:

Implementing a robust inventory management system tailored for leather products can streamline operations and improve forecasting accuracy. Utilize software that tracks inventory levels in real-time, allowing for better visibility into stock and helping to predict future demand based on sales trends. Additionally, consider establishing a minimum order quantity with suppliers to maintain a steady flow of materials while avoiding overstock. Collaborating closely with your suppliers to understand lead times and potential supply chain disruptions will also enable you to make informed purchasing decisions, ensuring that you have adequate stock on hand to meet customer demands without incurring excess inventory costs.

Scenario 3: Ensuring Compliance and Sustainability in Blue Leather Fabric Sourcing

The Problem:

As global awareness around sustainability increases, B2B buyers are often faced with the challenge of ensuring that their blue leather fabric sourcing aligns with environmental and ethical standards. Concerns about animal welfare, environmental impact, and compliance with international regulations can complicate the purchasing process, especially for companies looking to enhance their corporate social responsibility (CSR) profiles.

The Solution:

To navigate these concerns, buyers should prioritize sourcing from suppliers who demonstrate a commitment to sustainable practices and ethical sourcing. Look for certifications such as the Leather Working Group (LWG) certification, which indicates adherence to environmental standards in the leather production process. Additionally, engage in dialogue with suppliers about their sourcing practices and request documentation to verify their claims. Establishing a clear set of ethical sourcing guidelines within your organization can also aid in evaluating potential suppliers, ensuring that all purchased materials not only meet quality standards but also align with your company’s values and sustainability goals. This approach not only mitigates risks but also enhances your brand reputation in an increasingly conscious marketplace.

Strategic Material Selection Guide for blue leather fabric

What Are the Key Properties of Genuine Blue Leather Fabric?

Genuine blue leather fabric, primarily sourced from cowhide, is renowned for its durability and aesthetic appeal. Key properties include high tensile strength, which allows it to withstand significant wear and tear, making it suitable for various applications such as upholstery, automotive interiors, and fashion accessories. Its natural grain texture adds a unique character to each hide, while its ability to be dyed in vibrant blue shades enhances its versatility. However, genuine leather requires careful maintenance to preserve its appearance, especially in humid climates, which can lead to mold and mildew if not properly treated.

Illustrative image related to blue leather fabric

How Does Faux Blue Leather Compare to Genuine Leather?

Faux blue leather, often made from polyurethane or PVC, offers a cost-effective alternative to genuine leather. Key properties include water resistance and ease of cleaning, making it ideal for environments where spills and stains are common. While faux leather is generally less durable than genuine leather, advancements in manufacturing have led to products that can withstand moderate use. The primary advantage is its lower price point and ethical appeal, especially in markets sensitive to animal welfare. However, faux leather may not provide the same luxurious feel or breathability as genuine leather, which could impact its suitability for high-end applications.

What Are the Advantages of Performance Blue Leather Fabrics?

Performance blue leather fabrics, such as those treated for stain resistance and durability, are engineered to meet high standards of wear and tear. These materials typically exceed 2 million double rubs on the Wyzenbeek scale, making them suitable for commercial and hospitality settings where heavy use is anticipated. The key advantage lies in their ability to combine aesthetic appeal with functional performance, ensuring long-lasting use without compromising on style. However, the manufacturing complexity can lead to higher costs, which may be a consideration for budget-conscious buyers. Additionally, performance fabrics may not be as eco-friendly as their natural counterparts, which could influence purchasing decisions in environmentally conscious markets.

What Should International Buyers Consider When Sourcing Blue Leather Fabrics?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider various factors when sourcing blue leather fabrics. Compliance with local regulations and standards, such as ASTM, DIN, or JIS, is crucial to ensure product safety and quality. Additionally, buyers should be aware of regional preferences for material types, with some markets favoring sustainable options over synthetic alternatives. Logistics and shipping costs can also vary significantly depending on the origin of the materials, impacting overall pricing. Understanding these dynamics can help buyers make informed decisions that align with their market needs.

