Introduction: Navigating the Global Market for custom leather branding iron

In the dynamic landscape of global commerce, sourcing custom leather branding irons presents a unique challenge for B2B buyers. As businesses across Africa, South America, the Middle East, and Europe seek to establish their brand identity through high-quality leather goods, understanding the nuances of branding iron options is essential. This guide delves into the intricate world of custom leather branding irons, exploring various types, applications, and crucial supplier vetting processes.

From fire-heated to electric branding irons, and from basic packages to those designed for specialized applications like curved surfaces, the choices can be overwhelming. Additionally, factors such as cost considerations, production timelines, and artwork requirements play a pivotal role in the decision-making process.

By leveraging this comprehensive resource, international buyers can navigate the complexities of sourcing custom leather branding irons with confidence. The insights provided here empower businesses to make informed purchasing decisions that enhance their branding efforts and ultimately contribute to their market competitiveness. Whether you’re a leather goods manufacturer in Vietnam or a craftsman in Germany, this guide serves as your roadmap to effectively integrating custom branding solutions into your product offerings.

Table Of Contents

- Top 5 Custom Leather Branding Iron Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather branding iron

- Understanding custom leather branding iron Types and Variations

- Key Industrial Applications of custom leather branding iron

- 3 Common User Pain Points for ‘custom leather branding iron’ & Their Solutions

- Strategic Material Selection Guide for custom leather branding iron

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather branding iron

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather branding iron’

- Comprehensive Cost and Pricing Analysis for custom leather branding iron Sourcing

- Alternatives Analysis: Comparing custom leather branding iron With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather branding iron

- Navigating Market Dynamics and Sourcing Trends in the custom leather branding iron Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather branding iron

- Strategic Sourcing Conclusion and Outlook for custom leather branding iron

- Important Disclaimer & Terms of Use

Understanding custom leather branding iron Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fire-Heated Branding Irons | Simple design, requires manual heating | Small-scale leather goods manufacturers | Pros: Cost-effective; Cons: Slower production speed. |

| Electric Branding Irons | Consistent heating, often with temperature control | Large-scale production and high-volume branding | Pros: Efficient; consistent results; Cons: Higher initial investment. |

| Custom Curved Surface Branders | Designed for uneven surfaces like sports balls | Sporting goods manufacturers | Pros: Versatile; can handle various shapes; Cons: Limited to specific applications. |

| Heavy Duty Branding Irons | Durable construction for thick materials | Heavy-duty leatherwork, industrial applications | Pros: Long-lasting; suitable for tough materials; Cons: Heavier and may require more effort to use. |

| Light Duty Branding Irons | Lightweight and portable, suitable for lighter materials | Crafting and hobbyist sectors | Pros: Easy to use; cost-effective; Cons: Not suitable for heavy-duty applications. |

What Are Fire-Heated Branding Irons and Their Applications?

Fire-heated branding irons are the most traditional type, relying on manual heating methods. These tools are typically made of metal and require a heat source, such as a flame or charcoal, to reach the necessary temperature for branding. They are particularly suited for small-scale leather goods manufacturers who may not need high-volume production. While they are cost-effective, the slower branding process and the need for constant reheating can be drawbacks for businesses aiming for efficiency.

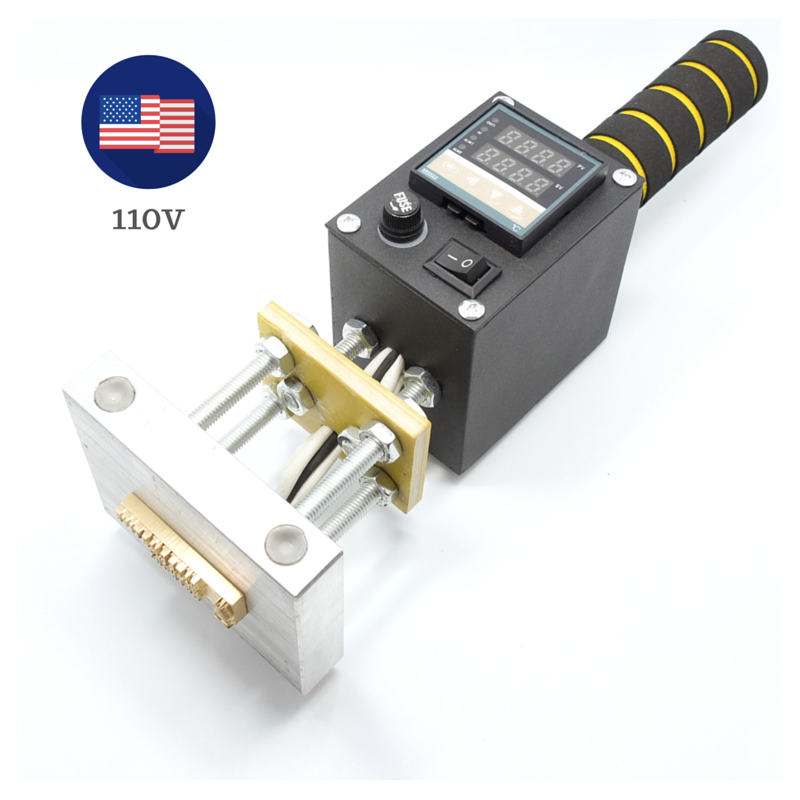

Illustrative image related to custom leather branding iron

How Do Electric Branding Irons Enhance Production?

