Introduction: Navigating the Global Market for leather stamp maker

In today’s competitive landscape, sourcing the right leather stamp maker is crucial for businesses aiming to enhance their branding and product personalization. With diverse applications ranging from custom logos to intricate designs, navigating the global market for leather stamps can pose significant challenges for international B2B buyers. This guide provides a comprehensive overview of essential factors, including various types of leather stamps, their applications across industries, effective supplier vetting processes, and cost considerations.

By delving into the specifics of what makes a quality leather stamp maker, this resource empowers businesses from regions such as Africa, South America, the Middle East, and Europe—like Nigeria and Germany—to make informed purchasing decisions. Whether you are a small artisan shop or a large manufacturing entity, understanding the nuances of leather stamping can lead to improved product quality and customer satisfaction.

The insights shared in this guide are designed to streamline your sourcing process, ensuring you find reliable suppliers that meet your specific needs. From understanding the materials used to evaluating turnaround times and customer service, we equip you with the knowledge necessary to select a leather stamp maker that aligns with your business goals. By the end of this guide, you will be well-prepared to navigate the complexities of the leather stamping market and capitalize on the opportunities it presents.

Table Of Contents

- Top 7 Leather Stamp Maker Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather stamp maker

- Understanding leather stamp maker Types and Variations

- Key Industrial Applications of leather stamp maker

- 3 Common User Pain Points for ‘leather stamp maker’ & Their Solutions

- Strategic Material Selection Guide for leather stamp maker

- In-depth Look: Manufacturing Processes and Quality Assurance for leather stamp maker

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather stamp maker’

- Comprehensive Cost and Pricing Analysis for leather stamp maker Sourcing

- Alternatives Analysis: Comparing leather stamp maker With Other Solutions

- Essential Technical Properties and Trade Terminology for leather stamp maker

- Navigating Market Dynamics and Sourcing Trends in the leather stamp maker Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather stamp maker

- Strategic Sourcing Conclusion and Outlook for leather stamp maker

- Important Disclaimer & Terms of Use

Understanding leather stamp maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Brass Stamps | CNC milled, customizable designs, quick turnaround | Branding, logos, personalized items | Pros: High precision, fast delivery. Cons: Higher initial cost. |

| Leather Cutting Dies | Made from solid steel, custom shapes, used with presses | Mass production, intricate designs | Pros: Durable, efficient for large runs. Cons: Requires press machinery. |

| Letter Sets | Alphabet and symbol sets, compatible with various machines | Custom text stamping | Pros: Versatile, easy to use. Cons: Limited to specific fonts. |

| Heat Branding Stamps | Designed for heat application, durable materials | Leather goods, apparel branding | Pros: Strong, lasting impressions. Cons: Requires heat source for operation. |

| Miniature Stamps | Compact size, ideal for detailed work | Crafting, small-scale branding | Pros: Precision for small designs. Cons: Limited in size and impact. |

What are Custom Brass Stamps and Their B2B Relevance?

Custom brass stamps are CNC milled to create precise and intricate designs, making them ideal for branding and personalizing leather goods. Their quick turnaround time is particularly beneficial for businesses needing rapid production. Buyers should consider the initial investment, as custom brass stamps can be more expensive than standard options, but the durability and quality often justify the cost.

How Do Leather Cutting Dies Enhance Production Efficiency?

Leather cutting dies are crafted from solid steel and are designed for use with mechanical or hydraulic presses. They enable businesses to mass-produce intricate designs with minimal manual labor. This efficiency is crucial for companies scaling production. However, buyers need to ensure they have the appropriate machinery to utilize these dies effectively, as the upfront costs can be significant.

Why are Letter Sets Important for Custom Text Stamping?

Letter sets provide a range of customizable alphabets and symbols compatible with various stamping machines, allowing businesses to create custom text on leather products. Their versatility makes them essential for branding and personalization. While they are easy to use, buyers should be aware that they are often limited to specific font styles, which may not suit all branding needs.

What Advantages Do Heat Branding Stamps Offer?

Heat branding stamps are designed to create lasting impressions on leather through heat application. They are particularly effective for branding leather goods and apparel, providing a strong and durable mark. However, businesses must invest in a reliable heat source, which can add to the overall cost. The longevity of the branding makes them a worthwhile investment for companies focused on quality.

How Can Miniature Stamps Be Utilized in Crafting?

Miniature stamps are compact tools ideal for detailed work, making them perfect for crafting and small-scale branding. They allow for precision in small designs, catering to niche markets or artisanal products. While they excel in detail, buyers should consider that their smaller size may limit the impact of branding, making them best suited for specific applications rather than broad branding efforts.