Illustrative image related to blue leather fabric

Summary Table of Blue Leather Fabric Materials

| المواد | Typical Use Case for blue leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Upholstery, automotive interiors, fashion accessories | High durability and aesthetic appeal | Requires maintenance; sensitive to humidity | عالية |

| جلد صناعي | Commercial upholstery, fashion items, casual furniture | Cost-effective and easy to clean | Less durable; may lack luxury feel | منخفضة |

| Performance Leather Fabrics | Hospitality, commercial furniture, high-traffic areas | Excellent durability and stain resistance | Higher manufacturing complexity; costlier | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various types of blue leather fabrics available, helping them make informed purchasing decisions that align with their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for blue leather fabric

What Are the Main Stages in the Manufacturing Process of Blue Leather Fabric?

The manufacturing process for blue leather fabric involves several critical stages, each contributing to the quality and durability of the final product. Understanding these stages can help B2B buyers make informed decisions when sourcing leather products for their businesses.

Material Preparation: What Goes Into Making Blue Leather?

The journey of blue leather fabric begins with material preparation. Typically, cowhides are the primary raw material used, and they must be sourced from reputable suppliers to ensure quality. The hides undergo a thorough cleaning process to remove impurities and residues. This step is crucial because any defects in the hide can affect the final product’s appearance and performance.

After cleaning, the hides are dyed to achieve the desired blue hue. Various dyeing techniques, such as aniline and semi-aniline dyeing, are employed to enhance color penetration while maintaining the natural texture of the leather. The choice of dyeing technique can significantly influence the leather’s aesthetic and functional properties.

Illustrative image related to blue leather fabric

Forming: How Is Blue Leather Fabric Shaped?

Once the hides are dyed, they undergo the forming process, where they are cut into specific shapes and sizes based on the intended application, whether for upholstery, automotive interiors, or fashion. Advanced cutting technologies, such as laser cutting, are often used to ensure precision and minimize waste.

During this stage, manufacturers may also apply additional treatments, such as waterproofing or fire-resistance, depending on the end-use requirements. These treatments are vital for enhancing the leather’s longevity and functionality, especially in demanding environments.

Assembly: What Techniques Are Used in Crafting Blue Leather Products?

The assembly stage involves stitching or bonding the cut pieces of leather together to create the final product. Skilled artisans often handle this process, employing techniques such as double-stitching for added durability. Automated sewing machines may also be utilized to increase efficiency and consistency.

Illustrative image related to blue leather fabric

Quality control measures are essential during assembly. Manufacturers typically perform checks at this stage to ensure that all components fit correctly and meet design specifications. Any defective pieces are discarded or reworked to maintain high standards.

Finishing: How Is the Final Touch Applied to Blue Leather?

The finishing stage is where blue leather fabric truly comes to life. This process includes applying protective coatings to enhance the leather’s resistance to stains, scratches, and fading. Various finishes, such as matte, glossy, or textured, can be applied to achieve the desired look and feel.

Additionally, manufacturers may conduct final inspections to ensure that the leather meets all quality criteria, including color consistency and surface quality. This stage is critical for ensuring that the product is ready for market and aligns with customer expectations.

Illustrative image related to blue leather fabric

What Quality Assurance Measures Are in Place for Blue Leather Fabric?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that blue leather fabric meets both international standards and specific industry requirements. For B2B buyers, understanding the QA measures in place can help mitigate risks associated with product sourcing.

What International Standards Should Buyers Consider?

One of the most recognized international standards for quality management is ISO 9001. Compliance with this standard indicates that the manufacturer has established a quality management system that consistently meets customer and regulatory requirements. Buyers should inquire whether their suppliers hold ISO 9001 certification, as it reflects a commitment to quality and continuous improvement.

In addition to ISO 9001, specific industry standards may apply, such as CE marking for products sold within the European Union. This certification ensures that the leather products meet health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to the QA process, ensuring that defects are identified and addressed at various stages of production. Common checkpoints include:

Illustrative image related to blue leather fabric

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials, such as hides and dyes, before they enter the production process. Suppliers should provide certificates of authenticity and quality for their materials.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves regular inspections to monitor the production flow and ensure adherence to quality standards. This stage allows for immediate corrective actions if any discrepancies arise.