Electric branding irons represent a modern advancement in branding technology. They provide consistent heating and often come with temperature control features, making them ideal for large-scale production and high-volume branding. This type is particularly beneficial for businesses in Europe and North America that prioritize efficiency and precision. Although the initial investment is higher than fire-heated options, the long-term benefits in productivity and quality can outweigh the costs.

What Makes Custom Curved Surface Branders Unique?

Custom curved surface branders are specifically designed to accommodate uneven surfaces, such as those found on sporting goods like basketballs. This versatility allows manufacturers in the sporting goods sector to apply branding effectively on a variety of shapes. While these tools can be more specialized, their ability to handle different materials and forms makes them invaluable for businesses focusing on unique product offerings. However, they may not be suitable for traditional flat leather branding tasks.

Why Choose Heavy Duty Branding Irons for Tough Materials?

Heavy-duty branding irons are constructed from durable materials to withstand the rigors of branding thick leathers and other tough materials. These tools are essential for industrial applications and businesses that require robust branding solutions. Their longevity and ability to handle demanding tasks make them a worthwhile investment. However, their weight and size can make them less convenient for smaller operations or those focusing on lighter materials.

What Are the Advantages of Light Duty Branding Irons?

Light duty branding irons are designed for portability and ease of use, making them ideal for crafting and hobbyist sectors. They are well-suited for lighter materials and small projects, offering a cost-effective solution for businesses just starting or those with lower branding demands. While they excel in usability and price, they may not meet the needs of companies requiring heavy-duty branding capabilities or high-volume output.

Illustrative image related to custom leather branding iron

Key Industrial Applications of custom leather branding iron

| Industry/Sector | Specific Application of custom leather branding iron | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Branding leather garments and accessories with logos | Enhances brand identity and customer loyalty | Consider heat settings for different leather types and design intricacies. |

| Furniture Manufacturing | Marking leather upholstery and furniture with company branding | Adds value and authenticity to products | Ensure durability and clarity of branding on textured surfaces. |

| Leather Goods Production | Custom branding of leather bags, wallets, and belts | Differentiates products in a competitive market | Look for irons that can handle varying thicknesses of leather. |

| Sports Equipment | Branding sports balls and gear, such as basketballs and gloves | Creates a professional look and promotes brand visibility | Evaluate the need for curved branding solutions for diverse items. |

| Craft and DIY Market | Personalization of leather goods for artisanal products | Attracts niche markets and enhances product appeal | Assess the customization options available for unique designs. |

How Is Custom Leather Branding Iron Used in the Fashion and Apparel Sector?

In the fashion and apparel industry, custom leather branding irons are utilized to imprint logos and designs onto leather garments and accessories. This process not only enhances brand identity but also fosters customer loyalty by providing a unique touch to products. For international buyers, especially from regions like Africa and Europe, it is essential to consider the type of leather being branded, as different materials require specific heat settings to achieve the best results without damaging the fabric.

What Role Does Custom Leather Branding Iron Play in Furniture Manufacturing?

In furniture manufacturing, custom leather branding irons are used to mark upholstery and leather-covered furniture with company logos. This branding adds authenticity and value to the products, distinguishing them in a crowded market. Buyers should focus on sourcing branding irons that can effectively handle the varying textures and thicknesses of leather used in furniture, ensuring that the branding is clear and durable over time.

How Can Leather Goods Producers Benefit from Custom Branding?

Leather goods producers leverage custom branding irons to personalize items such as bags, wallets, and belts. This branding not only differentiates their products but also caters to consumer demand for unique, customized goods. For B2B buyers, especially from South America and the Middle East, it is crucial to assess the branding iron’s capability to handle different leather types and sizes, ensuring the final product meets quality expectations.

What Are the Applications of Custom Branding in Sports Equipment?

In the sports equipment industry, custom leather branding irons are essential for branding items like basketballs and sports gloves. This branding creates a professional look while promoting brand visibility among consumers. Buyers should consider sourcing solutions that accommodate curved surfaces, as many sports items require specialized branding techniques to ensure the logo fits seamlessly on the product.

How Does Custom Leather Branding Iron Enhance the Craft and DIY Market?

In the craft and DIY market, custom leather branding irons are used for personalizing artisanal leather goods. This personalization attracts niche markets and enhances the overall appeal of products. For international buyers, it is important to evaluate the customization options available, including the ability to create unique designs that resonate with local consumer preferences, thereby maximizing market reach.

3 Common User Pain Points for ‘custom leather branding iron’ & Their Solutions

Scenario 1: Inconsistent Branding Quality Across Different Leather Types

The Problem: B2B buyers often face the challenge of achieving consistent branding quality when working with various types of leather. Different leather grades, such as soft leather versus thick leather, require different heat settings and dwell times. This inconsistency can lead to uneven branding, where some products look professional while others appear poorly marked, risking brand reputation and customer satisfaction. Buyers may find it difficult to determine the right settings for each leather type, leading to wasted materials and time.