Key Industrial Applications of leather stamp maker

| Industry/Sector | Specific Application of leather stamp maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Leather Goods Manufacturing | Custom branding stamps for leather products | Enhances brand recognition and product differentiation | Quality of materials, customization options, turnaround time |

| Fashion and Apparel | Personalized logo stamps for clothing | Adds unique branding elements to clothing lines | Design flexibility, compatibility with various fabrics, durability |

| Craft and Hobby | Custom stamps for DIY leather projects | Empowers artisans with tools for creativity and branding | Ease of use, variety of designs, customer support availability |

| E-commerce | Branding and packaging stamps | Professionalizes packaging and enhances customer experience | Shipping options, cost-effectiveness, production speed |

| Automotive and Upholstery | Custom stamps for leather car interiors | Elevates luxury appeal and personalization of vehicles | Precision in design, material compatibility, scalability |

How Can Leather Stamp Makers Enhance Leather Goods Manufacturing?

In the leather goods manufacturing sector, custom branding stamps from leather stamp makers are essential for creating distinct product identities. Manufacturers can utilize these stamps to imprint their logos or unique designs onto leather items, which helps in enhancing brand recognition and product differentiation. For international buyers, particularly in regions like Africa and South America, sourcing high-quality materials and ensuring timely delivery are critical factors. Customization options, such as varying sizes and designs, also play a significant role in meeting diverse market demands.

What Role Do Leather Stamps Play in Fashion and Apparel?

In the fashion and apparel industry, personalized logo stamps are increasingly used to add unique branding elements to clothing lines. These stamps can be applied to leather accents on garments, providing a bespoke touch that appeals to consumers. Buyers from Europe, such as Germany, often seek high-quality, durable stamps that can withstand frequent use. Ensuring compatibility with various fabrics and ease of application are key considerations for brands looking to maintain efficiency in production while elevating their fashion offerings.

How Do Leather Stamp Makers Benefit Craft and Hobby Businesses?

For the craft and hobby sector, custom stamps enable artisans to create unique leather products, empowering them to express creativity while also establishing their brand. These stamps can be used for DIY projects, allowing crafters to personalize items for themselves or their clients. Buyers should consider the ease of use and variety of design options offered by suppliers, as well as the availability of customer support to assist with any technical inquiries. This is particularly important for international buyers who may require additional guidance in the stamping process.