-

Final Quality Control (FQC): The final inspection occurs before the products are shipped to customers. This step verifies that the finished products meet all specifications and quality criteria, ensuring that they are ready for market release.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are some actionable steps to consider:

-

Conduct Supplier Audits: Regular audits can help assess compliance with quality standards and identify areas for improvement. Buyers should develop an audit checklist that aligns with their specific requirements.

-

Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC. These reports can offer insights into the supplier’s commitment to maintaining high-quality standards.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. This step is particularly beneficial for buyers who may not have the resources to conduct audits themselves.

What Are the Nuances of Quality Control for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing blue leather fabric. Different regions may have varying quality expectations and regulatory requirements, which can impact sourcing decisions.

For instance, buyers in Europe may prioritize compliance with EU regulations regarding environmental sustainability and chemical safety, while buyers in the Middle East may focus on durability and performance in high-temperature environments. Understanding these regional differences can enhance negotiation strategies and supplier relationships.

In summary, the manufacturing processes and quality assurance measures for blue leather fabric are intricate and multifaceted. By understanding these aspects, international B2B buyers can make informed decisions that align with their quality expectations and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blue leather fabric’

In the competitive landscape of B2B sourcing, procuring blue leather fabric requires a systematic approach to ensure quality, compliance, and cost-effectiveness. This practical checklist is designed to guide international buyers through the essential steps of sourcing blue leather fabric, whether for upholstery, automotive applications, or fashion.

Step 1: Define Your Technical Specifications

Establish clear specifications for your blue leather fabric needs, including material type (genuine or faux), thickness, texture, and intended use. This is crucial as it directly influences both the performance and aesthetic of the final product. Be specific about factors such as:

– Durability Requirements: Consider the expected wear and tear for your application.

– Color Accuracy: Ensure the shade of blue aligns with your brand standards.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify reputable suppliers with a proven track record in blue leather fabric. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential suppliers. Look for:

– Supplier Certifications: Verify if they meet industry standards such as ISO or other relevant certifications.

– Market Reputation: Read reviews and testimonials to gauge customer satisfaction.

Step 3: Request Samples

Before making any purchase, request samples of the blue leather fabric from shortlisted suppliers. This step is vital for assessing the quality, texture, and color accuracy. When evaluating samples:

– Compare Physical Attributes: Check for consistency in grain, color, and finish.

– Conduct Durability Tests: Perform simple tests to assess scratch resistance and overall sturdiness.

Illustrative image related to blue leather fabric

Step 4: Evaluate Pricing Structures

Gather quotes from multiple suppliers and compare pricing models. Understanding the pricing structure is essential for budget management and cost control. Be mindful of:

– Minimum Order Quantities (MOQs): Some suppliers may impose MOQs that could affect your total costs.

– Shipping and Import Fees: Factor in any additional costs associated with logistics, especially for international orders.

Step 5: Verify Compliance with Regulations

Ensure that the blue leather fabric complies with the relevant safety and environmental regulations in your target market. This is particularly important when sourcing from different regions. Check for:

– Chemical Safety Standards: Verify that the fabric meets regulations such as REACH in Europe or similar standards elsewhere.

– Sustainability Practices: Inquire about the sourcing practices to ensure ethical procurement.

Step 6: Assess Delivery and Support Services

Evaluate the supplier’s ability to meet your delivery timelines and their customer service capabilities. Effective communication and support can significantly impact your sourcing experience. Consider:

– Lead Times: Confirm the expected production and shipping timelines.

– After-Sales Support: Understand the supplier’s policies on returns, exchanges, and issue resolution.

Step 7: Finalize Your Order and Document Everything

Once you have selected a supplier, finalize your order with a clear contract that outlines all terms and conditions. Proper documentation protects both parties and sets clear expectations. Ensure to include:

– Payment Terms: Specify payment methods and timelines.

– Quality Assurance Clauses: Include provisions for quality checks and remedies for defects.

Following this checklist will streamline your procurement process for blue leather fabric, reducing risk and ensuring that you secure the best materials for your business needs.