The Solution: To overcome this issue, buyers should invest in electric branding irons equipped with digital temperature control. These tools allow precise adjustments based on the leather type, ensuring consistent branding results. Additionally, conducting small test runs on scraps of each leather type before full-scale production can help determine the optimal heat settings and dwell times. Providing detailed training to staff on the specific requirements for different leather types will further enhance branding quality. Suppliers can also provide guidance on best practices, which should be leveraged during the sourcing process to ensure all team members are aligned on branding techniques.

Scenario 2: Long Lead Times for Custom Branding Irons

The Problem: Many B2B buyers encounter long lead times when ordering custom branding irons, which can hinder production schedules and delay product launches. This is especially problematic for businesses that operate on tight timelines or seasonal cycles. If a buyer needs a unique logo or design, the standard production times, often two weeks or more, can result in missed deadlines and lost sales opportunities.

The Solution: To mitigate lead time issues, buyers should establish relationships with multiple suppliers who offer expedited services for custom branding irons. When placing orders, it’s advisable to inquire about rush processing options and prioritize designs that can be manufactured quickly. Buyers should also maintain a well-defined inventory of commonly used branding irons to reduce the need for custom orders. Additionally, utilizing a branding iron design generator, which allows for quick modifications, can save time and help streamline the production process. By planning ahead and diversifying suppliers, buyers can better navigate lead time challenges.

Scenario 3: High Initial Investment with Uncertain ROI

The Problem: Investing in custom leather branding irons often requires a significant upfront cost, which can be daunting for businesses, particularly small to medium-sized enterprises. The uncertainty regarding the return on investment (ROI) can cause hesitation, especially if the branding process is new to the business. Buyers may worry about whether they will be able to generate enough demand to justify the expense or if the branding quality will meet their expectations.

The Solution: To ensure a positive ROI, buyers should conduct thorough market research to assess demand for branded products in their target market. Engaging with existing customers to gauge interest in branded items can provide valuable insights. Additionally, buyers can start with a smaller, high-quality branding iron tailored to their most popular products, allowing them to test the waters before committing to larger orders. Offering introductory discounts or limited-time promotions on branded products can also stimulate interest and drive sales. Tracking performance metrics post-launch will help buyers evaluate the effectiveness of their branding strategy and adjust accordingly, ensuring that the investment yields profitable returns over time.

Strategic Material Selection Guide for custom leather branding iron

What Materials Are Commonly Used for Custom Leather Branding Irons?

When selecting materials for custom leather branding irons, several factors come into play, including thermal properties, durability, manufacturing complexity, and cost. Below, we analyze four common materials used in the production of branding irons: brass, stainless steel, aluminum, and copper. Each material has its unique characteristics that can significantly impact the branding process and the final product.

How Does Brass Perform as a Material for Branding Irons?

Brass is a popular choice for branding irons due to its excellent thermal conductivity, allowing for even heat distribution. This property ensures that the branding iron reaches the necessary temperature quickly and maintains it, which is crucial for effective branding on various leather types. Brass is also resistant to corrosion, which enhances its longevity.

Illustrative image related to custom leather branding iron

Pros: Brass branding irons are durable and can withstand high temperatures without warping. They are relatively easy to machine, allowing for intricate designs and detailed logos.

Cons: The primary drawback of brass is its cost, which can be higher than other materials. Additionally, brass can tarnish over time, requiring maintenance to keep the branding iron looking its best.

Impact on Application: Brass is suitable for branding on soft and firm leather, making it versatile for different applications. However, users must consider the need for regular cleaning to maintain branding quality.

What Are the Advantages of Stainless Steel for Branding Irons?

Stainless steel is another commonly used material for branding irons, known for its strength and corrosion resistance. It can withstand extreme temperatures and is less prone to warping compared to softer metals.

Pros: The durability of stainless steel makes it ideal for high-volume branding operations. It requires minimal maintenance and can be easily cleaned, ensuring consistent branding quality.

Illustrative image related to custom leather branding iron

Cons: The manufacturing complexity of stainless steel branding irons can be higher, leading to increased costs. Additionally, stainless steel has lower thermal conductivity than brass, which may require longer heating times.

Impact on Application: Stainless steel branding irons are suitable for various leather types, including thick and firm leather. However, they may not be the best choice for intricate designs due to potential limitations in detail.

How Does Aluminum Compare as a Material for Branding Irons?

Aluminum is lightweight and has good thermal conductivity, making it a suitable option for branding irons. It is often used in applications where weight is a concern, such as portable branding tools.

Pros: Aluminum branding irons are generally less expensive to manufacture and are easy to handle due to their lightweight nature. They heat up quickly, allowing for efficient branding.

Cons: The primary disadvantage of aluminum is its lower durability compared to brass and stainless steel. It can warp under high temperatures and may not be suitable for heavy-duty applications.

Impact on Application: Aluminum is best for branding on softer leathers and can be used for promotional items. However, it may not perform well in high-volume settings or with intricate designs.

What Role Does Copper Play in Branding Irons?

Copper is known for its excellent thermal conductivity, making it an effective material for branding irons. It heats up quickly and retains heat well, which is essential for consistent branding.

Pros: Copper branding irons can achieve high-quality branding results due to their ability to maintain temperature. They are also relatively easy to machine, allowing for customized designs.

