Introduction: Navigating the Global Market for shoe fabric

In an increasingly competitive landscape, sourcing high-quality shoe fabric that meets diverse market needs can pose a significant challenge for international B2B buyers. With a multitude of options available, including various fiber types, weaves, and treatments, selecting the right material is crucial for ensuring product quality and customer satisfaction. This guide serves as a comprehensive resource, covering essential aspects of shoe fabric, from types and applications to supplier vetting and cost considerations.

By delving into the intricacies of fabric characteristics—such as thread size, fiber composition, and surface treatments—buyers will gain insights into how these factors influence performance, durability, and aesthetics. Additionally, we will explore the nuances of regional preferences and regulations affecting the shoe fabric market, particularly for buyers from Africa, South America, the Middle East, and Europe, including key manufacturing hubs like Vietnam and Germany.

Equipped with this knowledge, B2B buyers can make informed purchasing decisions that not only enhance their product offerings but also optimize their supply chain management. Whether you are looking to innovate your design or streamline your sourcing strategy, this guide is designed to empower you with the expertise needed to navigate the complexities of the global shoe fabric market effectively.

Table Of Contents

- Top 7 Shoe Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for shoe fabric

- Understanding shoe fabric Types and Variations

- Key Industrial Applications of shoe fabric

- 3 Common User Pain Points for ‘shoe fabric’ & Their Solutions

- Strategic Material Selection Guide for shoe fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for shoe fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoe fabric’

- Comprehensive Cost and Pricing Analysis for shoe fabric Sourcing

- Alternatives Analysis: Comparing shoe fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for shoe fabric

- Navigating Market Dynamics and Sourcing Trends in the shoe fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoe fabric

- Strategic Sourcing Conclusion and Outlook for shoe fabric

- Important Disclaimer & Terms of Use

Understanding shoe fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyester | Durable, lightweight, quick-drying; UV resistant | Athletic footwear, casual shoes | Pros: Cost-effective, versatile. Cons: Less breathable than natural fibers. |

| Nylon | High tensile strength, abrasion-resistant, elastic | Outdoor and performance footwear | Pros: Strong and durable. Cons: Can retain heat, less eco-friendly. |

| Cotton Canvas | Natural fiber, breathable, customizable finishes | Casual and vulcanized shoes | Pros: Eco-friendly, easy to dye. Cons: Less water-resistant, may require special treatments. |

| Lycra | Highly elastic, stretchable, often blended | Sports and performance footwear | Pros: Excellent fit and comfort. Cons: Limited durability on its own. |

| Mesh | Lightweight, breathable, often moisture-wicking | Athletic shoes, casual footwear | Pros: Great ventilation, lightweight. Cons: Less support, can wear out quickly. |

What Are the Key Characteristics of Polyester in Shoe Fabric?

Polyester is a synthetic fabric known for its durability and lightweight nature, making it a popular choice for athletic and casual footwear. Its quick-drying properties and resistance to UV rays enhance its functionality, especially in outdoor applications. For B2B buyers, polyester offers cost-effectiveness and versatility, but it is essential to consider that it may not provide the same breathability as natural fibers, potentially impacting comfort in warmer climates.

How Does Nylon Stand Out in Footwear Fabrics?

Nylon is recognized for its high tensile strength and abrasion resistance, making it ideal for outdoor and performance footwear. Its elastic properties allow for flexibility and comfort, catering to active consumers. When purchasing nylon-based materials, B2B buyers should note that while nylon is robust, it can retain heat, which may be a drawback in warmer regions. Additionally, environmental considerations regarding the sustainability of nylon production are increasingly relevant.

Why Choose Cotton Canvas for Shoe Manufacturing?

Cotton canvas is a natural fiber that offers breathability and a range of customizable finishes, making it suitable for casual and vulcanized shoes. Its eco-friendly nature appeals to environmentally-conscious brands. Buyers should consider that while cotton canvas can be treated for water resistance, it typically requires additional finishing processes. This can add to manufacturing costs and time, so assessing the overall production timeline is crucial for B2B buyers.

What Advantages Does Lycra Provide in Shoe Fabrics?

Lycra, known for its exceptional stretchability, is frequently blended with other materials to enhance fit and comfort in sports and performance footwear. Its elasticity allows shoes to conform to the foot’s shape, promoting a snug fit. However, B2B buyers should be aware that Lycra on its own may not offer long-term durability, necessitating the use of blended fabrics for enhanced performance. Understanding the balance between comfort and longevity is key when sourcing Lycra materials.

How Does Mesh Fabric Enhance Shoe Performance?

Mesh fabric is characterized by its lightweight and breathable qualities, making it a favored choice for athletic and casual footwear. Its moisture-wicking properties help keep feet dry during physical activities, contributing to overall comfort. For B2B buyers, while mesh offers excellent ventilation, it may lack the structural support found in denser materials. Therefore, evaluating the specific application and target market is essential when considering mesh for shoe designs.