Comprehensive Cost and Pricing Analysis for blue leather fabric Sourcing

Understanding the cost structure and pricing dynamics of blue leather fabric sourcing is essential for B2B buyers, especially when navigating international markets. This analysis delves into the critical components that shape costs and prices, offering actionable insights for optimizing procurement strategies.

What Are the Key Cost Components in Blue Leather Fabric Sourcing?

The cost structure for blue leather fabric can be broken down into several essential components:

-

Materials: The primary cost driver is the quality of leather or faux leather used. Genuine leather typically commands a higher price due to its durability and aesthetic appeal. In contrast, faux leather offers a more budget-friendly alternative, but the quality can vary significantly based on the manufacturing process and material composition.

-

Labor: Labor costs encompass the wages paid to workers involved in cutting, stitching, and finishing the leather. Countries with lower labor costs can provide a competitive edge, but this may come at the expense of quality and craftsmanship.

-

Manufacturing Overhead: This includes costs associated with the facility, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, impacting the final pricing.

-

Tooling: For customized orders, tooling costs can be significant. This includes the creation of molds or patterns specific to a buyer’s requirements, which can add to the initial investment.

-

Quality Control (QC): Implementing stringent QC processes ensures that the leather meets the desired specifications and quality standards. While this adds to costs, it can prevent future issues related to returns or replacements.

-

Logistics: Transportation and shipping costs are crucial, especially for international buyers. Factors such as distance, shipping method, and customs duties can substantially affect the overall cost.

-

Margin: Suppliers typically include a profit margin that varies based on market demand, competition, and the perceived value of the product. Understanding the margin can help buyers gauge the reasonableness of pricing.

How Do Price Influencers Affect Blue Leather Fabric Costs?

Several factors can influence the pricing of blue leather fabric:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to lower per-unit costs. Negotiating for better pricing based on larger orders can yield significant savings.

-

Specifications and Customization: Custom designs or specific color requirements may increase costs due to additional labor and tooling. Buyers should weigh the need for customization against potential cost increases.

-

Material Quality and Certifications: Fabrics that come with certifications for sustainability or performance (e.g., fire resistance) may incur higher costs but can enhance product value.

-

Supplier Factors: The reputation, reliability, and location of suppliers can affect pricing. Establishing long-term relationships with trusted suppliers can lead to better pricing and terms.

-

Incoterms: Understanding shipping terms is crucial for calculating total costs. Different Incoterms dictate who bears the shipping costs and risks, impacting the overall pricing strategy.

What Are Effective Buyer Tips for Navigating Blue Leather Fabric Sourcing?

B2B buyers should consider the following strategies for effective negotiation and cost management:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially on larger orders. Suppliers may be willing to offer discounts for guaranteed business or prompt payment.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and potential waste. Higher-quality materials may have a higher upfront cost but can save money in the long run.

-

Understand Pricing Nuances for International Markets: Familiarize yourself with regional pricing trends, tariffs, and trade regulations specific to countries like Brazil, Saudi Arabia, and others in Africa and Europe. This knowledge can help in making informed purchasing decisions.

-

Request Samples: Before finalizing large orders, request samples to assess quality. This step can prevent costly mistakes and ensure that the product meets expectations.

-

Stay Informed on Market Trends: Regularly monitor market conditions, such as fluctuations in raw material prices or changes in consumer demand. Being informed can help buyers anticipate price changes and adjust their sourcing strategies accordingly.

By comprehensively understanding the cost structure and pricing influences associated with blue leather fabric, international B2B buyers can make more strategic purchasing decisions, optimize their supply chains, and ultimately enhance their product offerings.