Illustrative image related to custom leather branding iron

Cons: The main downside of copper is its susceptibility to corrosion, requiring regular maintenance to prevent tarnishing. Additionally, it can be more expensive than other materials.

Impact on Application: Copper is suitable for branding on various leather types, but its maintenance needs may deter some users. It is ideal for high-quality branding where detail and precision are paramount.

Summary Table of Material Selection for Custom Leather Branding Irons

| المواد | Typical Use Case for custom leather branding iron | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General leather branding | Excellent thermal conductivity | Higher cost and requires maintenance | عالية |

| Stainless Steel | High-volume branding operations | Durable and corrosion-resistant | Higher manufacturing complexity | Medium |

| Aluminum | Lightweight, portable branding tools | Lightweight and cost-effective | Less durable, prone to warping | منخفضة |

| Copper | High-quality branding with intricate designs | Maintains temperature well | Susceptible to corrosion, requires upkeep | Medium |

This guide provides B2B buyers with a comprehensive understanding of the material options available for custom leather branding irons. By considering the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their branding needs and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather branding iron

What Are the Key Stages in the Manufacturing Process of Custom Leather Branding Irons?

The manufacturing process of custom leather branding irons involves several critical stages that ensure the final product meets the specific requirements of B2B buyers. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to custom leather branding iron

-

Material Preparation: The first step involves selecting high-quality materials, typically brass or stainless steel, known for their durability and heat retention properties. The chosen material is cut into the desired shape and size, ensuring it meets the specifications provided by the customer. This stage is crucial as the quality of the raw materials directly affects the performance and longevity of the branding irons.

-

Forming: In this stage, the branding heads are formed using CNC machining or traditional engraving techniques. CNC machines offer precision in creating intricate designs and logos, which are essential for branding. The depth of the engraving is critical, as a deeper relief allows for better branding on varied surfaces, including textured leather.

-

Assembly: Once the branding heads are formed, they are assembled with handles, which can be wooden or metallic, depending on the design preferences. The assembly process ensures that all components fit securely, providing ease of use during the branding process. For electric branding irons, this stage includes integrating heating elements and electrical components, ensuring they operate efficiently and safely.

-

Finishing: The final stage involves polishing and coating the branding irons to enhance their appearance and protect against corrosion. This may include applying protective coatings or finishes that not only add aesthetic value but also improve functionality. Quality checks during this stage ensure that the branding irons are free from defects and meet the specified standards.

How is Quality Assurance Implemented in Custom Leather Branding Iron Production?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the branding irons produced meet international standards and customer expectations.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 standards, which provide a framework for quality management systems. Compliance with these standards assures B2B buyers that the products are manufactured consistently and meet the necessary quality benchmarks. Other certifications, such as CE marking for products sold in Europe or API for those in the oil and gas sector, may also apply depending on the specific application of the branding irons.

-

Quality Control Checkpoints: The QA process typically includes several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted to monitor the quality of the work in progress. This includes checking the precision of engravings and the integrity of assembled components.

– Final Quality Control (FQC): Before shipping, each branding iron undergoes a final inspection to ensure it meets all specifications and quality standards. This may include functional tests to verify heating performance and brand clarity. -

Common Testing Methods: Testing methods can vary depending on the type of branding iron but may include thermal tests to ensure that electric branding irons reach the required temperatures efficiently. Additionally, visual inspections for any defects or inconsistencies in engraving quality are standard practices.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control procedures is crucial. Here are several strategies:

-

Supplier Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insights into their quality control processes. This includes examining their compliance with international standards and reviewing their quality management systems.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including records of inspections and tests conducted. These reports should detail the methods used and the results, giving buyers confidence in the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an additional layer of verification. These agencies can perform independent assessments of the manufacturing process and product quality, ensuring that the branding irons meet both international standards and specific buyer requirements.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control can present unique challenges for international B2B buyers. Here are some nuances to consider:

-

Cultural and Regulatory Differences: Different regions may have varying standards for product quality and safety. Buyers should familiarize themselves with the specific regulations and standards applicable in their region to ensure compliance.

-

Communication Barriers: Language differences can complicate the understanding of quality control processes. It is essential for buyers to establish clear communication channels with suppliers, potentially involving bilingual staff or translators when necessary.

-

Logistical Considerations: International shipping can introduce additional risks to product quality. Buyers should discuss packaging and handling procedures with suppliers to mitigate any potential damage during transit.

الخاتمة

Understanding the manufacturing processes and quality assurance measures for custom leather branding irons is essential for international B2B buyers. By familiarizing themselves with the key stages of production, quality control checkpoints, and verification methods, buyers can make informed decisions when selecting suppliers. This knowledge not only enhances the likelihood of acquiring high-quality branding irons but also fosters long-term partnerships with reliable manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather branding iron’

In the pursuit of acquiring a custom leather branding iron, it’s essential to follow a structured approach to ensure you make informed decisions. This guide provides a step-by-step checklist to help B2B buyers navigate the sourcing process effectively.

Illustrative image related to custom leather branding iron

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clarify your branding needs. Consider the type of leather you will be branding, the size and shape of the branding iron, and the intricacy of your design.

– Material Requirements: Determine if you need brass, steel, or another material based on durability and heat retention.