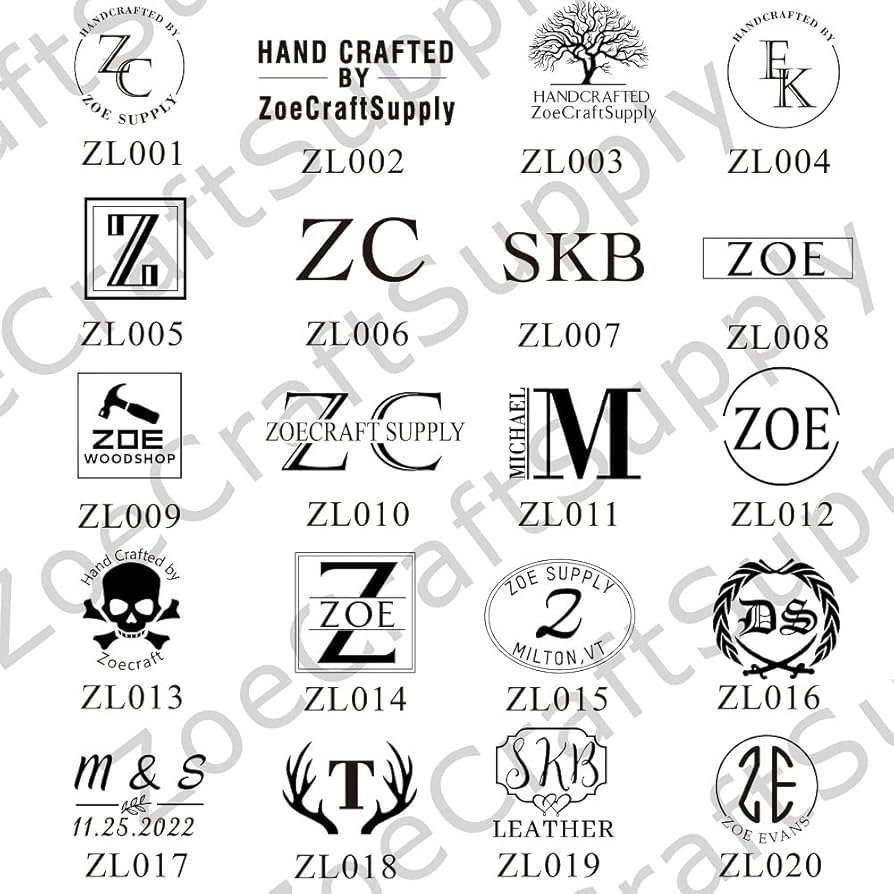

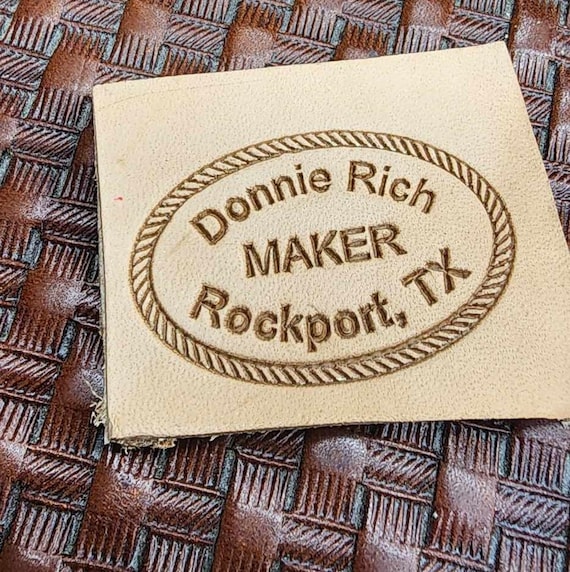

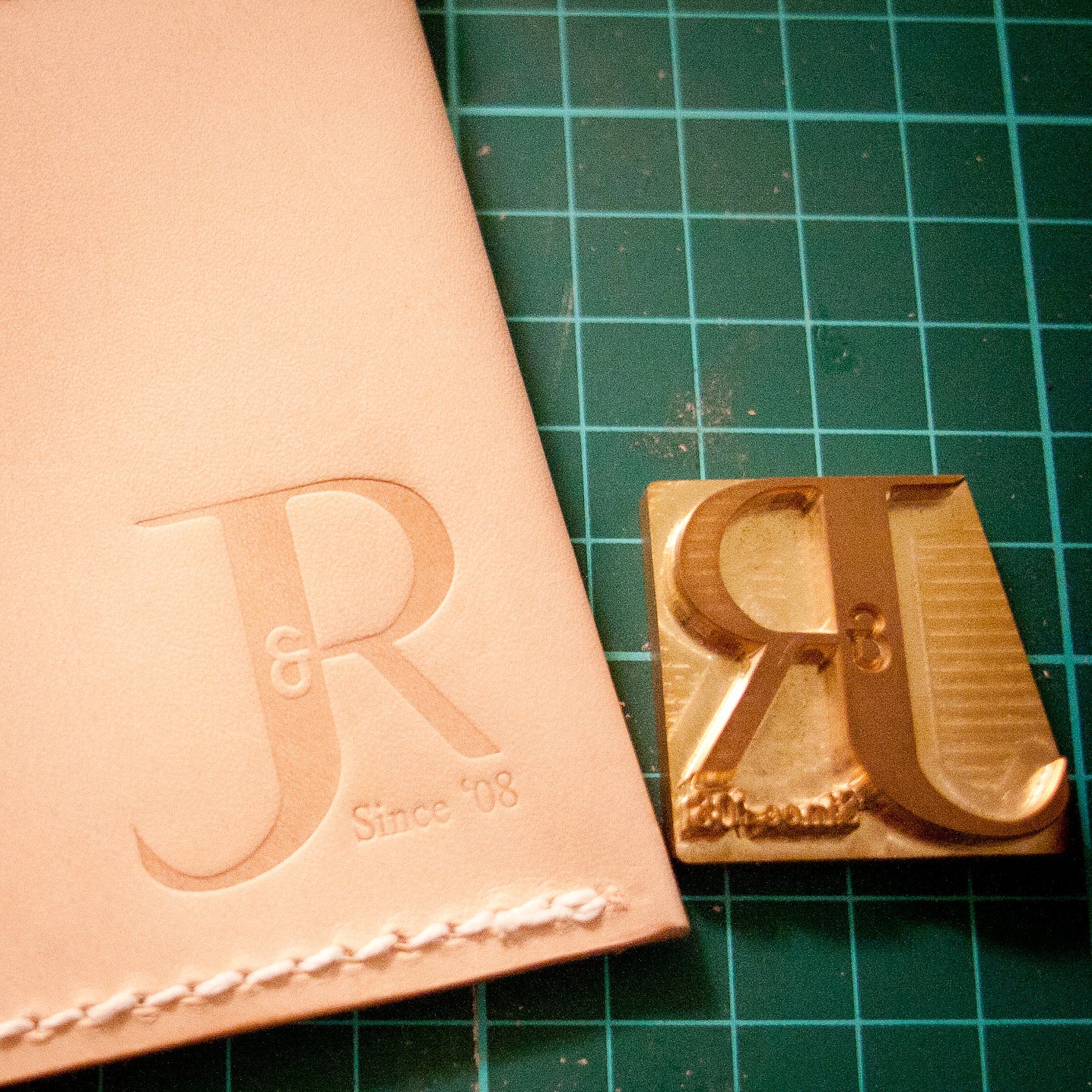

Illustrative image related to leather stamp maker

How Can E-commerce Businesses Leverage Leather Stamps for Branding?

E-commerce businesses can utilize branding and packaging stamps to professionalize their product presentation. Stamping leather packaging or labels can significantly enhance the customer experience, creating a memorable unboxing moment. Key sourcing considerations for these businesses include shipping options and cost-effectiveness, as well as the speed of production to meet consumer demand. International buyers should also evaluate the supplier’s ability to deliver consistent quality across large orders.

What Are the Advantages of Using Leather Stamps in Automotive and Upholstery Industries?

In the automotive and upholstery sectors, custom stamps are used to personalize leather interiors, adding a touch of luxury to vehicles. This application not only elevates the aesthetic appeal but also allows manufacturers to cater to specific customer preferences. Precision in design and material compatibility are crucial for ensuring that stamps work effectively on automotive leather. International buyers should prioritize suppliers who can scale production while maintaining high quality, particularly when dealing with larger automotive contracts.

3 Common User Pain Points for ‘leather stamp maker’ & Their Solutions

Scenario 1: Difficulty in Custom Design Approval Process

The Problem: Many B2B buyers face challenges when trying to create custom designs for leather stamps. The approval process can be frustrating, especially when there are multiple iterations required before reaching a satisfactory design. Buyers often feel overwhelmed by the technical aspects of specifying their needs, leading to delays in production and potential miscommunication with manufacturers. This can be particularly disheartening for businesses that rely on timely delivery to meet customer demands or project deadlines.

The Solution: To streamline the custom design approval process, buyers should take advantage of companies that offer a clear and structured system for submitting design requests. Start by preparing high-resolution artwork and clear specifications regarding size, depth, and font preferences. Utilize platforms that provide a virtual proofing system, allowing you to visualize the stamp before it is produced. This can significantly reduce the back-and-forth communication by enabling you to confirm that the design meets your expectations upfront. Additionally, consider engaging directly with customer service representatives who can guide you through the design process. Their expertise can help clarify any technical details and ensure that your vision is accurately captured.

