Introduction: Navigating the Global Market for fabric for shoes

In today’s competitive landscape, sourcing high-quality fabric for shoes poses a significant challenge for international B2B buyers. With a myriad of options ranging from traditional cotton to advanced synthetic blends, understanding the nuances of fabric selection is crucial for creating footwear that meets both aesthetic and functional demands. This comprehensive guide delves into the diverse types of textiles available for shoe manufacturing, their applications, and the vital aspects of supplier vetting, pricing structures, and import regulations.

By equipping buyers from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Vietnam—with actionable insights, this guide empowers them to make informed purchasing decisions. Whether you are exploring eco-friendly materials or cutting-edge technologies in fabric design, our analysis will help you navigate the complexities of the global fabric market effectively.

Additionally, we address key considerations such as thread composition, weave patterns, and surface treatments, ensuring that you have a holistic understanding of the materials at your disposal. With this resource, you will not only enhance your procurement strategy but also foster innovation in your footwear designs, ultimately driving greater value in your offerings to consumers.

Table Of Contents

- Top 7 Fabric For Shoes Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric for shoes

- Understanding fabric for shoes Types and Variations

- Key Industrial Applications of fabric for shoes

- 3 Common User Pain Points for ‘fabric for shoes’ & Their Solutions

- Strategic Material Selection Guide for fabric for shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric for shoes

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for shoes’

- Comprehensive Cost and Pricing Analysis for fabric for shoes Sourcing

- Alternatives Analysis: Comparing fabric for shoes With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric for shoes

- Navigating Market Dynamics and Sourcing Trends in the fabric for shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric for shoes

- Strategic Sourcing Conclusion and Outlook for fabric for shoes

- Important Disclaimer & Terms of Use

Understanding fabric for shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nylon | Lightweight, durable, high abrasion resistance | Athletic footwear, casual shoes | Pros: Strong and flexible; Cons: Can be less breathable than natural fibers. |

| Polyester | Excellent color retention, quick-drying | Fashion shoes, outdoor footwear | Pros: Cost-effective and durable; Cons: Less stretchability compared to Lycra. |

| Cotton Canvas | Natural fiber, great for vulcanized shoes | Casual and lifestyle footwear | Pros: Breathable and easily dyed; Cons: Less durable than synthetic options. |

| Lycra | Highly elastic, moisture-wicking | Performance and sports shoes | Pros: Excellent fit and comfort; Cons: Can degrade under UV exposure. |

| PU Coated Fabric | Waterproof, strong backing | Waterproof shoes, work boots | Pros: Durable and weather-resistant; Cons: Heavier than other options. |

What Are the Characteristics and Suitability of Nylon for Footwear?

Nylon is a synthetic fabric known for its lightweight and durable properties, making it an ideal choice for athletic and casual footwear. Its high abrasion resistance ensures longevity even under strenuous conditions, appealing to brands targeting performance-driven consumers. When purchasing nylon, B2B buyers should consider the denier rating, as higher denier fabrics offer increased durability. Additionally, buyers should assess the fabric’s finish, which can enhance water resistance and overall performance.

How Does Polyester Compare in Terms of Performance and Cost?

Polyester is another popular synthetic fabric favored for its excellent color retention and quick-drying capabilities. This makes it a go-to material for fashion shoes and outdoor footwear, where style and practicality are essential. B2B buyers appreciate polyester’s cost-effectiveness, allowing for competitive pricing in the market. However, it’s important to note that polyester lacks the stretchability found in other fabrics like Lycra, which may limit its use in specific performance applications.

Why is Cotton Canvas a Preferred Choice for Casual Footwear?

Cotton canvas is a natural fiber that offers breathability and comfort, making it highly suitable for casual and lifestyle footwear. Its ability to be easily dyed allows manufacturers to create vibrant designs, appealing to a wide consumer base. However, B2B buyers should be aware that cotton canvas may not match the durability of synthetic materials, particularly in high-wear applications. When sourcing cotton canvas, consider factors like fabric weight and finish, which can impact the final product’s performance.

What Makes Lycra an Ideal Material for Performance Footwear?

Lycra is renowned for its exceptional elasticity and moisture-wicking properties, making it a preferred choice for performance and sports shoes. Its ability to provide a snug fit enhances comfort and support during physical activities. B2B buyers should evaluate the fabric’s UV resistance, as Lycra can degrade under prolonged sun exposure. Additionally, understanding the blend ratios with other materials can help in achieving desired performance characteristics while maintaining cost-effectiveness.

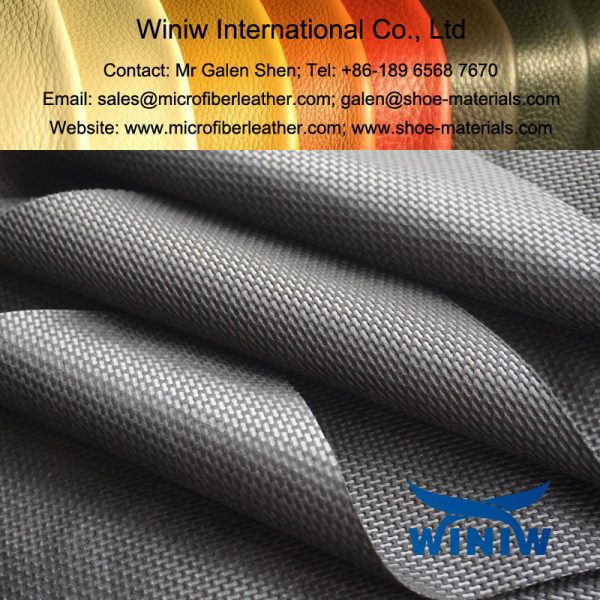

How Does PU Coated Fabric Enhance Waterproofing in Footwear?

PU (polyurethane) coated fabric is distinguished by its strong backing and waterproof capabilities, making it ideal for waterproof shoes and work boots. This material offers excellent durability and weather resistance, appealing to buyers in industries requiring protective footwear. However, the heavier weight of PU coated fabrics compared to lighter options may be a consideration for brands focused on comfort. When sourcing PU fabrics, buyers should assess the thickness and coating quality to ensure optimal performance for their specific applications.