– Design Complexity: Assess whether you need simple text or intricate logos, as this will influence manufacturing choices.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in custom branding irons. Utilize online directories, industry forums, and trade shows to gather information.

– Supplier Reviews: Look for feedback from previous customers to gauge reliability and product quality.

– Portfolio Examination: Review their previous work to ensure their capabilities align with your design requirements.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO or CE marks, which indicate compliance with industry standards.

– Quality Assurance: Certifications often reflect a commitment to quality and safety, crucial for long-term partnerships.

– Sustainability Practices: Consider suppliers who adhere to environmentally friendly practices, which can be beneficial for your brand image.

Step 4: Request Samples

Before placing a bulk order, request samples of the branding irons to evaluate quality and performance. This step is critical to ensure that the product meets your expectations.

– Test Branding: Use the samples on different leather types to assess heat application and clarity of the branding.

– Durability Check: Examine the samples for wear and tear to ensure they can withstand repeated use.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures, including any volume discounts and payment terms. Understanding these elements upfront can prevent future disputes.

– Hidden Costs: Inquire about additional fees such as shipping, customs, or setup charges.

– Flexible Payment Options: Look for suppliers that offer favorable payment terms, which can help manage cash flow.

Illustrative image related to custom leather branding iron

Step 6: Negotiate Lead Times

Clarify production lead times and ensure they align with your project timeline. Timely delivery is essential for meeting customer demands and maintaining your production schedule.

– الطاقة الإنتاجية: Ensure the supplier can handle your order size within the required timeframe.

– Contingency Plans: Discuss options for expedited orders in case of urgent needs.

Step 7: Finalize the Contract

Once you have selected a supplier, finalize the terms in a detailed contract. This contract should outline all agreed-upon specifications, pricing, lead times, and quality assurances.

– Clear Terms: Ensure the contract includes clauses for quality control, dispute resolution, and delivery schedules.

– Sign-Off Process: Establish a clear process for approvals to streamline communication and avoid misunderstandings.

By following these steps, B2B buyers can effectively source custom leather branding irons that meet their specific needs, ensuring a smooth procurement process and high-quality branding results.

Illustrative image related to custom leather branding iron

Comprehensive Cost and Pricing Analysis for custom leather branding iron Sourcing

What Are the Key Cost Components for Custom Leather Branding Irons?

When sourcing custom leather branding irons, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Brass is commonly used for its durability and heat retention, while stainless steel may be preferred for its corrosion resistance. The gauge and quality of the metal also determine the overall cost.

-

Labor: Labor costs can vary depending on the complexity of the design and the level of customization required. Skilled artisans may be needed for intricate engravings, which can drive up costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help minimize overhead, making it a critical factor in pricing.

-

Tooling: Custom branding irons often require specialized tooling for unique designs. This upfront investment can be substantial, especially for intricate logos or patterns, and is typically factored into the overall pricing.

-

Quality Control (QC): Ensuring the branding irons meet specific quality standards involves additional costs. Rigorous testing and inspection processes are necessary, particularly for products intended for international markets.

-

Logistics: Shipping costs can be significant, especially for international buyers. Factors such as distance, weight, and shipping method will influence the final price.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This can vary widely depending on the supplier’s business model and market competition.

What Factors Influence Pricing for Custom Leather Branding Irons?

Several key factors can influence the pricing of custom leather branding irons:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order volume. Larger orders usually result in lower per-unit costs, making it advantageous for businesses to consolidate their purchases.

-

Specifications and Customization: The complexity of the design directly affects the cost. Simple text branding is generally less expensive than intricate logos that require deeper engraving.

-

Material Quality and Certifications: Higher-quality materials and those with certifications (e.g., for environmental compliance) may come at a premium. Buyers should assess the long-term value of investing in higher-quality products.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms determine the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total cost.

What Negotiation Tips Can Help Achieve Cost-Efficiency?

Effective negotiation can lead to better pricing and cost-efficiency for B2B buyers:

-

Establish Clear Requirements: Providing detailed specifications upfront can prevent misunderstandings and ensure accurate quotes.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQ thresholds that qualify for discounts.

-

Explore Alternative Suppliers: Comparing multiple suppliers can provide leverage in negotiations and help identify the best value for your needs.

-

Discuss Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce financial strain.

-

Consider Total Cost of Ownership (TCO): Analyze not just the initial purchase price but also long-term costs associated with maintenance, durability, and potential replacements.

What Are the Pricing Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are specific pricing nuances to consider:

-

Currency Fluctuations: Be aware of exchange rates and their potential impact on overall costs. Locking in prices at the time of order can mitigate risks.

-

Import Duties and Taxes: Research the import duties and taxes applicable in your country, as these can significantly increase the total landed cost.

-

Shipping and Handling: Choose shipping options that balance speed and cost. Delays in shipping can lead to unexpected expenses, especially for time-sensitive projects.

-

Cultural Considerations: Understand cultural differences in negotiation styles and business practices, which can affect the purchasing process.

-

Regulatory Compliance: Ensure that the branding irons comply with local regulations, particularly regarding materials and safety standards, to avoid costly fines or product recalls.

By carefully considering these cost components, price influencers, and negotiation strategies, B2B buyers can make informed decisions when sourcing custom leather branding irons, ultimately achieving better value for their investments.