Scenario 2: Concerns Over Material Quality and Durability

The Problem: B2B buyers often worry about the longevity and performance of the leather stamps they purchase. High-quality materials are crucial for ensuring that stamps produce clear and consistent impressions over time. Buyers may have had past experiences with inferior products that wore down quickly or failed to meet their quality standards, which can damage their reputation and business relationships.

The Solution: To address concerns regarding material quality, conduct thorough research on manufacturers that prioritize craftsmanship and use high-grade materials. Look for suppliers who provide detailed information about the materials used in their stamps, such as solid brass for custom designs and solid steel for cutting dies. When possible, request samples or read customer testimonials to gauge product durability. Additionally, inquire about warranties or guarantees offered by the supplier; reputable companies often stand behind their products and provide assurances that can offer peace of mind. Establishing a relationship with a supplier who values quality can lead to more reliable products and reduce the risk of future issues.

Scenario 3: Navigating the Learning Curve in Leather Stamping

The Problem: Newcomers to leather stamping often encounter a steep learning curve, making it difficult to achieve professional-quality results right away. B2B buyers may be uncertain about the best practices for using leather stamps, the correct techniques for heat branding, or how to properly maintain their equipment. This lack of knowledge can lead to frustration, wasted materials, and subpar finished products that fail to meet customer expectations.

The Solution: To overcome this learning curve, buyers should seek out educational resources provided by their suppliers. Many reputable leather stamp manufacturers offer comprehensive guides, tutorials, and videos that demonstrate effective stamping techniques and maintenance practices. Taking the time to engage with these resources can significantly enhance your skills and confidence. Additionally, consider joining online forums or communities focused on leatherworking where you can exchange tips and experiences with other professionals. This collaborative approach can provide valuable insights and support as you refine your techniques. Finally, don’t hesitate to reach out to customer service for personalized assistance; they can often provide tailored advice based on your specific projects and challenges.