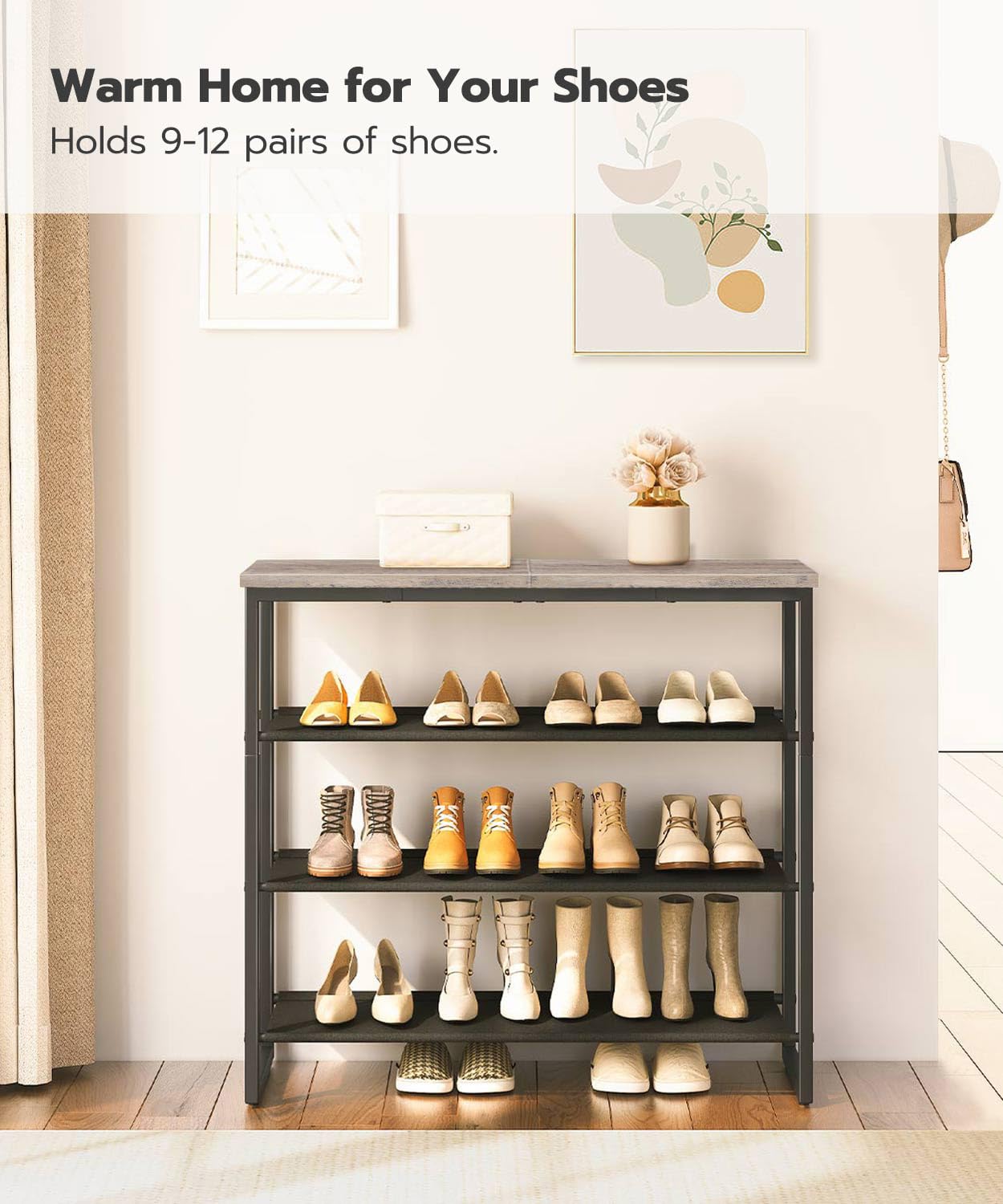

Key Industrial Applications of shoe fabric

| Industry/Sector | Specific Application of shoe fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Uppers for athletic and casual shoes | Enhances product performance and consumer appeal | Fabric durability, breathability, and weight specifications |

| Safety and Workwear | Protective footwear components | Ensures safety compliance and worker comfort | Flame resistance, waterproofing, and abrasion resistance |

| Fashion and Retail | Fashion-forward shoe designs | Differentiates brand offerings and attracts customers | Trend alignment, color variety, and texture options |

| Sports and Outdoor Gear | Specialized footwear for sports activities | Improves performance and reduces injury risk | Moisture-wicking properties, flexibility, and grip |

| Medical and Orthopedic | Custom shoe inserts and orthopedic footwear | Enhances patient mobility and comfort | Biocompatibility, cushioning, and support features |

How is Shoe Fabric Used in Footwear Manufacturing?

In the footwear manufacturing sector, shoe fabric is primarily used for creating uppers for athletic and casual shoes. The choice of fabric impacts not only the shoe’s aesthetic appeal but also its performance attributes, such as breathability and flexibility. For international buyers, especially from diverse markets like Africa and Europe, sourcing durable and lightweight fabrics like nylon and polyester is essential. These fabrics can enhance product longevity while meeting consumer demands for comfort and style.

What Role Does Shoe Fabric Play in Safety and Workwear?

In the safety and workwear industry, shoe fabric is integral to developing protective footwear components. Fabrics must meet stringent safety standards, offering features such as flame resistance and waterproofing. Buyers in regions with rigorous occupational health regulations, such as Germany, need to ensure that their sourced fabrics comply with local standards while providing comfort for long wear. This not only ensures safety compliance but also contributes to employee satisfaction and productivity.

How is Shoe Fabric Utilized in Fashion and Retail?

The fashion and retail sector leverages shoe fabric to create innovative and stylish footwear designs. Utilizing a variety of fabrics allows brands to differentiate their offerings and cater to changing consumer trends. For B2B buyers, particularly in South America and Europe, understanding current fashion trends and fabric characteristics, such as color and texture, is crucial for staying competitive. Sourcing unique and high-quality fabrics can enhance brand identity and attract a discerning customer base.

In What Ways is Shoe Fabric Important for Sports and Outdoor Gear?

Shoe fabric plays a vital role in the production of specialized footwear for sports activities, where performance and safety are paramount. Fabrics that are moisture-wicking and provide adequate grip can significantly enhance athletic performance and reduce injury risks. Buyers from regions with active lifestyles, such as the Middle East, should focus on sourcing fabrics that balance durability with lightweight characteristics to meet the demands of various sports.