Alternatives Analysis: Comparing custom leather branding iron With Other Solutions

When considering branding solutions for leather products, businesses often explore various methods to achieve high-quality, lasting results. While custom leather branding irons are a popular choice, several alternative technologies and methods can also effectively meet branding needs. This section provides a comprehensive comparison of custom leather branding irons against other viable solutions, helping B2B buyers make informed decisions.

| Comparison Aspect | Custom Leather Branding Iron | Electric Branding Iron | Laser Engraving System |

|---|---|---|---|

| Performance | Excellent heat retention; clear marks on leather | Consistent heat; suitable for high volume | High precision; can engrave intricate designs |

| Cost | Moderate ($89 – $300) | Higher ($300 – $500) | Highest ($1,000+) |

| Ease of Implementation | Requires manual heating | Plug-and-play; easy to use | Requires technical setup; software knowledge needed |

| Maintenance | Low; periodic cleaning needed | Low; minimal upkeep | Moderate; software updates and maintenance required |

| Best Use Case | Small to medium runs; artisanal branding | High-volume production; consistent branding | Complex designs; high-end products |

What are the Pros and Cons of Electric Branding Irons?

Electric branding irons offer a modern alternative to traditional fire-heated branding methods. They provide consistent heat, making them ideal for high-volume branding needs. The ease of use, with a simple plug-and-play setup, allows for quick transitions between projects. However, the initial investment is higher than that of custom leather branding irons, and they may lack the artisanal feel that some businesses desire. Additionally, while they are effective for branding leather, their performance on other materials may vary.

Illustrative image related to custom leather branding iron

How Does Laser Engraving Compare to Custom Leather Branding Irons?

Laser engraving systems represent a high-tech solution for branding that delivers exceptional precision and versatility. They can engrave intricate designs and logos onto leather and other materials with remarkable detail, making them ideal for high-end products. However, this technology comes with a significantly higher price tag and requires a more complex setup, including software for design input. Maintenance can also be more demanding, as it involves software updates and regular hardware checks. For businesses focusing on intricate, detailed branding, laser engraving may be worth the investment despite the higher costs.

Conclusion: How to Choose the Right Branding Solution for Your Needs

Selecting the appropriate branding method depends on various factors, including the scale of production, budget constraints, and the desired branding quality. For businesses looking for an artisanal approach with moderate costs, custom leather branding irons remain an excellent choice. Conversely, for high-volume production with a need for consistency, electric branding irons may be more suitable. Finally, if intricate designs are a priority and budget permits, laser engraving systems offer unparalleled precision. B2B buyers should assess their specific branding requirements and operational capabilities to determine the best solution for their leather branding needs.

Essential Technical Properties and Trade Terminology for custom leather branding iron

What Are the Key Technical Properties of Custom Leather Branding Irons?

When selecting a custom leather branding iron, understanding its technical properties is crucial for ensuring quality and efficiency in branding operations. Here are several key specifications:

-

Material Grade

Custom branding irons are typically crafted from high-grade materials such as brass or stainless steel. Brass is favored for its excellent heat retention and durability, while stainless steel offers superior corrosion resistance. The choice of material impacts the longevity of the branding iron and the quality of the branded mark on leather. -

Size and Dimensions

Branding irons come in various sizes, commonly ranging from 1″ x 1″ to 2″ x 2″ or larger. The size affects the visibility of the branded design and is essential for branding items of different dimensions. A larger branding head may be suitable for bigger leather goods, while smaller sizes are ideal for delicate items. -

Heating Method

Branding irons can be fire-heated or electric. Electric branding irons provide consistent temperature control, which is vital for achieving clean, precise marks. Fire-heated irons, while traditional, may require more skill to maintain the correct temperature, particularly when working with various leather types. -

Temperature Control

Effective branding requires specific temperature settings based on the leather type. A branding iron with adjustable temperature controls allows for versatile use across different leather grades. This feature is particularly beneficial for businesses that handle a variety of leather products, as it helps prevent damage to the material. -

Relief Depth

The depth of engraving on the branding head, usually between 0.1” to 0.15”, determines the clarity and quality of the brand. A deeper relief is particularly effective for uneven surfaces and ensures that the design is well-defined on the leather, enhancing the product’s branding impact. -

Dwell Time

Dwell time refers to the duration the branding iron is in contact with the leather. This factor is critical as it influences the quality of the imprint. Different leather types require different dwell times; understanding this can help in optimizing branding processes for efficiency and quality.

Which Trade Terminology Should B2B Buyers Understand When Purchasing Custom Leather Branding Irons?

Navigating the procurement of custom branding irons involves understanding essential trade terms that can impact transactions and supply chain processes:

Illustrative image related to custom leather branding iron

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that may be marketed under another brand. Understanding OEM relationships is crucial for buyers seeking custom branding solutions, as it can influence product quality and customization options. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to produce or sell. This term is significant for B2B buyers as it affects inventory management and budgeting, especially when considering bulk purchases for branding operations. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. Utilizing RFQs can help buyers compare costs and negotiate better deals, ensuring they receive the best value for custom branding irons. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for understanding shipping costs, risks, and obligations in cross-border trade. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the goods. Knowing lead times is essential for B2B buyers as it affects inventory levels and production schedules, especially when time-sensitive branding projects are involved. -

Customization Options

This refers to the various ways in which branding irons can be tailored to meet specific branding needs, including size, design, and heating method. Understanding customization options allows buyers to align their branding strategies with their product offerings effectively.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing custom leather branding irons, ensuring they select products that meet their specific branding needs while optimizing their operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the custom leather branding iron Sector

What Are the Current Trends and Dynamics in the Custom Leather Branding Iron Market?