Strategic Material Selection Guide for leather stamp maker

When selecting materials for leather stamps, it is essential to consider the properties and performance of each option to ensure they meet the specific needs of your applications. Here, we analyze four common materials used in leather stamp manufacturing: brass, steel, aluminum, and polymer. Each material has unique characteristics that influence their suitability for different stamping tasks.

What Are the Key Properties of Brass for Leather Stamps?

Brass is a popular choice for leather stamps due to its excellent machinability and durability. It can withstand high temperatures and pressures, making it suitable for heat branding applications. Brass also exhibits good corrosion resistance, which is essential for maintaining the quality of stamps used in humid environments.

Illustrative image related to leather stamp maker

Pros and Cons of Brass:

– Pros: High durability, excellent detail retention, and good thermal conductivity.

– Cons: Higher cost compared to other materials and may tarnish over time if not properly maintained.

Impact on Application:

Brass stamps are ideal for creating intricate designs and logos on leather, as they can hold fine details well. However, they may require regular polishing to maintain their appearance, particularly in regions with high humidity.

How Does Steel Compare in Terms of Performance for Leather Stamps?

Steel, particularly carbon steel, is favored for its strength and durability. It can withstand significant wear and tear, making it suitable for high-volume production runs. Steel stamps can also be produced with varying hardness levels, allowing for customization based on specific application requirements.

Pros and Cons of Steel:

– Pros: Exceptional durability, cost-effective for large-scale production, and can be hardened for longevity.

– Cons: Prone to rust if not properly treated and can be more challenging to machine than brass.

Impact on Application:

Steel stamps are well-suited for heavy-duty applications where longevity is critical. However, their susceptibility to corrosion necessitates protective coatings, especially in regions with high moisture levels.

What Are the Advantages of Using Aluminum for Leather Stamps?

Aluminum is a lightweight and cost-effective material that is easy to machine. It is less durable than brass or steel but can be suitable for low-volume production or prototyping. Aluminum stamps can be anodized for improved corrosion resistance, making them viable for various environments.

Pros and Cons of Aluminum:

– Pros: Lightweight, lower cost, and easy to machine.

– Cons: Lower durability and may not hold fine details as well as brass or steel.

Impact on Application:

Aluminum is ideal for applications requiring quick turnaround times and lower production costs. However, it may not be the best choice for intricate designs or high-volume stamping due to its limited durability.

What Role Do Polymers Play in Leather Stamping Applications?

Polymer materials, such as photopolymer resins, are increasingly used for making stamps due to their flexibility and ease of use. They can be produced quickly through 3D printing or molding, allowing for rapid prototyping and customization.

Illustrative image related to leather stamp maker

Pros and Cons of Polymers:

– Pros: Quick production times, cost-effective for short runs, and customizable.

– Cons: Generally less durable than metal options and may not withstand high temperatures.

Impact on Application:

Polymers are suitable for applications where rapid prototyping is essential, or when working with less intricate designs. However, their limited heat resistance may restrict their use in heat branding applications.

Summary Table of Material Selection for Leather Stamps

| المواد | Typical Use Case for leather stamp maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Custom logos and intricate designs | Excellent detail retention | Higher cost and tarnishing issues | عالية |

| Steel | High-volume production runs | Exceptional durability | Prone to rust without treatment | Medium |

| Aluminum | Low-volume production and prototyping | Lightweight and cost-effective | Lower durability | منخفضة |

| Polymer | Rapid prototyping and simple designs | Quick production times | Less durable and heat-sensitive | منخفضة |

This strategic material selection guide provides valuable insights for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the properties, advantages, and limitations of each material can help in making informed decisions that align with specific production needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for leather stamp maker

What Are the Key Manufacturing Processes for Leather Stamp Makers?

The production of leather stamps involves a series of well-coordinated manufacturing processes that ensure quality and precision. This section outlines the main stages of manufacturing, including material preparation, forming, assembly, and finishing, while also highlighting key techniques used in the industry.

How Is Material Prepared for Leather Stamp Production?

The first step in the manufacturing process is the preparation of materials. Typically, high-quality brass and steel are the primary materials used for creating custom leather stamps and cutting dies. The selection of these materials is crucial, as they directly impact the durability and performance of the stamps.

-

Material Sourcing: Suppliers must ensure that materials meet specific standards, such as corrosion resistance and tensile strength, to withstand repeated use.

-

Cutting and Shaping: Once the materials are sourced, they are cut into the required shapes and sizes. This often involves advanced techniques like CNC (Computer Numerical Control) machining, which allows for precision cutting and shaping of the material into the desired form.