Illustrative image related to fabric for shoes

Key Industrial Applications of fabric for shoes

| Industry/Sector | Specific Application of fabric for shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Production of athletic and casual footwear | Enhanced performance and comfort for end-users | Quality of fibers (e.g., nylon, polyester), durability, and compliance with international standards. |

| Fashion Retail | Customization of stylish and trendy shoe designs | Differentiation in a competitive market | Availability of diverse fabrics, color options, and design flexibility. |

| Safety and Industrial | Development of safety shoes for hazardous environments | Improved worker safety and compliance with regulations | Resistance to wear, chemical exposure, and certification for safety standards. |

| Outdoor and Sports Gear | Creation of specialized footwear for outdoor activities | Enhanced performance in rugged conditions | Water resistance, breathability, and lightweight properties of fabrics. |

| Children’s Footwear | Manufacturing of durable and comfortable kids’ shoes | Meeting the needs of active children and parents | Safety certifications, non-toxic materials, and ease of cleaning. |

How is fabric for shoes used in Footwear Manufacturing?

In the footwear manufacturing sector, fabrics are integral to producing athletic and casual shoes. Lightweight materials like nylon and polyester are favored for their durability and comfort, enhancing overall user experience. Manufacturers prioritize sourcing high-quality fibers that meet international standards to ensure longevity and performance. For international buyers, understanding the specific fabric compositions and their benefits can lead to better product offerings in competitive markets.

What role does fabric play in Fashion Retail?

Fashion retail heavily relies on fabric for customization and design flexibility in shoe production. The ability to source unique textiles allows brands to create stylish and trendy footwear that stands out in a crowded marketplace. Buyers in this sector should focus on the availability of diverse fabric options, including patterns and colors that align with current fashion trends, ensuring their products appeal to consumers and maintain a competitive edge.

How is fabric utilized in Safety and Industrial applications?

In the safety and industrial sector, fabric is crucial for manufacturing shoes designed for hazardous work environments. These shoes often incorporate robust materials that provide resistance to wear, chemicals, and other workplace hazards, ensuring compliance with safety regulations. For B2B buyers, sourcing fabrics that meet specific safety certifications is essential, as it guarantees that the footwear will protect workers effectively while also adhering to legal requirements.

What are the advantages of fabric in Outdoor and Sports Gear?

Outdoor and sports gear industries benefit from specialized footwear that utilizes advanced fabrics designed for performance in rugged conditions. Waterproof and breathable materials are essential for ensuring comfort during outdoor activities. Buyers in this sector should consider sourcing fabrics that offer lightweight properties and durability to withstand various environmental challenges, enhancing the functionality of their products.

How is fabric important for Children’s Footwear?

The children’s footwear market demands fabrics that combine durability with comfort, catering to the active lifestyles of children. Sourcing non-toxic and safe materials is paramount, as parents prioritize safety in their purchasing decisions. Additionally, fabrics that are easy to clean and maintain add value for buyers targeting this demographic. By focusing on these requirements, businesses can effectively meet market demands while ensuring the safety and satisfaction of their young consumers.

Illustrative image related to fabric for shoes

3 Common User Pain Points for ‘fabric for shoes’ & Their Solutions

Scenario 1: Sourcing Quality Fabric That Meets Diverse Needs

The Problem: B2B buyers often struggle with sourcing high-quality fabrics that cater to various shoe designs and consumer preferences. This challenge can be exacerbated by the wide variety of textiles available, each with different properties such as durability, weight, and aesthetics. Buyers may find themselves overwhelmed by choices, leading to indecision or, worse, the procurement of subpar materials that don’t align with their brand standards. Additionally, fluctuating global market conditions can impact the availability and pricing of certain fabrics, making it difficult to maintain consistent product offerings.

The Solution: To effectively source quality fabric for shoes, B2B buyers should conduct thorough market research to identify reputable suppliers known for their specialty textiles. Establish relationships with multiple suppliers to diversify sourcing options, which can help mitigate risks associated with price fluctuations or shortages. Utilize samples to evaluate fabric quality, ensuring they meet the required specifications for weight, durability, and finish. Additionally, leverage technology, such as digital fabric libraries, to streamline the selection process. This proactive approach allows buyers to align their fabric choices with their design vision and consumer expectations, ensuring a high-quality end product.

Scenario 2: Navigating Fabric Import Regulations and Duties

The Problem: Importing textile materials can present a significant challenge due to complex regulations and high duties imposed by various countries. B2B buyers may encounter unexpected costs that impact their profit margins, especially when importing textiles that exceed certain surface area thresholds. Furthermore, failure to comply with local regulations can lead to delays in production or shipment, creating a ripple effect on delivery schedules and customer satisfaction.

The Solution: To navigate import regulations effectively, B2B buyers should invest time in understanding the specific rules governing textile imports in their target markets. This includes familiarizing themselves with the Harmonized System (HS) codes relevant to their products and the associated duty rates. Collaborating with customs brokers can provide valuable insights and ensure compliance with all regulatory requirements. Additionally, buyers should explore sourcing fabrics that can minimize duty costs, such as those with lower textile surface area percentages or alternative constructions that qualify for reduced rates. Staying updated on trade agreements and tariff changes can also help buyers strategically plan their sourcing and import activities.

Scenario 3: Ensuring Fabric Sustainability and Ethical Sourcing

The Problem: Increasingly, consumers and brands are prioritizing sustainability and ethical sourcing in their purchasing decisions. B2B buyers face the challenge of finding fabrics that not only meet performance and aesthetic criteria but also align with environmentally friendly practices. The lack of transparency in the supply chain can make it difficult for buyers to verify the sustainability claims of fabric suppliers, leading to potential reputational risks for their brands.

The Solution: To ensure sustainable and ethically sourced fabrics, B2B buyers should establish clear criteria for sustainability when evaluating suppliers. This could include certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which verify environmentally friendly practices and safe working conditions. Conducting audits or site visits to suppliers can further enhance transparency and trust in the sourcing process. Buyers should also consider collaborating with suppliers who are committed to sustainability, as this can lead to innovative fabric options that meet both performance and ethical standards. By prioritizing sustainability, buyers can not only enhance their brand’s reputation but also contribute positively to the global textile industry.

Strategic Material Selection Guide for fabric for shoes

When selecting fabrics for shoe manufacturing, it is essential to understand the properties and applications of various materials. This analysis focuses on four common fabrics used in the footwear industry: polyester, nylon, cotton canvas, and Lycra. Each material has unique characteristics that influence its suitability for different shoe types, performance standards, and market preferences.

What Are the Key Properties of Polyester for Shoe Fabric?

Polyester is a synthetic fiber known for its durability and resistance to shrinking and stretching. It has good moisture-wicking properties, making it suitable for athletic and casual footwear. Polyester can withstand a wide range of temperatures, typically rated for use in environments from -40°C to 120°C, depending on the specific formulation.