Illustrative image related to blue leather fabric

Alternatives Analysis: Comparing blue leather fabric With Other Solutions

In the competitive landscape of upholstery materials, international B2B buyers often seek alternatives to blue leather fabric that can deliver similar aesthetic appeal and functionality. Understanding these alternatives is crucial for making informed procurement decisions that align with budgetary constraints and project requirements. Below, we compare blue leather fabric with two viable alternatives: blue faux leather and performance-grade upholstery fabric.

| Comparison Aspect | Blue Leather Fabric | Blue Faux Leather | Performance-Grade Upholstery Fabric |

|---|---|---|---|

| Performance | High durability, natural look, breathability | Good durability, less breathable, synthetic feel | Excellent durability, often stain and water-resistant |

| Cost | Higher price point, varies by hide size | Generally lower cost, priced per yard or roll | Mid-range pricing, offers volume discounts |

| Ease of Implementation | Requires specific tools for cutting and sewing | Easy to cut and sew, lightweight | May require specialized equipment for heavy-duty applications |

| Maintenance | Requires conditioning and special cleaners | Easy to clean with water-based solutions | Low maintenance, typically machine washable |

| Best Use Case | Luxury furniture, automotive interiors | Budget-friendly furniture, decorative accents | High-traffic areas, commercial upholstery, pet-friendly applications |

What Are the Benefits and Drawbacks of Blue Faux Leather?

Blue faux leather is a synthetic alternative that mimics the look and feel of real leather without the associated costs. One of its significant advantages is affordability, making it an attractive option for budget-conscious projects. Additionally, faux leather is easy to clean and maintain, requiring only a damp cloth for routine upkeep. However, it generally lacks the breathability and durability of genuine leather, which can lead to quicker wear and a less luxurious appearance over time. It is best suited for decorative pieces or furniture in lower-traffic environments.

How Does Performance-Grade Upholstery Fabric Compare?

Performance-grade upholstery fabric, such as those made with vinyl or polyurethane, offers excellent durability and is often designed to withstand high wear and tear. Many of these fabrics are stain-resistant and easy to clean, making them ideal for commercial settings or households with pets. While they can be priced competitively with blue leather fabric, their look may not convey the same luxury as real leather. Buyers might find this option appealing for high-traffic areas or environments where durability is paramount, but they should consider the aesthetic trade-offs involved.

Conclusion: How Should B2B Buyers Choose the Right Upholstery Solution?

When selecting the right upholstery material, B2B buyers should assess their specific needs, including budget, expected wear and tear, and desired aesthetics. If a luxurious appearance and natural feel are paramount, blue leather fabric may be the best choice despite its higher cost. Conversely, for projects requiring cost-effectiveness and ease of maintenance, blue faux leather or performance-grade upholstery fabric could serve as practical alternatives. Careful evaluation of these factors will empower buyers to make decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for blue leather fabric

What Are the Key Technical Properties of Blue Leather Fabric?

When evaluating blue leather fabric for B2B procurement, several technical properties are crucial. Understanding these specifications can help buyers make informed decisions that align with their project needs.

1. Material Grade

The material grade refers to the quality classification of the leather, which can range from full-grain to corrected grain. Full-grain leather is the highest quality, preserving the natural texture and durability, making it ideal for high-end applications. Conversely, corrected grain leather has a more uniform appearance but may lack some of the unique characteristics of natural leather. Buyers should consider the material grade based on the intended use, whether for luxury upholstery or more utilitarian applications.

2. Tolerance

Tolerance indicates the allowable variation in the thickness and dimensions of the leather hide. For instance, a tolerance of ±0.5 mm on thickness ensures that the leather can be processed consistently in manufacturing. Understanding tolerance is vital for ensuring the leather fits properly in specific applications, such as automotive interiors or furniture upholstery. It directly impacts the performance and aesthetics of the final product.

3. Durability Rating

The durability rating often involves testing the leather against the Wyzenbeek test, which measures abrasion resistance. A high durability rating, such as exceeding 50,000 double rubs, indicates that the leather can withstand significant wear and tear, making it suitable for high-traffic areas. This property is particularly important for buyers in sectors like hospitality or automotive, where longevity is a key concern.

4. Color Fastness

Color fastness refers to the leather’s ability to retain its color when exposed to light, moisture, and various chemicals. This property is critical for ensuring the blue leather fabric maintains its appearance over time. Buyers should look for fabrics that have passed rigorous color fastness tests, especially for applications in outdoor furniture or automotive interiors where exposure to the elements is common.

5. Weight

The weight of blue leather fabric, typically measured in ounces per square yard, influences its application. Heavier leather may be more suitable for upholstery, while lighter variants could be used for accessories or garments. Understanding the weight helps buyers select the right type for their projects, ensuring functionality and aesthetics are both met.