-

Surface Preparation: After cutting, the surfaces of the materials are treated to enhance their adherence properties and ensure a smooth finish. This step may involve grinding or polishing to remove any burrs or imperfections.

What Techniques Are Used in the Forming Stage of Leather Stamps?

The forming stage is where the actual design of the stamp is created. This stage can involve various techniques, including:

-

CNC Milling: This is a critical technique used to engrave detailed designs onto the stamp. CNC milling machines can create intricate patterns and logos, ensuring that the final product meets the specific requirements of the buyer.

-

Die Casting: For some designs, especially those requiring high volume production, die casting may be employed. This method allows for the rapid creation of complex shapes, ensuring uniformity across batches.

-

Heat Treatment: After forming, the stamps may undergo heat treatment to improve their hardness and durability. This process is crucial for ensuring that the stamps can withstand the pressures of stamping leather over extended periods.

What Does the Assembly Process Involve for Leather Stamps?

After the forming stage, the stamps are assembled. This stage is essential for ensuring that all components fit together correctly and function as intended.

-

Component Integration: For stamps that require multiple parts, such as handles or interchangeable components, careful assembly is necessary. This may involve the use of adhesives or screws to secure parts together.

-

Alignment Checks: Accurate alignment is critical, especially for stamps intended for use with cutting dies. Manufacturers often use jigs or fixtures to ensure that all components are correctly aligned before final assembly.

How Is the Finishing Process Conducted for Leather Stamps?

Finishing is the final stage of manufacturing, where the stamps are prepared for delivery to buyers. This stage includes:

-

Surface Finishing: This may involve additional polishing or coating to enhance the aesthetic appeal and functionality of the stamps. A smooth finish not only looks professional but also helps in creating clear impressions on leather.

-

Quality Control Inspections: Before shipping, each stamp undergoes a final quality control inspection to ensure it meets the company’s standards and the specifications of the client.

What Quality Assurance Measures Are Implemented in Leather Stamp Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that the final products meet both international and industry-specific standards.

Illustrative image related to leather stamp maker

Which International Standards Should Buyers Look For?

For B2B buyers, understanding quality standards is essential. Some relevant international standards include:

-

ISO 9001: This standard outlines criteria for a quality management system. Adherence to ISO 9001 ensures that the manufacturer consistently meets customer and regulatory requirements, thus enhancing customer satisfaction.

-

CE Marking: Particularly relevant for suppliers in Europe, CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of work and ensure that the production is on track.

-

Final Quality Control (FQC): The final inspection occurs before shipping. This step involves checking the finished products against customer specifications and quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some actionable steps:

-

Request Documentation: Buyers should ask suppliers for quality assurance documentation, including ISO certification and internal quality control reports.

-

Conduct Audits: Buyers can perform audits of the manufacturing facilities to evaluate the quality management systems in place. This can also help in understanding the manufacturing processes firsthand.

-

Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of the supplier’s quality control processes and the condition of the products before shipment.

-

References and Reviews: Checking references and reviews from previous clients can provide insights into the supplier’s reliability and quality of products.

What Are the Nuances of Quality Control for International Buyers?

International buyers must be aware of specific nuances in quality control that may vary by region. For instance:

-

Compliance with Local Regulations: Different countries may have specific regulations regarding materials used in manufacturing. Buyers should ensure that suppliers are compliant with these regulations.

-

Cultural Differences in Quality Perception: What is considered acceptable quality may vary across cultures. Understanding these differences can help buyers set realistic expectations and improve communication with suppliers.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing leather stamps, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather stamp maker’

مقدمة

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure leather stamp-making services or products. By following these steps, you can ensure that you select a reliable supplier who meets your specific needs, whether you are a small artisan shop or a large-scale manufacturer.

Step 1: Define Your Technical Specifications

Clearly articulating your requirements is crucial before approaching suppliers. This includes detailing the type of leather stamps you need, such as custom designs, sizes, and materials (e.g., brass or steel). Having a well-defined specification helps suppliers provide accurate quotes and ensures that the final product meets your quality standards.

Step 2: Research Potential Suppliers

Invest time in researching various suppliers in the leather stamp industry. Look for companies that specialize in custom stamps and have a solid reputation for quality and reliability. Utilize online resources, industry directories, and customer reviews to create a shortlist of potential candidates.

Step 3: Evaluate Supplier Capabilities

Assess the technical capabilities of each supplier on your shortlist. Confirm whether they can meet your specific needs, such as precision CNC milling for custom stamps or the ability to produce cutting dies. Ask for samples of their work to evaluate the quality and craftsmanship before making a commitment.