The global market for custom leather branding irons is witnessing significant evolution, driven by the increasing demand for personalized branding in various sectors, including fashion, crafts, and industrial applications. B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking unique branding solutions that can enhance product differentiation and customer engagement. The rise of e-commerce and online customization tools has enabled businesses to offer tailored branding options, allowing buyers to create distinctive designs that resonate with their target audiences.

Emerging technologies, such as electric branding irons with digital temperature controls, are transforming the branding process, making it more efficient and consistent. This innovation reduces the learning curve for new users and enhances production capabilities for high-volume operations. Additionally, the integration of CAD software in the design phase enables manufacturers to produce complex logos and designs with precision, meeting the specific needs of diverse markets.

Moreover, sustainability is becoming a pivotal factor in sourcing decisions. Buyers are increasingly concerned about the environmental impact of their branding practices, prompting suppliers to adopt more sustainable materials and production processes. As a result, the market is shifting towards eco-friendly branding solutions, which not only align with corporate social responsibility goals but also appeal to environmentally conscious consumers.

How Is Sustainability Reshaping the Custom Leather Branding Iron Industry?

The custom leather branding iron sector is at a crossroads where sustainability and ethical sourcing are becoming essential considerations for B2B buyers. The environmental impact of leather production, including deforestation, water usage, and chemical pollution, has raised awareness about the importance of responsible sourcing. As a result, businesses are prioritizing suppliers who demonstrate a commitment to sustainable practices.

Illustrative image related to custom leather branding iron

Sustainable branding irons are increasingly made from eco-friendly materials, such as recycled metals and sustainably sourced brass. Additionally, manufacturers are implementing energy-efficient production techniques, reducing waste, and minimizing their carbon footprint. Certifications such as Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are becoming vital indicators for buyers seeking to ensure that their branding irons are produced in environmentally responsible ways.

For B2B buyers, partnering with suppliers who prioritize ethical sourcing not only enhances their brand image but also helps build consumer trust. As the market continues to evolve, businesses that align their branding practices with sustainability principles will likely gain a competitive edge in the global marketplace.

How Has the Custom Leather Branding Iron Market Evolved Over Time?

The history of custom leather branding irons dates back centuries, originating as tools for marking ownership on livestock. Over time, these tools have evolved significantly, transitioning from simple, manual designs to sophisticated, customizable branding solutions that cater to diverse industries. The advent of industrialization in the 19th century brought about mass production techniques, allowing for the widespread use of branding irons in various sectors, including leather goods and crafts.

In the contemporary landscape, the introduction of electric branding irons and advanced engraving technologies has revolutionized the market. These innovations enable precise and consistent branding, catering to the growing demand for personalization and customization. As global trade expands, the accessibility of high-quality branding irons has increased, allowing international B2B buyers to enhance their branding capabilities and meet the unique needs of their customers.

Understanding this evolution not only highlights the rich history of branding tools but also underscores the market’s adaptability to changing consumer demands and technological advancements, providing valuable insights for B2B buyers looking to invest in custom leather branding solutions.

Illustrative image related to custom leather branding iron

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather branding iron

-

How can I ensure high-quality custom leather branding irons?

To guarantee high-quality branding irons, research suppliers with a solid reputation in the industry. Request samples to evaluate the craftsmanship and material quality. It’s essential to check if they use durable materials, such as brass or steel, which retain heat effectively. Additionally, inquire about the manufacturing process, including any quality assurance measures they implement. Look for suppliers who provide detailed specifications and clear images of their products. Reading customer reviews and testimonials can also provide insights into their reliability and product performance. -

What customization options are available for branding irons?

Most suppliers offer a variety of customization options for branding irons, including size, shape, and design. You can typically personalize branding irons with your logo, text, or artwork. Ensure to provide high-resolution images or vector files for best results. Ask about the depth and relief of the engraving, as this affects how well the design appears on the leather. Suppliers may also offer different heating methods, such as electric or fire-heated options, which can be tailored to your branding needs. -

What are the minimum order quantities (MOQs) for custom branding irons?

Minimum order quantities can vary significantly among suppliers, often depending on the complexity of the design and materials used. Some manufacturers may require a MOQ of 10-50 units for custom branding irons, while others may be more flexible, especially for repeat customers. When sourcing, clarify the MOQ with potential suppliers early in the conversation. If you’re testing a new design or brand, consider suppliers who offer lower MOQs to minimize financial risk. -

What payment terms should I expect when purchasing branding irons internationally?

Payment terms can vary by supplier and location, but common practices include upfront payments, partial payments, or net terms (e.g., net 30 or net 60). Ensure you discuss payment methods accepted, such as bank transfers, credit cards, or payment platforms like PayPal. When dealing with international purchases, consider potential currency fluctuations and transaction fees. It’s advisable to establish a clear contract that outlines payment terms, delivery schedules, and any penalties for late payments to avoid misunderstandings. -

How do I verify the credibility of a supplier for branding irons?