Pros & Cons: Polyester is relatively inexpensive and easy to manufacture, which contributes to its widespread use in the industry. However, it may not be as breathable as natural fibers, which can impact comfort during prolonged wear. Additionally, while polyester is resistant to mildew and mold, it can be prone to static electricity.

Illustrative image related to fabric for shoes

Impact on Application: Polyester’s moisture-wicking ability makes it ideal for sports shoes, while its durability suits casual and formal footwear. International buyers should consider compliance with standards such as ASTM for flammability and performance.

How Does Nylon Perform as a Shoe Fabric?

Nylon is another synthetic fabric that offers excellent strength and elasticity. It is lightweight and highly resistant to abrasion, making it ideal for high-performance footwear. Nylon can typically handle temperatures up to 150°C, providing versatility in various applications.

Pros & Cons: The key advantage of nylon is its high tensile strength, which translates to long-lasting products. However, it can be more expensive than polyester and may require more complex manufacturing processes. Additionally, nylon is less environmentally friendly, which may be a concern for buyers focused on sustainability.

Illustrative image related to fabric for shoes

Impact on Application: Nylon is particularly suitable for outdoor and athletic shoes, where durability and performance are critical. Buyers in regions like Europe and the Middle East may prioritize nylon for its strength but should also consider environmental regulations regarding synthetic materials.

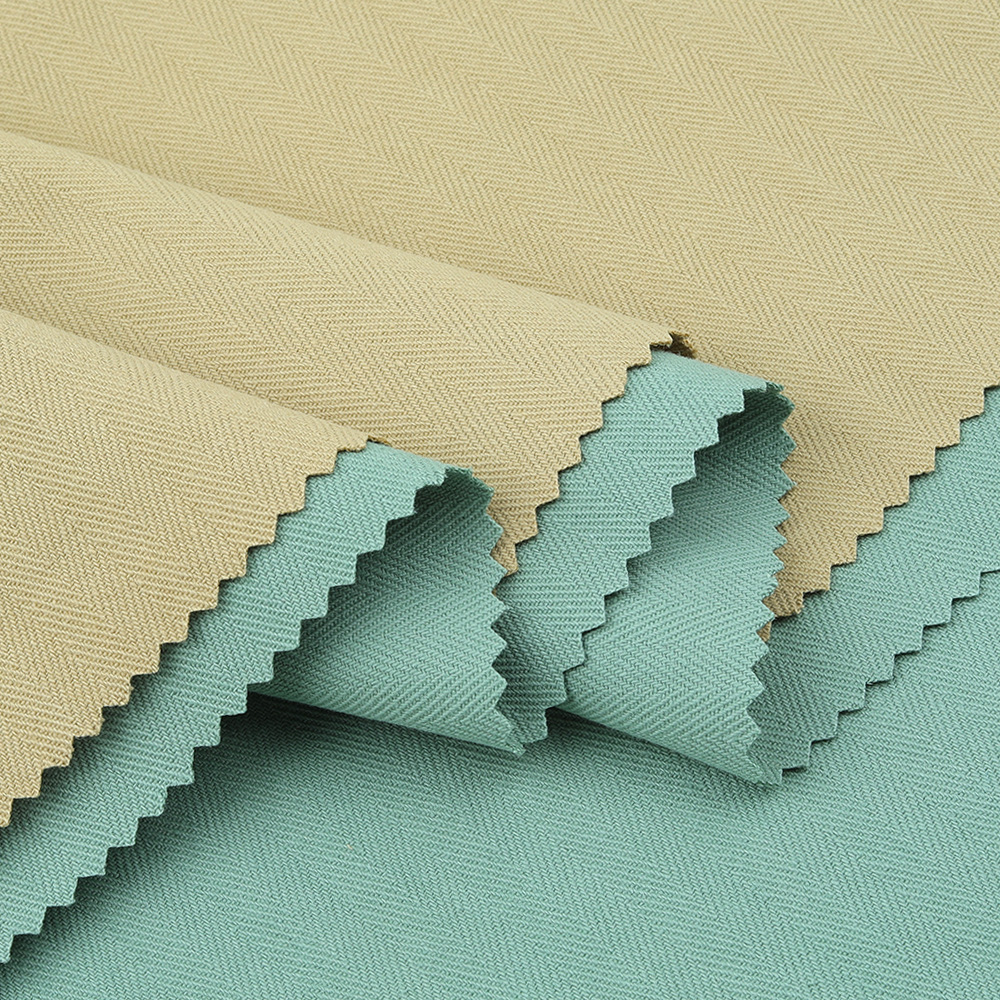

What Are the Advantages of Cotton Canvas in Footwear?

Cotton canvas is a natural fiber known for its breathability and comfort. It is often used in casual and vulcanized shoes, where flexibility and ease of wear are essential. Cotton can absorb moisture, making it suitable for warm climates, though it has lower temperature resistance compared to synthetic fibers.

Pros & Cons: The primary advantage of cotton canvas is its comfort and aesthetic appeal, which can be enhanced through various treatments. However, it is less durable than synthetic options and can be prone to wear and tear over time. Additionally, cotton requires more care in maintenance, as it can shrink or fade with washing.

Impact on Application: Cotton canvas is favored for casual footwear, particularly in markets with warm climates such as Africa and South America. Buyers should ensure compliance with local textile regulations and consider the environmental impact of cotton farming.

Why Is Lycra Important in Shoe Fabric Applications?

Lycra, or spandex, is a synthetic fiber known for its exceptional elasticity. It is often blended with other materials to enhance stretchability, making it ideal for shoe linings and bindings. Lycra can withstand temperatures up to 90°C and offers excellent recovery after stretching.

Pros & Cons: The key advantage of Lycra is its ability to provide a snug fit, enhancing comfort and performance in athletic footwear. However, it is typically more expensive than other materials and may require specific manufacturing techniques. Additionally, Lycra is not as durable as other fabrics when exposed to harsh conditions.

Impact on Application: Lycra is commonly used in performance footwear, especially in markets focused on sports and active lifestyles. International buyers should be aware of standards related to elasticity and performance, particularly in competitive sports markets.