Step 4: Verify Supplier Certifications and Compliance

It’s essential to check if the suppliers adhere to industry standards and certifications. Certifications can indicate a commitment to quality and sustainability, which is increasingly important in global sourcing. Look for suppliers that comply with international regulations, especially if you are sourcing from regions with stringent quality controls.

Step 5: Request Quotes and Compare Pricing

Once you have narrowed down your list, request detailed quotes from each supplier. Ensure that the quotes include all costs, such as shipping and any additional fees. Comparing pricing helps you assess the value offered by each supplier, but remember that the cheapest option may not always be the best in terms of quality and service.

Step 6: Assess Customer Support and Communication

Effective communication is key to a successful partnership. Evaluate how responsive and helpful the suppliers are during your inquiries. A supplier that provides prompt and informative responses is more likely to offer excellent support throughout your procurement process, which is crucial for resolving any issues that may arise.

Illustrative image related to leather stamp maker

Step 7: Confirm Delivery Times and Terms

Before finalizing your order, clarify delivery timelines and payment terms. Understanding the expected lead time for production and shipping is vital for planning your own operations. Ensure that the supplier can meet your deadlines, especially if you have tight schedules for launching products or fulfilling customer orders.

By following this step-by-step checklist, you can confidently navigate the procurement process for leather stamp makers, ensuring that you select a supplier that aligns with your business needs and quality expectations.

Comprehensive Cost and Pricing Analysis for leather stamp maker Sourcing

When sourcing leather stamps, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. This section provides an in-depth analysis of cost components, pricing influencers, and practical buyer tips to optimize your procurement process.

What Are the Key Cost Components in Leather Stamp Manufacturing?

-

Materials: The primary materials for leather stamps include solid brass for stamps and high-quality steel for cutting dies. Prices can fluctuate based on market demand and material quality. Buyers should consider sourcing materials that balance cost with performance to ensure durability and effectiveness.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as some parts of Africa and South America, the overall production cost can be reduced. However, skilled labor is essential for precision machining and quality assurance, which may be higher in regions like Europe.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead, impacting the final price positively.

-

Tooling: Custom tooling for specific designs adds to initial costs but is essential for producing unique stamps. Buyers should weigh the cost of tooling against the anticipated volume to determine if it’s a worthwhile investment.

-

Quality Control (QC): Implementing stringent QC processes ensures that the final products meet the required specifications. While this adds to the cost, it is vital for maintaining product quality, especially in high-stakes markets.

-

Logistics: Shipping costs can vary based on the supplier’s location and chosen Incoterms. Buyers must account for these costs in their total expenditure, especially when sourcing from international suppliers.

-

Margin: Suppliers will typically add a profit margin on top of their costs. This margin can vary based on the supplier’s pricing strategy and market competition.

How Do Pricing Influencers Affect Leather Stamp Costs?

-

Volume/MOQ: Larger orders often qualify for discounts, making it beneficial for buyers to consolidate orders. Minimum Order Quantities (MOQs) can also affect pricing, as lower quantities may not yield the same cost benefits.

-

Specifications and Customization: Custom designs and specifications can significantly impact pricing. Complex designs may incur higher tooling and labor costs, while standard products are generally more cost-effective.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO) can increase costs but may be necessary for specific applications, particularly in regulated markets.

-

Supplier Factors: Supplier reputation, production capacity, and geographic location play critical roles in pricing. Established suppliers with a track record of quality may command higher prices but offer better reliability.

-

Incoterms: Understanding the terms of shipping and delivery is vital. Incoterms dictate who is responsible for shipping costs, insurance, and tariffs, which can significantly influence the total cost of ownership.

What Are the Best Negotiation and Cost-Efficiency Tips for Buyers?

-

Negotiate Based on Total Cost of Ownership: Rather than focusing solely on the initial price, consider the total cost of ownership, including maintenance, durability, and potential reorders.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and take advantage of bulk pricing.

-

Seek Multiple Quotes: Gathering quotes from several suppliers can provide leverage in negotiations and help identify the most competitive pricing.

-

Consider Local Suppliers: For buyers in Africa or South America, sourcing from local suppliers can reduce logistics costs and lead times.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations and potential import tariffs when budgeting for international purchases.