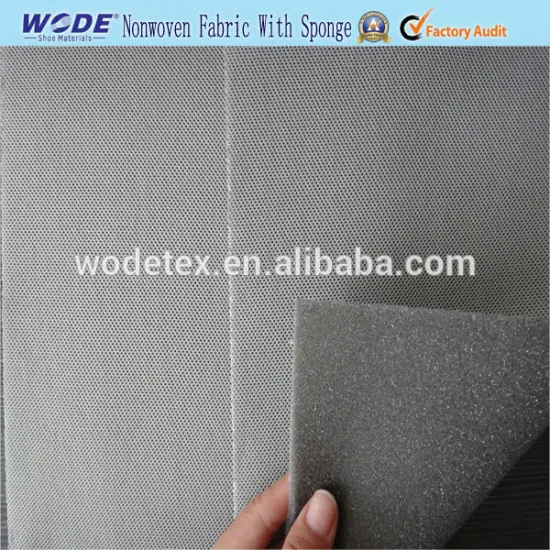

Illustrative image related to shoe fabric

How is Shoe Fabric Applied in Medical and Orthopedic Footwear?

In the medical and orthopedic sector, shoe fabric is used to create custom shoe inserts and specialized footwear that enhance patient mobility and comfort. Key considerations for buyers include the biocompatibility of materials and their cushioning properties. In regions with a high demand for healthcare solutions, such as Africa, sourcing fabrics that provide adequate support while being gentle on the skin can significantly improve patient outcomes and satisfaction.

3 Common User Pain Points for ‘shoe fabric’ & Their Solutions

Scenario 1: Navigating Import Duties on Shoe Fabric

The Problem:

B2B buyers sourcing shoe fabric for manufacturing face significant challenges related to import duties. For example, a company in South America importing textiles for footwear may not realize that materials comprising over 51% textile surface area incur a 20% duty, in addition to other fees. This can drastically increase the cost of goods sold, ultimately affecting pricing strategies and profit margins. Misunderstanding these regulations can lead to unexpected expenses and a bottleneck in production schedules.

The Solution:

To overcome this challenge, buyers should conduct thorough research into the import regulations of their target markets before finalizing fabric orders. Engaging a customs consultant or utilizing trade compliance software can provide insights into duty classifications and help navigate complex tariffs. Additionally, consider sourcing materials that allow for creative design solutions, such as incorporating molded textiles into shoe soles. This can reduce the taxable surface area and lower import duties. Establishing strong relationships with suppliers who understand local regulations can also provide leverage in negotiations and ensure compliance with import laws.

Scenario 2: Ensuring Fabric Durability for Varied Climates

The Problem:

When sourcing shoe fabric, businesses in regions with extreme climates—such as the Middle East’s heat or Africa’s humidity—often struggle to find materials that withstand environmental stressors. A buyer may find that fabrics like cotton absorb moisture and degrade in humid conditions, while synthetics may not breathe well in hot temperatures. This mismatch can lead to high return rates, dissatisfied customers, and a tarnished brand reputation.

The Solution:

To address durability concerns, buyers should prioritize sourcing fabrics specifically engineered for climate resilience. Look for textiles that incorporate moisture-wicking technology or UV resistance, such as treated polyester or specialized blends that combine natural fibers with synthetic materials. Working closely with suppliers to obtain samples and conducting field tests in the intended environment can help assess performance before bulk purchasing. Collaborating with R&D teams to develop custom fabric blends can also lead to innovative solutions that cater to specific climatic challenges, ensuring longevity and customer satisfaction.

Illustrative image related to shoe fabric

Scenario 3: Balancing Cost and Quality in Shoe Fabric Selection

The Problem:

In a competitive market, B2B buyers often face pressure to minimize costs while maintaining quality in their shoe fabric selection. For instance, a European manufacturer may be tempted to cut corners by opting for lower-cost materials, which can compromise the overall quality and performance of the final product. This dilemma often results in sourcing decisions that lead to customer dissatisfaction and increased returns, ultimately harming the business’s bottom line.

The Solution:

To achieve an optimal balance between cost and quality, buyers should adopt a holistic sourcing strategy that emphasizes value over price alone. Conducting a total cost of ownership analysis can reveal the long-term benefits of investing in higher-quality fabrics, such as reduced return rates and increased customer loyalty. Consider establishing partnerships with fabric suppliers who offer transparency about their production processes, certifications, and performance metrics. This can facilitate informed decision-making. Additionally, exploring alternative sourcing options, such as local manufacturers or sustainable materials, can yield competitive pricing without sacrificing quality, aligning with market trends that favor eco-conscious choices.

Strategic Material Selection Guide for shoe fabric

What Are the Key Properties of Common Shoe Fabrics?

When selecting materials for shoe fabric, it is essential to consider their properties in relation to performance, durability, and end-use suitability. Here, we analyze four common materials: polyester, nylon, cotton, and leather, focusing on their characteristics, advantages, disadvantages, and implications for international B2B buyers.

How Does Polyester Perform as a Shoe Fabric?

Polyester is a synthetic fiber known for its strength and durability. It has excellent resistance to stretching and shrinking, making it ideal for various shoe applications. Polyester can withstand high temperatures and is resistant to mildew and abrasion, which enhances its longevity.

Pros: Polyester is lightweight and cost-effective, making it a popular choice for mass-produced footwear. It also offers good color retention and can be treated for water resistance.

Illustrative image related to shoe fabric

Cons: However, polyester is less breathable compared to natural fibers, which may affect comfort in warmer climates. Additionally, it can be prone to pilling over time.

Impact on Application: Polyester is suitable for casual and athletic shoes, especially in humid environments. Buyers should ensure compliance with international standards such as ASTM for safety and performance.

What Advantages Does Nylon Offer for Shoe Fabric?

Nylon is another synthetic material favored for its exceptional strength and elasticity. It exhibits high resistance to wear and tear, making it ideal for high-performance footwear.

Pros: Nylon’s lightweight nature and ability to wick moisture make it suitable for sports shoes. It also resists UV light, ensuring longevity in outdoor applications.

Illustrative image related to shoe fabric

Cons: The primary drawback of nylon is its susceptibility to heat, which can lead to melting if exposed to high temperatures. Additionally, it can be more expensive than polyester.

Impact on Application: Nylon is often used in performance footwear, particularly in regions with high humidity. International buyers should be aware of import regulations and standards specific to their markets.