Illustrative image related to fabric for shoes

Summary Table of Fabric Properties for Shoe Manufacturing

| Material | Typical Use Case for fabric for shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Athletic and casual footwear | Durable and moisture-wicking | Less breathable than natural fibers | Low |

| Nylon | Outdoor and athletic shoes | High tensile strength | More expensive and less eco-friendly | Medium |

| Cotton Canvas | Casual and vulcanized shoes | Comfortable and breathable | Less durable and prone to wear | Low |

| Lycra | Performance footwear linings | Exceptional elasticity | More expensive and less durable | Medium |

This guide provides B2B buyers with critical insights into material selection for footwear, emphasizing the importance of understanding each fabric’s properties, advantages, and limitations. By considering these factors, businesses can make informed decisions that align with market demands and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric for shoes

What Are the Main Stages in the Manufacturing Process for Shoe Fabrics?

The manufacturing process for fabrics used in shoe production consists of several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages allows B2B buyers to assess the quality and suitability of fabric suppliers.

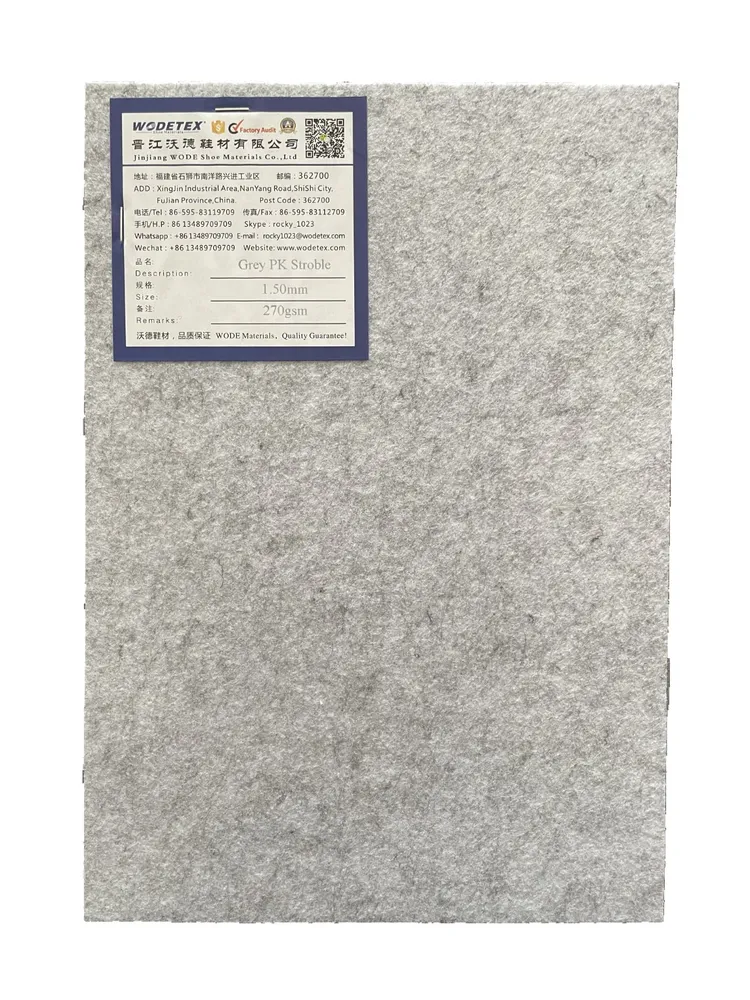

How Does Material Preparation Impact Fabric Quality?

Material preparation is the foundational step in fabric manufacturing, where raw fibers are selected based on their properties and intended use. Common fibers include nylon, polyester, cotton, and lycra, each offering unique characteristics such as durability, stretchability, and moisture management.

In this phase, suppliers often conduct tests to verify fiber quality, including moisture regain, tensile strength, and colorfastness. High-quality materials are essential for ensuring longevity and performance in shoe design, which is particularly important for international buyers seeking reliability in various climates and usage conditions.

What Techniques Are Used in the Forming Stage?

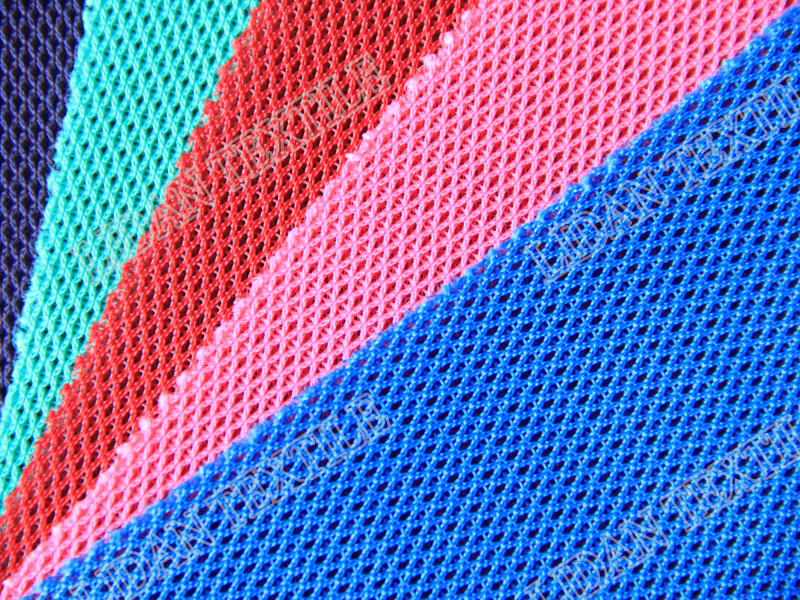

Once materials are prepared, the forming stage begins. This involves weaving or knitting the fibers into fabric. Woven fabrics are created by interlacing warp and weft threads, while knitted fabrics utilize a series of loops that allow for greater elasticity.

Illustrative image related to fabric for shoes

Advanced techniques such as air mesh or 3D mesh construction are gaining popularity in sports footwear, providing breathability and comfort. The choice between woven and knitted fabrics can significantly affect the final product’s functionality, weight, and aesthetic appeal.

How Does the Assembly Process Ensure Fabric Integrity?

During the assembly phase, various fabric components are cut and sewn together to form the shoe. Quality assurance is crucial here, as improper assembly can lead to defects such as misaligned seams or weak joints.

B2B buyers should look for suppliers who utilize automated cutting and sewing machines, as these technologies enhance precision and reduce human error. Additionally, lamination processes may be employed, where a layer of foam is added to the fabric to improve durability and comfort.

Illustrative image related to fabric for shoes

What Are the Key Finishing Techniques That Enhance Fabric Performance?

The finishing stage is where fabrics are treated to enhance their performance characteristics. Common finishing techniques include dyeing, waterproofing, and applying surface treatments like Durable Water Repellent (DWR) coatings.