What Trade Terminology Should B2B Buyers Know About Blue Leather Fabric?

Familiarity with industry-specific terminology can streamline communication and negotiation processes in B2B transactions for blue leather fabric.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of leather, an OEM may produce leather components for automotive or furniture manufacturers. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of a product that a supplier is willing to sell. For blue leather fabric, suppliers may set an MOQ to cover production costs. Buyers should be aware of MOQs to plan their purchasing strategy effectively, ensuring they meet their project requirements without overcommitting.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of leather fabric. This process allows buyers to compare prices and terms from different vendors. Crafting a detailed RFQ can lead to better pricing and conditions, ultimately benefiting the procurement process.

4. Incoterms

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers understand shipping costs and liabilities associated with importing blue leather fabric.

Illustrative image related to blue leather fabric

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. In the leather industry, this can vary based on the supplier’s inventory and production capabilities. Understanding lead times is essential for project planning, ensuring that materials arrive when needed to avoid delays.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing blue leather fabric more effectively, ensuring they make informed and strategic purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the blue leather fabric Sector

What Are the Key Trends Driving the Blue Leather Fabric Market?

The blue leather fabric market is experiencing a dynamic shift driven by several global factors. One significant driver is the rising demand for customization in upholstery materials across various sectors, including automotive, furniture, and fashion. International buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for unique textures and colors, with blue leather becoming a preferred choice for its versatility and aesthetic appeal.

Emerging technologies are also influencing sourcing trends. Digital platforms and e-commerce have streamlined the procurement process, allowing buyers to access a broader range of suppliers and compare prices and product specifications quickly. Additionally, innovations in synthetic alternatives, such as faux leather, offer cost-effective solutions while catering to the growing trend of sustainability.

Market dynamics are also shaped by regional preferences and economic conditions. For instance, in Brazil and Saudi Arabia, the booming real estate and automotive industries are driving demand for high-quality upholstery materials. In Europe, there’s a noticeable shift towards performance-grade fabrics that combine durability with style, prompting suppliers to enhance their offerings in blue leather fabrics that meet these standards.

How Is Sustainability and Ethical Sourcing Impacting the Blue Leather Fabric Industry?

Sustainability is becoming increasingly critical in the sourcing of blue leather fabric. The environmental impact of leather production has raised concerns among consumers and businesses alike, prompting a shift towards more sustainable practices. B2B buyers are now prioritizing suppliers that demonstrate a commitment to ethical sourcing, ensuring that their materials are produced with minimal environmental harm.

Ethical supply chains are essential for fostering transparency and trust. Many buyers now seek out suppliers who can provide certifications that attest to the sustainable practices employed in the production of blue leather. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification are becoming benchmarks for responsible sourcing. Furthermore, the trend towards using eco-friendly dyes and processes is gaining traction, appealing to a market that values environmental responsibility.

Investing in sustainable blue leather fabric not only helps companies meet regulatory demands but also enhances their brand image among environmentally conscious consumers. This shift in priorities means that B2B buyers must stay informed about the latest sustainable materials and practices to make responsible purchasing decisions.

What Is the Historical Context of Blue Leather Fabric in B2B Markets?

The evolution of blue leather fabric can be traced back to traditional leatherworking techniques, where artisans would dye leather in various shades, including blue, to create unique products. Historically, blue leather was often associated with luxury and craftsmanship, used in high-end fashion and bespoke furniture.

In the 20th century, the introduction of synthetic materials revolutionized the industry, making blue leather more accessible to a broader audience. As global trade expanded, so did the availability of diverse blue leather options, catering to various market segments. Today, the blue leather fabric sector is characterized by a blend of traditional craftsmanship and modern production techniques, enabling businesses to meet the diverse needs of international buyers.

Illustrative image related to blue leather fabric

The ongoing evolution of blue leather fabric reflects broader trends in consumer preferences and environmental consciousness, making it a significant component of the global textile and upholstery market. Understanding this historical context can provide B2B buyers with insights into the product’s value and the importance of sourcing responsibly.