Why Is Cotton a Preferred Choice for Certain Shoe Fabrics?

Cotton is a natural fiber known for its breathability and comfort. It is particularly valuable in vulcanized shoe construction, where its properties prevent melting during the manufacturing process.

Pros: Cotton’s natural composition allows for excellent moisture absorption and ventilation, making it suitable for casual and summer footwear. It can also be treated for various finishes to enhance its appearance.

Cons: Cotton is less durable than synthetic fibers and can deteriorate faster when exposed to moisture. It may also require more complex manufacturing processes to achieve desired durability.

Impact on Application: Cotton is commonly used in casual and eco-friendly footwear. Buyers should consider regional preferences for natural materials, particularly in markets that value sustainability.

How Does Leather Compare as a Shoe Fabric Option?

Leather is a traditional material renowned for its durability and aesthetic appeal. It offers excellent resistance to wear and provides a classic look that many consumers prefer.

Illustrative image related to shoe fabric

Pros: Leather is highly durable and can be treated for water resistance, making it suitable for various weather conditions. Its natural breathability also contributes to comfort.

Cons: The primary disadvantages are its higher cost and the complexity of the manufacturing process. Leather requires careful sourcing and treatment to ensure quality.

Impact on Application: Leather is often used in high-end and formal footwear. International buyers must consider compliance with animal welfare standards and regulations regarding leather sourcing.

Summary Table of Shoe Fabric Materials

| Material | Typical Use Case for shoe fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Athletic and casual shoes | Lightweight and cost-effective | Less breathable than natural fibers | Low |

| Nylon | Performance footwear | High strength and moisture-wicking | Susceptible to heat | Med |

| Cotton | Casual and eco-friendly shoes | Breathable and comfortable | Less durable when wet | Low |

| Leather | High-end and formal footwear | Durable and aesthetically appealing | Higher cost and complex manufacturing | High |

This guide provides essential insights into material selection for shoe fabric, helping international B2B buyers make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for shoe fabric

Understanding the manufacturing processes and quality assurance practices for shoe fabric is crucial for B2B buyers seeking reliable suppliers. This section outlines the main stages of production, key techniques employed, and the international quality standards that ensure the integrity of the final product.

What Are the Main Stages of Manufacturing Shoe Fabric?

Material Preparation: Sourcing and Initial Treatments

The first step in manufacturing shoe fabric involves sourcing raw materials, which typically include various fibers such as cotton, polyester, nylon, and lycra. Each fiber type offers unique properties that affect the shoe’s performance and aesthetic. For instance, polyester is known for its durability, while cotton provides breathability.

Once the materials are sourced, they undergo initial treatments. This may include dyeing, which enhances the color and visual appeal of the fabric, and sizing, where a liquid resin is applied to give the fabric structure and strength. These treatments are essential to ensure the fabric meets the specific requirements of footwear applications.

Illustrative image related to shoe fabric

Forming: Weaving and Knitting Techniques

After preparation, the next stage is forming the fabric through various techniques such as weaving and knitting. Weaving involves interlacing threads at right angles, resulting in a stable structure. Common weave patterns include plain, twill, and satin, each offering different textures and appearances.

Knitting, on the other hand, creates fabrics by interlocking loops of yarn, allowing for greater elasticity. Techniques like 3D mesh knitting are increasingly popular for athletic footwear, providing breathability and comfort. Understanding these techniques helps buyers select the right fabric based on the intended use of the shoes.

Assembly: Integrating Components

Assembly is a critical stage where various fabric components are joined together to create the shoe. This process may involve lamination, where a thin layer of foam is added to the fabric for added durability and comfort. Proper handling during assembly is essential to avoid damage to the fabric, which can compromise quality.

Quality checks should be integrated at this stage, including assessments of the bonding strength between layers, alignment of patterns, and adherence to design specifications. Ensuring that these factors are correctly managed is vital for maintaining the integrity of the final product.

Finishing: Final Treatments and Quality Control

The finishing stage involves applying surface treatments to enhance the fabric’s properties. Common treatments include water resistance and abrasion resistance, which are crucial for increasing the longevity of the shoes.

At this stage, the fabric is also inspected for defects, such as inconsistencies in color or texture. This final quality control step ensures that only the best materials move forward in the production process.

Illustrative image related to shoe fabric

How Is Quality Assurance Implemented in Shoe Fabric Manufacturing?

What Are the Relevant International Standards for Quality Assurance?

Quality assurance in shoe fabric manufacturing is governed by various international standards, including ISO 9001, which outlines requirements for a quality management system. Adherence to these standards helps manufacturers ensure consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, particularly for specialized footwear that requires additional safety measures. Buyers should inquire about these certifications when evaluating suppliers.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. It helps prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the quality of the fabric and assembly processes. This includes checking for defects and ensuring that production methods align with quality standards.

-

Final Quality Control (FQC): The final inspection occurs before products are shipped. This step verifies that all shoes meet the required specifications, including aesthetic and functional attributes.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers employ various testing methods to assess the quality of shoe fabrics. Common tests include:

-

Tensile Strength Testing: Measures the fabric’s ability to withstand pulling forces.

-

Abrasion Resistance Testing: Evaluates how well the fabric can withstand wear and tear over time.

-

Water Resistance Testing: Assesses the fabric’s ability to repel water, crucial for outdoor and athletic footwear.

-

Colorfastness Testing: Ensures that colors remain stable when exposed to washing, light, and other environmental factors.

These tests help ensure that the fabric meets the performance criteria necessary for its intended use.

Illustrative image related to shoe fabric

How Can B2B Buyers Verify Supplier Quality Control?

What Are Effective Methods for Auditing Supplier Quality?

B2B buyers should conduct thorough audits of potential suppliers to verify their quality control processes. This may include:

-

On-Site Audits: Visiting the manufacturing facility allows buyers to observe production processes and quality control measures firsthand.