Verifying a supplier’s credibility involves multiple steps. Start by checking their business registration and certifications to ensure they are a legitimate entity. Look for reviews or testimonials from other B2B clients, and consider reaching out to them for feedback. Request references and check their experience in manufacturing custom branding irons. Additionally, assess their communication responsiveness and willingness to provide detailed information about their products and processes, as these are indicators of a reliable supplier. -

What logistics considerations should I keep in mind when sourcing branding irons?

When sourcing branding irons internationally, consider shipping costs, delivery timelines, and customs regulations. Inquire about the supplier’s shipping methods and whether they handle customs clearance or if you need to manage it yourself. Understanding the import duties and taxes applicable in your country can help you budget more accurately. Additionally, choose a supplier who provides tracking information to monitor your shipment’s progress, ensuring you receive your order on time. -

What quality assurance practices should I expect from a branding iron supplier?

A reputable branding iron supplier should have established quality assurance practices in place. Ask about their inspection processes during production, including material checks and final product inspections. They should also provide guarantees for their products, such as the durability of the branding and resistance to wear over time. Inquire whether they have a return or replacement policy in case the products do not meet agreed-upon specifications, as this reflects their commitment to quality. -

How can I ensure the branding process is effective on different leather types?

Different leather types require varying branding techniques and heat levels. When sourcing branding irons, ask suppliers for guidance on the best practices for branding specific leather types, including soft, firm, or textured leather. They should provide recommendations on ideal temperatures and dwell times for effective branding. Additionally, consider investing in an electric branding tool with temperature control features to achieve consistent results. Testing on sample pieces before full production can also help you fine-tune the process for optimal branding outcomes.

Top 5 Custom Leather Branding Iron Manufacturers & Suppliers List

1. Branding Irons – Custom & Livestock Solutions

Domain: brandingirons.com

Registered: 1999 (26 years)

مقدمة: Branding Irons for Leather – Family owned and operated for over 25 years. Made in the USA. Custom Branding Iron Quote, Livestock Branding Irons, Curved Custom Branding Iron, Extra Large Custom Branding Irons, Custom Interchangeable Branding Irons, Light Duty Branding Irons, Heavy Duty Branding Irons, Basic Pre-Made Packages, Personalized Branding Irons, Food Branding Irons, Event Planning & Cateri…

2. LW Leathers – Electric Branding Irons

Domain: lwleathers.com

Registered: 2012 (13 years)

مقدمة: Electric Branding Iron for leather stamping with custom leather stamp & Gold Foiling. Production lead time: 2-5 working days. Collection includes 4 types of electric branding irons: 60W heat embosser for vegetable tanned leather (stamps up to 4x4cm), 300W electric branding iron with digital control for stamps up to 6x6cm (works with chrome tanned and faux leather), 500W electric branding iron for …

3. Leather Branding Tool – Custom Logo Stamps

Domain: reddit.com

Registered: 2005 (20 years)

مقدمة: Ordering leather branding tool; searching for one with a logo on Etsy; concerns about supporting local businesses; mention of 80 watt heating irons from Leatherstampmaker.com; custom logo stamps available.

4. Custom Branding Irons – Fast Shipping & No Setup Fee

Domain: custombrandshop.com

Registered: 2016 (9 years)

مقدمة: This company, Custom Branding Irons – Fast Shipping & No Setup Fee, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

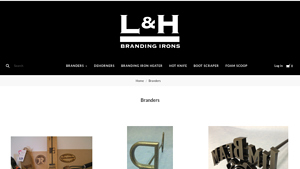

5. Custom Branding Irons – Key Products

Domain: lhbrandingirons.com

Registered: 1999 (26 years)

مقدمة: [{‘name’: ‘Custom Electric Wood Branding Irons’, ‘price’: ‘$240.00’, ‘description’: ‘Custom made branding irons to fit your design specifications. Designed to brand anything that will burn excluding live animals.’}, {‘name’: ‘Individual Character Paint Branding Irons’, ‘price’: ‘$54.00’, ‘description’: ‘For marking sale animals and paint branding sheep. Made of high quality aluminum, light in weig…

Strategic Sourcing Conclusion and Outlook for custom leather branding iron

In the competitive landscape of custom leather branding, strategic sourcing plays a pivotal role in securing quality products that enhance brand identity. By investing in high-quality branding irons—whether fire-heated or electric—businesses can ensure consistent and professional branding across various leather goods. Factors such as material durability, engraving precision, and temperature control are essential when selecting suppliers, particularly for international buyers from Africa, South America, the Middle East, and Europe.

Leveraging established suppliers who offer customization options can lead to unique branding solutions that resonate with target markets. For instance, deep relief branding irons are ideal for uneven surfaces, while electric models provide efficiency for high-volume production. Furthermore, understanding the nuances of heat application for different leather types can significantly impact the quality of the final product.

As you look to elevate your leather branding capabilities, consider the future of your sourcing strategy. Embrace innovation and customization to stay ahead in the market. Connect with reliable suppliers today to explore tailored solutions that not only meet your branding needs but also enhance your overall business offerings. The potential for growth and differentiation in your products awaits.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.