Frequently Asked Questions (FAQs) for B2B Buyers of blue leather fabric

-

How do I choose the right type of blue leather fabric for my project?

Choosing the right blue leather fabric depends on the intended use and required durability. For upholstery, consider options with high abrasion resistance, such as performance-grade leather, which can withstand heavy use. If you need a more cost-effective solution, faux leather can provide a stylish alternative. Evaluate factors such as texture, color variation, and the specific application—be it automotive, residential, or commercial—to ensure the selected material meets your project needs. -

What factors should I consider when sourcing blue leather fabric internationally?

When sourcing blue leather fabric internationally, consider quality, supplier reliability, and compliance with local regulations. Check if the supplier provides certifications for material quality and environmental sustainability. Also, assess shipping logistics, including customs regulations in your country. Building a relationship with your supplier can facilitate smoother transactions and better communication, which is crucial for international deals. -

What are the minimum order quantities (MOQ) for blue leather fabric?

Minimum order quantities (MOQ) for blue leather fabric can vary significantly by supplier. Typically, MOQs range from one hide to several hundred yards, depending on the type of leather and the supplier’s production capabilities. It’s advisable to clarify the MOQ before committing to an order, as some suppliers may offer flexibility for bulk orders or first-time buyers. Understanding these terms can help you manage inventory and costs effectively. -

How can I ensure the quality of blue leather fabric before purchasing?

To ensure quality, request samples from potential suppliers before making a bulk purchase. This allows you to evaluate the fabric’s texture, color accuracy, and durability. Additionally, inquire about the supplier’s quality assurance processes and whether they offer any warranties or guarantees. Look for reviews or testimonials from other buyers to gauge the supplier’s reliability and product quality, which is crucial for maintaining your business’s reputation. -

What payment terms are typically offered by suppliers of blue leather fabric?

Payment terms can vary widely among suppliers, often depending on the order size and buyer-supplier relationship. Common terms include payment in advance, net 30, or even net 60 days, particularly for larger orders. Some suppliers may also accept letters of credit, which provide additional security for both parties. Always clarify payment terms before finalizing an order to avoid misunderstandings that could impact your cash flow. -

What are the logistics considerations for importing blue leather fabric?

Logistics for importing blue leather fabric include understanding shipping methods, lead times, and customs duties. Choose a reliable freight forwarder experienced in handling textiles to ensure smooth transportation. Be aware of import regulations in your country, including tariffs and taxes, which can affect your overall costs. Planning for potential delays and ensuring proper documentation can help streamline the import process. -

Can I customize blue leather fabric for my specific needs?

Many suppliers offer customization options for blue leather fabric, including color matching, embossing, and specific finishes. It’s essential to discuss your requirements upfront to determine if the supplier can accommodate them. Custom orders may come with higher MOQs and longer lead times, so factor this into your project timeline. Ensure that you receive samples of the customized fabric before finalizing the order to confirm it meets your expectations. -

What certifications should I look for when sourcing blue leather fabric?

When sourcing blue leather fabric, look for certifications that indicate quality and sustainability, such as ISO 9001 for quality management and the Global Organic Textile Standard (GOTS) for organic textiles. Additionally, certifications like the Leather Working Group (LWG) can assure you that the leather is sourced ethically and produced with minimal environmental impact. These certifications can enhance your brand’s reputation and meet consumer demand for responsible sourcing.

Top 6 Blue Leather Fabric Manufacturers & Suppliers List

1. Leather Hide Store – Blue Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

مقدمة: Blue Upholstery Leather available at Leather Hide Store. Sold by the hide, not on rolls or sheets. Average size of cowhide is 50 square feet. Widely used for furniture, automotive, and general leathercraft. Closeout items offer exceptional quality at greater savings. Specific blue leather options include: K1147 Teal Surprise, K1153 Rockin Blues, K777 Cool Mint, K1215 Sapphire Blue Shimmer, K1111 I…

2. Naugahyde – Blue Faux Leather Upholstery Vinyl

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

مقدمة: Blue Faux Leather Upholstery Vinyl available from various brands including Naugahyde and Boltaflex. Prices range from $8.95 to $33.95 per yard. Multiple colors and styles available, with stock quantities varying from 5 to 59 yards. Free shipping on orders over $199 with coupon code SHIPFREE. Suitable for automotive, furniture, and marine use.