-

Reviewing Quality Reports: Suppliers should provide documentation of their quality control practices, including inspection reports and test results.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s quality control measures and compliance with international standards.

What Nuances Should International Buyers Consider?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality assurance. These may include:

-

Understanding Local Regulations: Each region may have unique import regulations and quality standards that must be adhered to.

-

Cultural Differences in Business Practices: Building relationships and trust with suppliers can vary significantly across cultures, impacting negotiations and quality expectations.

-

Logistical Challenges: International shipping can introduce risks related to product integrity. Buyers should ensure that suppliers have robust logistics strategies to mitigate these risks.

By understanding the manufacturing processes and quality assurance measures in shoe fabric production, B2B buyers can make informed decisions and select reliable suppliers that meet their quality standards. This knowledge not only enhances the procurement process but also strengthens partnerships in the global footwear industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoe fabric’

In this guide, we aim to equip B2B buyers with a comprehensive checklist for sourcing shoe fabric. Understanding the nuances of fabric selection is crucial for creating high-quality footwear that meets market demands. This step-by-step approach will help you navigate the complexities of fabric procurement, ensuring that you make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is essential before initiating the sourcing process. This includes determining the types of fabrics required, such as nylon, polyester, or cotton, and their specific attributes like water resistance or breathability. Be precise about the fabric weight (measured in denier) and any specific weave or knit patterns that align with your design needs.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in shoe fabrics. Look for manufacturers with a proven track record in the industry, as well as those that can cater to your specific regional requirements, particularly if you are sourcing from countries like Vietnam, Germany, or those in Africa and South America. Utilize online platforms, trade shows, and industry networks to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications

Before engaging further, verify that your potential suppliers hold relevant certifications and adhere to industry standards. Certifications such as ISO 9001 for quality management and Oeko-Tex for safety in textiles ensure that the fabric meets both quality and safety benchmarks. This step protects your brand and ensures compliance with international trade regulations.

Step 4: Request Samples and Test Fabrics

Request fabric samples from shortlisted suppliers to assess their quality and suitability. Testing these samples for attributes such as colorfastness, durability, and stretchability is crucial. Ensure that the samples reflect the actual production quality, as variations can occur between samples and bulk orders.

Step 5: Understand Pricing Structures and Import Duties

Engage in discussions regarding pricing structures, including minimum order quantities and payment terms. Additionally, familiarize yourself with import duties related to textile products in your target markets. For example, shoes with over 51% textile surface area may incur a 20% duty, which can significantly impact your cost structure.

Illustrative image related to shoe fabric

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate terms and conditions that protect your interests. This includes lead times, quality assurance protocols, and return policies for defective fabrics. Clear agreements will help mitigate risks and ensure smoother operations throughout the procurement process.

Step 7: Establish a Quality Control Process

Implement a quality control process to oversee fabric production and shipment. Regular inspections during manufacturing and pre-shipment checks can prevent quality issues from arising in the final product. Establishing a reliable quality assurance system will ensure that the fabrics meet your specifications and maintain consistency across your footwear line.

By following this practical sourcing guide, B2B buyers can effectively navigate the complexities of shoe fabric procurement, ensuring they select the right materials that align with their business goals and market demands.

Illustrative image related to shoe fabric

Comprehensive Cost and Pricing Analysis for shoe fabric Sourcing

What Are the Key Cost Components in Shoe Fabric Sourcing?

When sourcing shoe fabric, understanding the cost structure is vital for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The choice of fabric significantly impacts costs. Common materials such as polyester and nylon are typically more affordable than specialized options like high-tech mesh or treated cotton. Prices can vary based on the quality and specifications of the fibers used.

-

Labor: Labor costs can fluctuate depending on the region of production. For instance, countries with lower labor costs, such as Vietnam, may offer more competitive pricing compared to European manufacturers. However, it’s essential to consider the skill level of the workforce, as higher expertise can yield better quality, potentially reducing waste and rework.

-

Manufacturing Overhead: This includes costs associated with running production facilities, such as utilities and maintenance. Efficient factories may have lower overhead, which can translate to better pricing for buyers.

-

Tooling: Initial tooling costs can be significant, especially for custom designs or specifications. Buyers should factor in these costs when assessing the overall expense of sourcing specific fabrics.

-

Quality Control: Ensuring that fabrics meet quality standards can incur additional costs. Implementing rigorous QC processes can prevent costly returns and enhance brand reputation.

-

Logistics: Shipping and handling costs vary widely based on the supplier’s location and the destination. Understanding Incoterms (International Commercial Terms) is crucial to negotiating logistics costs effectively.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Shoe Fabric Sourcing?

Several factors influence the pricing of shoe fabrics, particularly for international B2B buyers.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Larger orders often lead to bulk discounts, making it essential for buyers to negotiate favorable terms.

-

Specifications and Customization: Custom fabrics or specific specifications can increase costs. Buyers should weigh the necessity of customization against potential budget constraints.

-

Quality and Certifications: Fabrics that meet international quality standards or possess certifications (like OEKO-TEX) may command higher prices but can also reduce liability and enhance consumer trust.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge a premium, but this can lead to better service and quality assurance.

What Buyer Tips Can Enhance Cost-Efficiency in Shoe Fabric Sourcing?

For B2B buyers navigating the complexities of international sourcing, several strategies can enhance cost-efficiency.

-

Negotiation: Effective negotiation can yield significant savings. Building a relationship with suppliers can lead to better pricing and terms.

-

Total Cost of Ownership: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, duties, and potential returns. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of the varying import duties and tariffs that may apply based on the fabric’s composition and the country of origin. For instance, shoes with a textile surface area exceeding 51% may incur a 20% duty, impacting the overall cost.

Conclusion

Understanding the cost components and price influencers in shoe fabric sourcing is crucial for international B2B buyers. By employing strategic negotiation, considering the Total Cost of Ownership, and remaining aware of regional pricing nuances, buyers can enhance their sourcing efficiency and ultimately improve their bottom line. While indicative prices can guide initial discussions, always verify current market rates and supplier capabilities for the most accurate budgeting.