These treatments not only improve the visual appeal but also extend the fabric’s lifespan by making it resistant to environmental factors. Buyers should inquire about the types of finishes used, as these can greatly affect the fabric’s performance in different markets, particularly in regions with diverse weather conditions.

How Is Quality Assurance Implemented in Fabric Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets both industry standards and buyer expectations.

Illustrative image related to fabric for shoes

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with international quality standards such as ISO 9001, which focuses on quality management systems, and other industry-specific certifications like CE marking for safety and compliance. Compliance with these standards indicates a supplier’s commitment to quality and customer satisfaction.

What Are the Key Quality Control Checkpoints in Fabric Production?

Quality control in fabric manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage assesses raw materials for defects before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, ongoing inspections ensure that processes adhere to specifications and standards.

-

Final Quality Control (FQC): Before products are shipped, a final inspection checks for defects, color consistency, and overall quality.

Each checkpoint is crucial for identifying issues early in the process, reducing waste, and ensuring that only high-quality fabrics reach the buyer.

What Testing Methods Are Commonly Used to Ensure Fabric Quality?

To verify fabric quality, suppliers often employ various testing methods, including:

- Tensile Strength Testing: Evaluates the fabric’s ability to withstand tension.

- Abrasion Resistance Testing: Determines how well the fabric can endure wear and tear.

- Water Resistance Testing: Assesses the fabric’s ability to repel water, which is essential for outdoor and sports footwear.

These tests should be documented and available for buyer review, providing transparency in quality assurance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of a supplier’s quality control practices is crucial for B2B buyers, especially when sourcing from international markets.

What Audit Processes Should Buyers Consider?

Buyers can conduct audits of potential suppliers, focusing on their manufacturing processes, quality control systems, and compliance with industry standards. This can include on-site visits or third-party audits by certification bodies.

How Can Buyers Utilize Reports and Third-Party Inspections?

Requesting quality reports and certifications from suppliers can provide insight into their QA practices. Third-party inspections can also serve as an unbiased assessment of fabric quality, helping buyers make informed decisions.

What Nuances Exist for International Buyers in Terms of QC?

International buyers, particularly those from regions like Africa, South America, and the Middle East, should be aware of specific nuances in quality control. Import regulations and duties may vary significantly, affecting the overall cost and feasibility of sourcing materials. Understanding local regulations and ensuring that suppliers are compliant with both local and international standards is essential to avoid delays and additional costs.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices for fabrics used in shoe production is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, as well as implementing robust quality control measures, buyers can ensure they source high-quality fabrics that meet their specifications. This knowledge empowers buyers to build strong relationships with suppliers and make informed purchasing decisions that align with their business goals.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for shoes’

Introduction

Sourcing the right fabric for shoes is a critical component of successful footwear production. This guide provides a structured checklist for B2B buyers to ensure they procure fabrics that meet their design, durability, and cost requirements. By following these steps, you can streamline your sourcing process and make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Before initiating your search for fabric, clearly outline your technical requirements. This includes specifying the type of fabric, weight, durability, stretchability, and any specific certifications needed. Defining these criteria will help narrow down your options and ensure that the fabrics you consider will meet the functional and aesthetic demands of your shoe designs.

Step 2: Identify Target Fabrics and Materials

Research and compile a list of suitable fabric types for your shoe designs. Popular options include polyester, nylon, cotton canvas, and lycra, each offering unique properties such as water resistance and stretchability. Understanding the characteristics of these materials will allow you to select fabrics that not only look good but also perform well in the intended environment.

Step 3: Evaluate Supplier Capabilities

Thoroughly assess potential suppliers to ensure they can meet your requirements. Request detailed information about their manufacturing processes, quality control measures, and capacity for custom orders. Look for suppliers with a proven track record in the footwear industry and those who can provide samples for testing.

Illustrative image related to fabric for shoes

- Check certifications: Ensure suppliers comply with relevant industry standards and regulations for textile production.

Step 4: Request and Review Samples

Before making a bulk purchase, request samples of the fabrics you are considering. This allows you to evaluate their quality, texture, and suitability for your designs. Pay attention to how the fabric performs under different conditions, such as stretching, water exposure, and wear.

- Conduct tests: Perform any necessary tests to assess durability, colorfastness, and compatibility with your manufacturing processes.

Step 5: Negotiate Pricing and Terms

Once you have selected a suitable supplier and fabric, initiate negotiations on pricing and terms. Consider factors such as minimum order quantities, payment terms, and delivery schedules. A transparent negotiation process can help establish a mutually beneficial relationship.

- Discuss import duties: Be aware of potential import duties based on the fabric type and origin, as these can significantly affect your overall costs.

Step 6: Finalize Contracts and Agreements

After agreeing on terms, ensure that all details are documented in a formal contract. This should include specifications, delivery timelines, payment terms, and quality assurance protocols. A well-drafted agreement protects both parties and provides a clear framework for the sourcing process.

Step 7: Monitor and Evaluate Supplier Performance

Once you begin sourcing fabrics, continuously monitor the supplier’s performance regarding quality, delivery times, and responsiveness. Regular evaluations will help you identify any issues early and ensure a steady supply of materials that meet your standards.

Illustrative image related to fabric for shoes

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing fabric for shoes, ensuring they select materials that align with their brand’s quality and design vision.

Comprehensive Cost and Pricing Analysis for fabric for shoes Sourcing

What Are the Key Cost Components in Sourcing Fabric for Shoes?

When sourcing fabric for shoes, understanding the cost structure is essential for effective budgeting and pricing strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The fabric itself represents a significant portion of the total cost. Prices vary widely depending on the type of fiber (e.g., polyester, nylon, cotton), with synthetic materials typically being less expensive than natural fibers. Specialty fabrics with unique properties, such as water resistance or stretchability, can also drive up costs.

-

Labor: Labor costs are influenced by the region where the fabric is produced. Countries with lower labor costs may offer cheaper fabric options, but this can come at the expense of quality. Understanding the labor market in your supplier’s location is crucial for estimating total costs.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses incurred during production. Suppliers often factor these overhead costs into the pricing of their fabrics, so it’s essential to consider them when comparing quotes.

-

Tooling: Initial tooling costs, such as molds or specialized machinery for unique fabric treatments, can be significant. These costs are often spread across production runs, which means that larger orders can lead to lower per-unit costs.

-

Quality Control (QC): Implementing a rigorous QC process ensures that the fabric meets specified standards. However, this adds to the overall cost. Buyers should assess the level of QC their suppliers offer and determine if it aligns with their quality expectations.