3. Kovi Fabrics – K8556 Royal Upholstery Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

مقدمة: {“Pattern number”:”K8556 Royal”,”Recommended use”:”Upholstery, Automotive, Contract, Home”,”Warranty”:”Limited lifetime warranty”,”Minimum order”:”1 yard”,”Collection”:”UltraHyde”,”Color”:”Blue”,”Type”:”Performance Grade, Pet Friendly, Stain Resistant”,”Pattern”:”Leather Grain, Plain & Solid”,”Material Contents”:”Face: Vinyl/Polyurethane, Back: Polyester Microsuede, 29oz.”,”Cleaning”:”Water Based …

4. Import – Mitchell Faux Leather Outback Sky Fabric

Domain: fabricmill.com

Registered: 1997 (28 years)

مقدمة: {“name”:”Mitchell Faux Leather Outback Sky Fabric”,”SKU”:”355006″,”manufacturer”:”Import”,”price”:”$24.99″,”fiber_content”:”100% Polyurethane”,”usage”:”This fabric may be used for handbags, furniture, headboards, cornices or wall upholstery.”,”fire_rating”:”California Bulletin 117-2013, Section 1, U.F.A.C. Class 1, NFPA 260, MVSS-302″,”width”:”54 inches”,”durability”:”100000 Double Rubs”,”type_of_…

5. H&T Fabrics – ROYAL BLUE Faux Leather Vinyl Upholstery Fabric

Domain: ebay.com

Registered: 1995 (30 years)

مقدمة: {‘title’: ‘ROYAL BLUE Faux Leather Vinyl Upholstery Fabric (54 in.) Sold By The Yard’, ‘brand’: ‘H&T Fabrics’, ‘condition’: ‘New’, ‘price’: ‘US $24.99 or Best Offer’, ‘quantity_available’: ‘More than 10 available’, ‘shipping_cost’: ‘US $14.58’, ‘location’: ‘New York, NY, United States’, ‘fiber_content’: ‘Synthetic’, ‘length_amount’: ‘By the Yard’, ‘material’: ‘Faux Leather, Vinyl’, ‘width’: “46” …

6. Savvy Swatch – Europatex Neptune Marine Faux Leather Vinyl

Domain: savvyswatch.com

Registered: 2013 (12 years)

مقدمة: Collection: Leather & Vinyl – Color: Blue/Light Blue – Featured Products: 1. Europatex Neptune Marine Faux Leather Vinyl – Sale Price: $47.90 (Save $117.99) 2. J Ennis Challenger 303 Denim Blue Vinyl Fabric – Sale Price: $59.90 (Save $43.90) 3. Sealskin 3333 Imperial Blue Upholstery Fabric by Vision Fabrics – Sale Price: $44.90 (Save $29.50) 4. Sealskin 3 Royal Blue Upholstery Fabric by Vision Fab…

Strategic Sourcing Conclusion and Outlook for blue leather fabric

In navigating the dynamic landscape of blue leather fabric sourcing, B2B buyers must prioritize strategic relationships and informed decision-making. The versatility of blue leather—whether genuine or faux—positions it as a prime choice for various applications, from upscale furniture to automotive interiors. Understanding the nuances of quality, performance ratings, and sustainability can greatly enhance procurement strategies, ensuring alignment with market demands and consumer preferences.

Moreover, leveraging closeout opportunities allows buyers to capitalize on exceptional value without compromising quality. As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, maintaining agility in sourcing practices will be crucial. Establishing connections with reputable suppliers who offer diverse product ranges can facilitate better negotiation terms and more favorable pricing structures.

Looking ahead, the demand for blue leather fabric is set to grow, driven by trends in interior design and fashion. International buyers are encouraged to engage proactively with suppliers, explore new product lines, and consider innovative materials that meet sustainability goals. By adopting a forward-thinking approach, you can position your business to thrive in this vibrant market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.