Alternatives Analysis: Comparing shoe fabric With Other Solutions

The selection of materials for shoe production is critical in determining the performance, durability, and overall appeal of the final product. While shoe fabric is widely used due to its versatility and functionality, several alternative solutions exist that may better suit specific manufacturing needs. This section explores these alternatives, providing B2B buyers with a comprehensive analysis to facilitate informed decision-making.

| Comparison Aspect | Shoe Fabric | Synthetic Leather | Rubber Material |

|---|---|---|---|

| Performance | Lightweight and breathable; good flexibility. | Durable and water-resistant; mimics leather aesthetics. | Excellent grip and durability; ideal for rugged use. |

| Cost | Generally moderate, varies with type and treatment. | Higher initial cost but offers longevity. | Cost-effective, especially for bulk purchases. |

| Ease of Implementation | Easy to work with; requires specific techniques for bonding. | Requires specialized machinery for cutting and sewing. | Simple to mold and shape; straightforward manufacturing process. |

| Maintenance | Requires regular cleaning; can absorb moisture. | Easy to clean; resistant to stains. | Minimal maintenance; very durable against wear. |

| Best Use Case | Casual and athletic shoes, fashion footwear. | Fashion-forward designs, high-end casual shoes. | Work boots, outdoor shoes, heavy-duty applications. |

What Are the Advantages and Disadvantages of Synthetic Leather?

Synthetic leather, also known as faux leather, is a popular alternative that closely resembles genuine leather but is made from polymers. Its primary advantage lies in its durability and water resistance, making it an excellent choice for various shoe designs. Additionally, synthetic leather is often easier to clean and maintain compared to fabric. However, the initial cost can be higher, and it may lack the breathability of natural materials, potentially leading to discomfort in warmer climates.

How Does Rubber Material Compare in Shoe Manufacturing?

Rubber is another viable alternative, particularly favored for its exceptional grip and durability. It is widely used in the production of outsoles, providing traction and support for various footwear types. Rubber materials are generally cost-effective, especially for bulk orders, and they require minimal maintenance. However, rubber can be heavier than fabric, which may affect the overall weight of the shoe. Furthermore, the aesthetic options are somewhat limited compared to the diverse patterns and colors available in fabrics.

How Can B2B Buyers Choose the Right Material for Their Needs?

When deciding between shoe fabric and its alternatives, B2B buyers should evaluate their specific requirements, including performance characteristics, budget constraints, and the intended use case of the footwear. For instance, if creating high-end fashion shoes that prioritize aesthetics, synthetic leather may be more suitable. Conversely, if the focus is on functionality and ruggedness for outdoor or industrial applications, rubber would be the better choice. Ultimately, understanding the trade-offs associated with each material will empower buyers to make informed decisions that align with their production goals and market demands.

Essential Technical Properties and Trade Terminology for shoe fabric

What Are the Key Technical Properties of Shoe Fabric That Buyers Should Know?

Understanding the essential technical properties of shoe fabric is crucial for international B2B buyers, particularly when sourcing materials that meet specific performance and design standards. Here are some critical specifications to consider:

1. Denier (D)

Denier is a unit of measurement that indicates the thickness of the thread used in the fabric. The denier value directly correlates with the fabric’s weight and durability. For instance, lightweight fabrics often range from 110D, while more robust materials used in footwear can be between 420D to 600D. Knowing the denier is vital for buyers as it affects both the performance and the feel of the shoe, influencing factors such as breathability and longevity.

Illustrative image related to shoe fabric

2. Fiber Composition

The choice of fiber in shoe fabric significantly impacts its characteristics. Common fibers include polyester, nylon, cotton, and Lycra. Each fiber has unique properties, such as water resistance, stretchability, and UV resistance. For example, polyester and nylon are favored for their durability, while cotton is essential for vulcanized shoes due to its heat resistance. Understanding fiber composition helps buyers align their product offerings with market demands for quality and performance.

3. Weave and Knit Patterns

The construction method of the fabric—whether woven or knitted—determines its elasticity, strength, and aesthetic appeal. Woven fabrics consist of interlaced threads, while knitted fabrics are formed by interlocking loops. Different patterns like twill, satin, or jersey provide varying degrees of flexibility and texture. Buyers should consider these patterns when sourcing materials, as they influence the shoe’s overall design and functionality.

4. Surface Treatments

Surface treatments enhance the fabric’s performance characteristics. Treatments such as Durable Water Resistant (DWR) coatings improve water repellency, while brushing techniques can add softness and comfort. Buyers must be aware of these treatments as they can significantly affect the end-user experience and the fabric’s suitability for specific applications, such as sports or casual footwear.

5. Backing Materials

The backing material plays a crucial role in the fabric’s durability and appearance. Common types include polyurethane (PU) and polyvinyl chloride (PVC). PU offers a lightweight and less waterproof option, while PVC provides a sturdier and more solid feel. Buyers should choose backing materials based on the desired durability and water resistance of the final product.

What Are Common Industry Terms in Shoe Fabric Sourcing?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B footwear fabric market. Here are several key terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the footwear industry, an OEM may produce shoe fabric that is then branded and sold by a different company. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better pricing structures.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the shoe fabric market, MOQs can vary significantly depending on the manufacturer and the type of fabric. Knowing the MOQ is crucial for buyers to manage inventory levels effectively and to ensure that they can meet production demands without overcommitting resources.

Illustrative image related to shoe fabric

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the context of shoe fabric, an RFQ helps buyers gather competitive pricing and terms from multiple suppliers, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and freight. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who is responsible for costs and risks during transportation. Understanding Incoterms is vital for buyers to navigate logistics and avoid unexpected costs in international trade.