-

Logistics: Shipping costs can vary greatly depending on the origin of the fabric and the destination market. Factors like distance, shipping mode, and Incoterms impact logistics costs. Consider these when evaluating total expenses.

-

Margin: Finally, suppliers will add their profit margin to the cost of the fabric. This margin can vary based on market demand, competition, and the supplier’s brand reputation.

How Do Price Influencers Affect the Sourcing of Fabric for Shoes?

Several factors can influence the price of fabric for shoes, making it essential for buyers to conduct thorough research before making purchasing decisions.

-

Volume/MOQ: Minimum order quantities (MOQ) and order volume can significantly affect pricing. Suppliers often offer discounts for bulk purchases, making it more cost-effective for buyers who can commit to larger orders.

-

Specifications and Customization: Fabrics tailored to specific design requirements or those that require unique characteristics will typically incur higher costs. Customization can involve more complex manufacturing processes, which can increase both materials and labor costs.

-

Quality and Certifications: Fabrics that come with certifications (e.g., eco-friendly, hypoallergenic) may command higher prices. However, these certifications can enhance the marketability of the final product, potentially justifying the cost.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can influence pricing. Established suppliers may charge more due to their proven track record, while newer or less reliable suppliers may offer lower prices but come with higher risks.

-

Incoterms: The terms of sale can affect the final cost. Understanding who bears the responsibility for shipping, insurance, and customs can help buyers avoid unexpected expenses.

What Are Effective Buyer Tips for Cost-Efficiency in Fabric Sourcing?

To maximize cost-efficiency when sourcing fabric for shoes, consider the following tips:

-

Negotiate: Don’t hesitate to negotiate prices with suppliers. Building a relationship can lead to better deals over time, especially for repeat orders.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term costs associated with quality, durability, and potential returns due to defects.

-

Understand Pricing Nuances: For international buyers, be aware of currency fluctuations and how they may affect costs. Additionally, familiarize yourself with local import duties and tariffs that could impact the total cost of fabric.

-

Research Supplier Markets: Different regions may offer varying pricing structures. For instance, suppliers in Southeast Asia might provide competitive rates compared to those in Europe, but consider quality and reliability as well.

-

Stay Informed: Keep abreast of industry trends, as market dynamics can shift pricing. Understanding the broader economic landscape can help buyers make informed decisions.

Disclaimer

The prices and cost structures discussed in this analysis are indicative and may vary based on specific circumstances, including supplier negotiations, regional economic conditions, and changes in material costs. Always conduct thorough research and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing fabric for shoes With Other Solutions

Understanding Alternative Solutions in Shoe Material Selection

When selecting materials for shoe production, it is essential to evaluate not only traditional fabrics but also alternative solutions that may meet the specific needs of various markets. In this analysis, we will compare ‘fabric for shoes’ against two viable alternatives: synthetic leather and molded rubber. Each option has distinct characteristics that could impact performance, cost, and usability, especially for international B2B buyers targeting diverse regions.

Illustrative image related to fabric for shoes

| Comparison Aspect | Fabric For Shoes | Synthetic Leather | Molded Rubber |

|---|---|---|---|

| Performance | Lightweight, breathable, and versatile. Good moisture management but may wear over time. | Durable and water-resistant. Mimics leather but lacks breathability. | Highly durable and water-resistant. Excellent grip and shock absorption. |

| Cost | Moderate to high, depending on fiber and treatment. | Generally lower than genuine leather but higher than basic fabrics. | Lower than fabrics and synthetic leather, especially in bulk. |

| Ease of Implementation | Requires specific sewing techniques and finishing processes. | Easier to cut and sew; often requires fewer specialized skills. | Generally simpler to mold, but requires specialized machinery for production. |

| Maintenance | Requires regular cleaning and possible re-treatment. | Easy to clean; resistant to stains and moisture. | Low maintenance; very durable against wear and tear. |

| Best Use Case | Ideal for fashion-forward, lightweight footwear, and sports shoes. | Suitable for mid-range to high-end markets needing a leather-like finish without animal products. | Best for work boots, casual shoes, or footwear requiring high durability and weather resistance. |

Evaluating Synthetic Leather as an Alternative

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is a popular alternative for shoe production. Its primary advantage lies in its durability and water resistance, making it ideal for various shoe applications, from casual to formal footwear. The ease of cleaning and maintenance adds to its appeal, particularly for B2B buyers catering to fast-fashion markets. However, synthetic leather typically lacks breathability compared to fabric options, which can lead to discomfort in warmer climates.

Analyzing Molded Rubber for Footwear Solutions

Molded rubber is another alternative gaining traction in the shoe manufacturing industry. Known for its exceptional durability and water resistance, molded rubber provides excellent grip and shock absorption, making it ideal for athletic and outdoor footwear. The production process is generally more straightforward, allowing for mass production without extensive labor costs. However, molded rubber can be heavier than fabric or synthetic leather, potentially limiting its application in lightweight footwear. Additionally, while it excels in durability, its aesthetic appeal may not match that of traditional fabrics or synthetic alternatives.

How to Choose the Right Solution for Your Footwear Needs

In conclusion, selecting the appropriate material for shoes hinges on various factors, including the target market, desired performance characteristics, and cost considerations. B2B buyers should assess the specific requirements of their clientele—such as the need for lightweight, breathable options versus durable, water-resistant alternatives. By thoroughly evaluating the pros and cons of fabrics, synthetic leather, and molded rubber, buyers can make informed decisions that align with their business goals and consumer preferences.

Essential Technical Properties and Trade Terminology for fabric for shoes

What are the Key Technical Properties of Fabrics for Shoes?

When sourcing fabrics for shoe manufacturing, understanding the technical specifications is critical. Here are some essential properties to consider:

-

Denier (D)

– Denier is a unit of measurement that indicates the thickness of the thread used in fabric. It is defined as the weight in grams of 9,000 meters of thread. Common denier values for shoe fabrics range from 110D for lightweight applications to 1000D for heavy-duty items like boots. For B2B buyers, denier helps assess the fabric’s strength and durability, informing decisions on suitability for different shoe types. -

Fiber Composition

– Fabrics can be made from various fibers, including natural (cotton, wool) and synthetic (nylon, polyester). Each fiber type has unique properties such as water absorption, stretchability, and UV resistance. Understanding fiber composition is essential for buyers to ensure the fabric meets performance requirements and aligns with brand values, particularly regarding sustainability. -

Weave Pattern

– The method of weaving the fibers significantly impacts the fabric’s texture, strength, and elasticity. Common weave types include plain, twill, and satin. Each pattern offers different benefits, such as breathability or stretch. For B2B buyers, choosing the right weave can enhance the comfort and functionality of the final shoe product. -

Backing Material

– Backing materials, such as PU (polyurethane) and PVC (polyvinyl chloride), provide added durability and waterproofing. PU is lighter and less expensive, while PVC offers more robust protection. Buyers must consider backing materials to ensure the fabric meets specific performance criteria, especially for outdoor or athletic footwear. -

Surface Treatments

– Fabrics can undergo various surface treatments, such as Durable Water Resistance (DWR) or brushing, which enhance performance characteristics. These treatments can improve water resistance, softness, or overall aesthetic appeal. Buyers should evaluate surface treatments to ensure they align with the intended use and consumer expectations.

What Common Trade Terms Should B2B Buyers Know When Sourcing Shoe Fabrics?

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products or components that are purchased by another company and sold under that company’s brand name. Understanding OEM relationships is crucial for buyers to ensure quality control and adherence to specifications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. It is essential for buyers to know MOQ to manage inventory effectively and ensure cost-efficiency in their sourcing strategies. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a quote for a specific quantity of goods. This process is vital for comparing prices, terms, and supplier capabilities, allowing buyers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– These are standardized trade terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers navigate shipping, insurance, and risk management effectively. -

Lead Time

– Lead time refers to the duration from placing an order to the delivery of goods. Understanding lead times is critical for buyers to plan production schedules and meet market demands without delays. -

Certification Standards

– Many fabrics come with certifications that indicate compliance with specific industry standards (e.g., ISO, Oeko-Tex). These certifications can assure buyers of product safety and environmental compliance, influencing purchasing decisions.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing fabrics for shoes, ensuring they meet quality, performance, and compliance standards while optimizing supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the fabric for shoes Sector

What Are the Key Drivers and Trends Shaping the Global Fabric for Shoes Market?

The global fabric for shoes market is experiencing dynamic shifts driven by various factors. One significant driver is the growing demand for lightweight, durable materials that enhance performance and comfort. Innovations in textile technology, such as moisture-wicking fabrics and breathable meshes, are emerging to meet the needs of active consumers. Additionally, the rise of e-commerce has enabled manufacturers to reach international B2B buyers more effectively, especially in regions like Africa, South America, and the Middle East, where traditional retail channels may be less developed.

Emerging trends include the integration of smart textiles into footwear, which can monitor health metrics or adapt to environmental conditions. The use of 3D knitting technology is also gaining traction, allowing for customization and reduced waste during production. Buyers are increasingly looking for suppliers who can provide not only quality fabrics but also advanced technology solutions that align with their brand ethos.

Furthermore, the demand for sustainable and ethically sourced materials is reshaping sourcing strategies. B2B buyers are now prioritizing suppliers who adhere to transparent supply chains and offer certifications for eco-friendly materials. As the market evolves, understanding these dynamics will be crucial for international buyers seeking to make informed sourcing decisions.

How Is Sustainability Influencing the Sourcing of Fabric for Shoes?

Sustainability is becoming a cornerstone of the fabric for shoes sector, significantly influencing sourcing practices. The environmental impact of textile production, particularly in terms of water usage, chemical runoff, and waste generation, has prompted a shift towards more sustainable practices. B2B buyers are increasingly evaluating suppliers based on their commitment to reducing carbon footprints and implementing circular economy principles.

Ethical sourcing is equally critical, as consumers demand transparency in the supply chain. Brands that prioritize ethical practices not only enhance their reputation but also cater to a growing market segment that values sustainability. Buyers are encouraged to seek out certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which ensure that the materials meet environmental and social criteria.

Additionally, the rise of alternative materials, such as recycled fabrics or bio-based textiles, is transforming the landscape. These innovative options not only reduce reliance on virgin resources but also appeal to consumers seeking eco-friendly choices. For international buyers, aligning sourcing strategies with sustainability goals will not only meet market demand but also position their brands as leaders in the responsible fashion movement.

How Has the Fabric for Shoes Market Evolved Over Time?

The evolution of the fabric for shoes market has been marked by significant technological advancements and shifts in consumer preferences. Historically, footwear materials were limited to natural fibers, such as leather and cotton. However, the mid-20th century saw the introduction of synthetic materials like nylon and polyester, which revolutionized shoe design by offering greater durability and flexibility.

As consumer awareness grew around environmental issues, the industry began to pivot towards sustainable practices, leading to the development of recycled and organic materials. Today, buyers are not only focused on the functional aspects of fabrics but also on their environmental and ethical implications. This evolution highlights the importance of innovation and adaptability in the fabric for shoes sector, as brands strive to meet the changing demands of a conscious consumer base. For B2B buyers, understanding this historical context can provide valuable insights into current market dynamics and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric for shoes

-

How do I choose the right fabric for my shoe design?

Selecting the appropriate fabric for shoe design involves evaluating several key factors. Begin with the intended use of the shoe, as performance requirements will dictate material choice. Consider the fiber composition (e.g., cotton for vulcanized shoes or nylon for durability), the weight (denier), and weave type (woven vs. knitted) for elasticity and strength. Also, assess surface treatments for water resistance or durability. Finally, ensure that the fabric aligns with your brand’s aesthetic and functionality needs while being mindful of import regulations in your target market. -

What types of fabrics are commonly used in shoe manufacturing?

The most popular fabrics in shoe manufacturing include nylon, polyester, cotton, and lycra. Nylon and polyester are favored for their durability and lightweight properties, making them ideal for various footwear applications. Cotton is essential for vulcanized shoes due to its heat resistance, while lycra is commonly used in linings and bindings for its stretchability. Additionally, consider high-tech options like air mesh for breathability and comfort. Understanding the strengths of each fabric type will help you select the best material for your specific shoe design. -

What are the minimum order quantities (MOQs) for fabric suppliers?

Minimum order quantities (MOQs) can vary significantly based on the supplier, fabric type, and customization requirements. Typically, MOQs for fabrics can range from 100 to 1,000 meters. Custom designs or specialty fabrics may have higher MOQs. When sourcing fabrics, it’s essential to communicate your needs clearly to suppliers and inquire about their flexibility regarding MOQs, especially if you are a smaller business or testing a new product line. Building a relationship with suppliers can sometimes lead to more favorable terms. -

How can I ensure quality assurance (QA) for the fabrics I purchase?