5. DWR (Durable Water Repellent)

DWR is a treatment applied to fabrics to make them resistant to water. This property is particularly important in footwear designed for outdoor or wet conditions. Buyers should consider DWR-treated fabrics for products aimed at consumers seeking performance in adverse weather conditions.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing shoe fabric, ensuring that their products meet quality standards and market expectations.

Navigating Market Dynamics and Sourcing Trends in the shoe fabric Sector

What Are the Current Market Dynamics and Key Trends in the Shoe Fabric Sector?

The global shoe fabric market is experiencing significant transformation driven by a combination of technological advancements and shifting consumer preferences. Key trends include the rise of synthetic fabrics, particularly nylon and polyester, due to their lightweight and durable nature. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking these materials as they meet both performance and cost-efficiency needs. Additionally, the emergence of high-tech fabrics, such as 3D mesh and moisture-wicking textiles, is gaining traction, particularly for athletic and lifestyle footwear, as consumers prioritize comfort and functionality.

Another dynamic is the growing integration of digital technologies in sourcing processes. Platforms that utilize AI and machine learning for predictive analytics are enabling buyers to optimize their procurement strategies, ensuring they stay ahead of market fluctuations and demand shifts. Furthermore, blockchain technology is being explored for supply chain transparency, allowing buyers to verify the authenticity and origin of materials, which is crucial in today’s ethical consumerism landscape.

How Is Sustainability Influencing Sourcing Trends for Shoe Fabrics?

Sustainability has become a critical factor for B2B buyers in the shoe fabric sector. The environmental impact of textile production is significant, leading to increased scrutiny of supply chains. Buyers are now prioritizing ethical sourcing practices that minimize ecological footprints. This includes selecting materials that are certified as organic or recycled, such as recycled polyester, which reduces reliance on virgin resources and lowers carbon emissions.

Moreover, the demand for ‘green’ certifications is rising. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® are becoming essential for buyers looking to align their sourcing practices with sustainable values. This trend is not only about compliance but also about meeting consumer expectations for transparency and responsibility. Buyers who invest in sustainable materials often see a boost in brand loyalty and market differentiation, making it a strategic advantage in a competitive landscape.

What Is the Evolution of Shoe Fabric Sourcing and Its Relevance Today?

Historically, shoe fabric sourcing has evolved from a heavy reliance on natural fibers to a more complex blend of synthetic and high-performance materials. In the early 20th century, cotton and leather dominated the market, but as technological innovations emerged, the introduction of synthetic fibers transformed design possibilities and production efficiencies.

Today, this evolution continues as manufacturers and buyers explore advanced materials that offer not only durability but also unique aesthetic qualities. This shift is particularly relevant for B2B buyers who need to adapt to rapidly changing consumer preferences and market demands. Understanding this history provides valuable context for making informed decisions in the current landscape, where innovation and sustainability are paramount.

In summary, the shoe fabric sector is marked by rapid changes driven by technological advancements and growing environmental concerns. B2B buyers must navigate these dynamics effectively, prioritizing sustainability while leveraging new technologies to optimize their sourcing strategies.

Illustrative image related to shoe fabric

Frequently Asked Questions (FAQs) for B2B Buyers of shoe fabric

-

How do I choose the right fabric for my shoe designs?

Selecting the right fabric for shoe designs involves considering several factors. Focus on the intended use of the shoe—whether it’s for sports, fashion, or work—since different applications require different properties. Evaluate fabric types based on durability, weight, and comfort. For instance, polyester and nylon are excellent for their strength and water resistance, while cotton is ideal for vulcanized shoes. Additionally, consider thread size (denier), weave pattern, and any required surface treatments to ensure the fabric meets your design specifications. -

What are the most common fabrics used in shoe manufacturing?

The most common fabrics used in shoe manufacturing include nylon, polyester, cotton canvas, and lycra. Nylon and polyester are favored for their durability and lightweight properties, making them suitable for athletic and outdoor footwear. Cotton canvas is essential for vulcanized shoes, as it withstands high temperatures without melting. Lycra is often used for its stretchability, particularly in linings and bindings. Understanding these materials can help you make informed decisions based on your product’s target market. -

What should I know about minimum order quantities (MOQ) for shoe fabrics?

Minimum order quantities (MOQ) for shoe fabrics can vary significantly based on the supplier and the type of fabric. Typically, MOQs range from 500 to 1,000 meters for standard fabrics, but specialty or custom fabrics may have higher MOQs. It’s essential to discuss your specific needs with suppliers to negotiate MOQs that align with your production capabilities. Smaller businesses or startups may also look for suppliers that offer lower MOQs to facilitate initial product launches without significant investment. -

How can I effectively vet suppliers for shoe fabric?

When vetting suppliers for shoe fabric, consider several critical factors. Start by researching the supplier’s reputation in the industry, checking for reviews and testimonials from other clients. Evaluate their production capabilities, including their ability to meet quality standards and delivery timelines. Request samples to assess the fabric quality firsthand, and inquire about certifications such as ISO or OEKO-TEX to ensure compliance with safety and environmental standards. Establishing a strong communication channel is also vital for a successful partnership. -

What are the typical payment terms when sourcing shoe fabric internationally?

Payment terms for international sourcing of shoe fabric can vary, but common practices include upfront deposits of 30-50% with the balance due upon shipment or delivery. Letters of credit (LC) are also frequently used to mitigate risk for both buyers and suppliers. It’s essential to clarify payment methods, currency, and any potential fees during negotiations to avoid misunderstandings. Always ensure that the payment terms align with your cash flow and financial capabilities. -

How do I ensure quality assurance in my shoe fabric orders?

To ensure quality assurance in your shoe fabric orders, implement a robust quality control process. Start by establishing clear specifications for the fabrics, including weight, color, and durability. Request pre-production samples to evaluate quality before full-scale production begins. Conduct regular inspections during manufacturing, and consider hiring third-party quality assurance services for unbiased assessments. Establishing a solid relationship with your supplier can also facilitate better communication regarding quality expectations and issue resolution. -

What logistics considerations should I keep in mind when importing shoe fabrics?