To ensure quality assurance when sourcing fabrics, establish clear specifications and standards before placing orders. Request samples to evaluate the fabric’s texture, durability, and performance characteristics. Consider implementing a third-party inspection service to conduct quality checks during production and before shipment. Additionally, maintain open communication with your supplier regarding any concerns and establish a clear return policy for defective materials. Documenting these processes will help mitigate risks associated with quality issues. -

What are the payment terms typically offered by fabric suppliers?

Payment terms can vary widely among fabric suppliers, but common practices include upfront payments, deposits (e.g., 30% upfront, 70% upon delivery), or net payment terms (e.g., net 30 or net 60 days). It’s crucial to negotiate payment terms that align with your cash flow and purchasing strategy. Always clarify these terms in the purchase agreement to avoid misunderstandings. Consider using secure payment methods that offer buyer protection, especially when dealing with international suppliers. -

How do I vet suppliers for sourcing fabric for shoes?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with industry standards. Start by checking online reviews, industry certifications, and case studies from other B2B buyers. Request references and follow up with past clients to gauge their experience. Additionally, consider visiting the supplier’s facility if feasible, or using virtual tours. Ensure they have the capacity to meet your order requirements and that they adhere to ethical practices, especially concerning labor and environmental standards. -

What logistics considerations should I keep in mind when importing fabric?

When importing fabric, logistics play a crucial role in ensuring timely delivery and cost efficiency. Understand the customs regulations and duties applicable to your destination country, as these can significantly impact your overall cost. Work with experienced freight forwarders who can navigate the complexities of international shipping. Additionally, consider factors such as shipping times, insurance for high-value shipments, and storage solutions upon arrival. Planning these logistics in advance can help avoid delays and additional costs. -

How can I customize fabric for my shoe designs?

Customization of fabric involves working closely with suppliers to achieve your desired design specifications. This can include choosing colors, patterns, or even specific performance attributes (like water resistance or breathability). Many suppliers offer digital printing or dyeing services, allowing for unique designs to be created. It’s essential to communicate your vision clearly and request samples of the customized fabric before placing large orders. Ensure you understand the lead times for custom orders, as they may differ from standard offerings.

Top 7 Fabric For Shoes Manufacturers & Suppliers List

1. Etsy – Shoe Fabric Selection

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Shoe Fabric available on Etsy includes various types such as NFL Team Cotton Fabric (100% Cotton, 58″ Wide, sold by the yard), High Quality YARD Leather (DIY Leather, faux leather, printed leather), Kids Fabric (100% Cotton, High Top Tennis Shoes), Dark Brown Check Faux Leather Sheet (8.25 x 11.5 Inches), and Loralie Designs Tossed Tennis Shoes Cotton Fabric (sold by the yard). Prices range from $…

2. Shoemakers Academy – Essential Textiles for Shoe Design

Domain: shoemakersacademy.com

Registered: 2022 (3 years)

Introduction: Textiles for Shoe Design: Understanding fabrics is essential for shoe design. Key textiles include nylon, polyester, lycra, and cotton canvas. Important considerations for textiles are thread size (measured in denier), fiber composition, weave pattern, backing material, sizing, and surface treatments. Typical deniers range from 110D for lightweight fabric to 1000D for boots. Common fiber types inc…

3. Shoe Print Fabric – Various Colors & Lengths

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Shoe Print Fabric available in various colors including Blue, Green, Black, Multicolor, White, Pink, Red, Beige, Gray, Brown, Purple, and Yellow. Length options include By the Yard, 1 – 2 yds, 3 – 5 yds, 6 – 12 yds, Fat Quarters, Bundles, Jelly Rolls, Strips, Less than 1 yd, Squares, Panels, and Bolts. The fabric is suitable for various applications such as apparel, quilting, crafts, upholstery, a…

4. Reddit – Canvas Slip-On Shoes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Fabric shoes, specifically canvas/twill slip-on shoes inspired by TOMS alpargatas/espadrilles. Designed for wide and flat feet. Issues with attaching fabric to midsole around heel curves. Suggestions include using triangle relief cuts for toe box and stitching darts for heel. Lining used for comfort, with potential use of twill instead of canvas.

5. Wendy Custom – Goyard Leather Fabric

Domain: wendycustom.com

Registered: 2022 (3 years)

Introduction: This company, Wendy Custom – Goyard Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Wei-Syun – Expert Fabrics for Shoes

Domain: monofabrics.com

Registered: 2018 (7 years)

Introduction: Expert Fabrics for Shoes | Wei-Syun – Trusted Shoes Fabric Manufacturer. 63 products in this line. Fabrics for shoe uppers include: Nylon mesh (lightweight, breathable, tear-resistant), Polyester mesh (lightweight, breathable, abrasion-resistant), Synthetic leather (durable, fashion-friendly), Neoprene (flexible, good stretch), TPU (durable, water-resistant, abrasion-resistant), MONO Monofilament …

7. Not All Fabric – Designer Fabrics for Custom Shoes

Domain: notallfabric.com

Registered: 2021 (4 years)

Introduction: Designer Fabric for DIY/Custom Shoes, Air Dior Swoosh for Shoes Decal, Jacquard Designer Fabric, CD Monogram Fabric, Various Color GG Monogram Fabric, Various Color CD Monogram Fabric, Blue Jacquard Designer Fabric, Rainbow Stripe GG Fabric, GG Designer Inspired Jacquard Fabric-Classic Tan, Red GG Designer Inspired Jacquard Fabric, Yellow GG Designer Inspired Jacquard Fabric, Blue GG Designer Insp…

Strategic Sourcing Conclusion and Outlook for fabric for shoes

In the competitive landscape of footwear manufacturing, strategic sourcing of fabrics is paramount for delivering innovative and high-quality products. International buyers must consider key attributes such as fiber composition, weave patterns, and surface treatments when selecting textiles. The choice of materials not only influences the aesthetic appeal of shoes but also impacts durability, comfort, and functionality. As markets across Africa, South America, the Middle East, and Europe continue to evolve, understanding local trends and consumer preferences will be crucial in making informed sourcing decisions.

Illustrative image related to fabric for shoes

Furthermore, navigating import regulations and duties can significantly affect cost structures, making it essential for buyers to stay updated on policies that may impact their supply chain. By fostering strong relationships with textile suppliers and investing in research and development, businesses can enhance their competitive edge in the global market.

Looking ahead, the demand for sustainable and innovative fabrics will only increase. B2B buyers are encouraged to explore new materials and technologies that align with market trends and consumer values. Embrace the opportunity to lead in this dynamic industry by prioritizing strategic sourcing practices that will drive growth and sustainability in your shoe manufacturing endeavors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to fabric for shoes