When importing shoe fabrics, several logistics considerations are crucial. Assess shipping options and costs, including air vs. sea freight, based on your budget and delivery timelines. Be aware of import duties and taxes that may apply in your country, as these can significantly impact overall costs. Ensure that your supplier provides accurate documentation for customs clearance, including invoices and packing lists. Finally, consider partnering with a freight forwarder to streamline the logistics process and mitigate potential delays. -

What are the common import duties for shoe fabrics and how can I minimize them?

Import duties for shoe fabrics can vary by country, often ranging from 5% to 20% based on fabric type and country of origin. To minimize these costs, consider sourcing materials from countries with favorable trade agreements or lower duty rates. Additionally, structuring your product to comply with local regulations can help; for example, ensuring that at least 51% of the shoe’s surface area consists of textile material can sometimes lead to different duty assessments. Always consult with a customs broker to understand the specific regulations applicable to your imports.

Top 7 Shoe Fabric Manufacturers & Suppliers List

1. Etsy – Unique Shoe Fabrics

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Unique Shoe Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Shoemakers Academy – Essential Textiles for Shoe Design

Domain: shoemakersacademy.com

Registered: 2022 (3 years)

Introduction: Textiles for Shoe Design: Understanding fabrics is essential for shoe design. Key textiles include nylon, polyester, lycra, and cotton canvas. Important considerations are thread size (measured in denier), fiber composition, weave pattern, backing material, sizing, and surface treatments. Common deniers range from 110D (lightweight) to 1000D (for boots). Fiber types include cotton, wool, nylon, po…

3. Shoe Print Fabric – Various Colors & Lengths

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Shoe Print Fabric available in various colors including Blue, Green, Black, Multicolor, White, Pink, Red, Beige, Gray, Brown, Purple, Yellow. Available lengths/amounts: By the Yard, 1 – 2 yds, 3 – 5 yds, 6 – 12 yds, Fat Quarters, Bundles, Jelly Rolls, Strips, Less than 1 yd, Squares, Panels, Bolts, Tubes, Lots. Width: 39-inch by Length 1 Yard.

4. Wendy Custom – Classic Louis Vuitton Leather Fabrics

Domain: wendycustom.com

Registered: 2022 (3 years)

Introduction: [{‘name’: ‘Classic Louis Vuitton LV Designer Leather Sheet fabric for bag leather, sofa leather’, ‘price’: ‘From $25.00 USD’}, {‘name’: ‘Black embossed LV craft Faux leather fabric by yard’, ‘price’: ‘From $10.00 USD’}, {‘name’: ‘Classic black grey Louis Vuitton LV Designer Leather custom leather fabric for bag leather, sofa leather’, ‘price’: ‘From $5.00 USD’}, {‘name’: ‘Luxury Black Velvet LV fo…

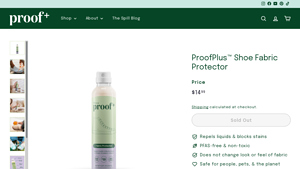

5. ProofPlus – Shoe Fabric Protector

Domain: proofplus.co

Registered: 2023 (2 years)

Introduction: {“product_name”: “ProofPlus™ Shoe Fabric Protector”, “price”: “$14.99”, “availability”: “Sold Out”, “features”: [“Repels liquids & blocks stains”, “PFAS-free & non-toxic”, “Does not change look or feel of fabric”, “Safe for people, pets, & the planet”], “application_instructions”: [“Clean surface”, “Spray 6′-8″ from surface”, “Wait 30-60 minutes”, “Reapply protector”, “Air dry for 24-48 hours”], “…

6. Spoonflower – Custom Fabric & Home Decor

Domain: spoonflower.com

Registered: 2005 (20 years)

Introduction: Shoe-pattern designs available in fabric by the yard, fabric by the meter, wallpaper, and home decor items such as curtains, bedding, pillows, and dining products. Supports Spoonflower’s community of artists. Custom designs can be uploaded for printing.

7. Monofabrics – Expert Shoe Fabrics

Domain: monofabrics.com

Registered: 2018 (7 years)

Introduction: Expert Fabrics for Shoes by Wei-Syun, a trusted shoe fabric manufacturer. Key features include:

– Fabrics designed for shoe uppers, suitable for sneakers and hiking shoes.

– Focus on lightness, thinness, breathability, wear resistance, tension, and extension.

– Continuous innovation in shoe materials, utilizing various types of yarns such as TPU, MONO Monofilament, and CODURA for enhanced stren…

Strategic Sourcing Conclusion and Outlook for shoe fabric

What Are the Key Takeaways for Strategic Sourcing in Shoe Fabric?

In conclusion, strategic sourcing in shoe fabric is essential for international B2B buyers seeking to optimize their supply chains and enhance product quality. Understanding the intricate properties of various textiles, from lightweight nylon to robust cotton canvas, allows businesses to make informed decisions that align with their design and production needs. Consideration of factors such as thread size, fiber composition, and surface treatments can significantly impact the durability and aesthetic appeal of footwear.

Moreover, the importance of sourcing high-quality materials cannot be overstated. Reliable suppliers not only ensure compliance with import regulations but also offer innovative solutions that can differentiate products in a competitive market. As the global footwear industry evolves, embracing sustainable and technologically advanced materials will be crucial for maintaining market relevance.

How Can International B2B Buyers Prepare for Future Trends in Shoe Fabric?

Looking ahead, international buyers, particularly from Africa, South America, the Middle East, and Europe, should stay attuned to emerging trends in shoe fabric innovation. Engaging with suppliers who prioritize sustainability and advanced textile technologies will position your business for success. As you explore new partnerships, leverage the insights from this guide to enhance your sourcing strategies, and ensure your footwear offerings meet the evolving demands of consumers. Take the proactive step today—invest in quality sourcing to elevate your brand’s potential in the dynamic global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.