Disclaimer

The prices discussed are indicative and may vary based on specific supplier agreements, market conditions, and buyer requirements. It is advisable for buyers to conduct thorough market research and engage in direct negotiations with suppliers to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing leather stamp maker With Other Solutions

Exploring Alternative Solutions for Leather Stamping Needs

In the world of leather crafting, the choice of stamping solutions can significantly impact the quality and efficiency of production. While the Leather Stamp Maker offers a robust and user-friendly option for creating custom stamps, it’s essential to evaluate other viable alternatives. This analysis will compare Leather Stamp Maker with two alternative solutions: traditional hand stamping and laser engraving.

| Comparison Aspect | Leather Stamp Maker | Traditional Hand Stamping | Laser Engraving |

|---|---|---|---|

| Performance | High precision and consistency | Variable quality; depends on skill | Extremely high precision and detail |

| Cost | Moderate initial investment | Low initial cost, but labor-intensive | Higher upfront cost for equipment |

| Ease of Implementation | Simple online ordering and quick shipping | Requires skilled labor and practice | Requires training and setup time |

| Maintenance | Minimal; durable materials | Occasional tool replacement | Regular maintenance of laser equipment |

| Best Use Case | Mass production of custom designs | Small-scale, artisanal work | High-detail projects and complex designs |

What Are the Advantages and Disadvantages of Traditional Hand Stamping?

Traditional hand stamping involves manually using metal stamps to imprint designs onto leather. This method is often favored by artisans for its tactile nature and ability to create unique, one-off pieces. However, the performance can vary widely depending on the skill level of the craftsman. While the initial costs are low—primarily involving the purchase of stamps—this method is labor-intensive and time-consuming. Additionally, achieving consistent quality can be challenging, particularly in mass production scenarios.

How Does Laser Engraving Compare to Leather Stamp Maker?

Laser engraving is a modern technique that uses laser technology to etch designs into leather. This method offers unparalleled precision and the ability to create intricate designs that may be difficult or impossible to achieve with traditional stamping. However, the initial investment for laser engraving equipment is significantly higher than that of the Leather Stamp Maker. Moreover, it often requires specialized training to operate the machinery effectively, which can add to implementation time. Despite these drawbacks, laser engraving is ideal for businesses looking to produce detailed work at scale.

Conclusion: How to Choose the Right Leather Stamping Solution for Your Needs?

When selecting a leather stamping solution, consider your specific business requirements, budget constraints, and production scale. The Leather Stamp Maker stands out for its ease of use and efficient turnaround, making it a strong contender for businesses focused on custom designs at a moderate scale. Traditional hand stamping may be suitable for artisans emphasizing craftsmanship and individuality, whereas laser engraving is best for those prioritizing precision and complexity in design. By carefully assessing these factors, B2B buyers can make informed decisions that align with their operational goals and enhance their product offerings.

Essential Technical Properties and Trade Terminology for leather stamp maker

What Are the Key Technical Properties of Leather Stamps?

When sourcing leather stamps, it’s crucial to understand certain technical specifications that can greatly influence the quality and functionality of the final product. Here are some key properties:

1. Material Grade

Leather stamps are typically made from high-quality materials such as brass or steel. Brass is favored for its corrosion resistance and durability, making it ideal for custom stamping. Steel, particularly in cutting dies, offers strength and longevity, crucial for repeated use. Understanding material grades helps B2B buyers assess the expected lifespan and performance of the stamps.

2. Tolerance

Tolerance refers to the allowable deviation in the dimensions of the stamp or die. In leather stamping, maintaining tight tolerances is essential for achieving crisp, accurate impressions. A tolerance of ±0.01 inches is often standard, ensuring that the stamp performs reliably across various applications. For B2B buyers, understanding tolerances can guide decisions in selecting suppliers who can meet specific quality requirements.

3. Thickness

The thickness of a stamp can range from 1/4 inch to 1 inch or more. Thicker stamps tend to be more robust and provide deeper impressions, which is beneficial for certain applications like branding. Buyers should consider the intended use of the stamp when evaluating thickness, as it can impact both the aesthetic and functional qualities of the stamped leather.

4. Customization Capabilities

Customization is a significant aspect of leather stamping. The ability to create bespoke designs, including logos or unique patterns, can set a business apart in a competitive market. B2B buyers should inquire about a manufacturer’s capacity for customization, including the complexity of designs and the available turnaround times.

5. Compatibility with Equipment

Stamps must be compatible with various stamping machines, including mechanical and hydraulic presses. Understanding the compatibility of the stamp with existing machinery is crucial for efficient production processes. This consideration can help B2B buyers avoid costly equipment upgrades or modifications.

What Are Common Trade Terms in the Leather Stamping Industry?

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

In the leather stamping context, OEM refers to a manufacturer that produces stamps or dies that are sold by another company under its own brand. Understanding OEM relationships can help buyers identify potential partners for sourcing high-quality products without the need for extensive in-house manufacturing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products that a supplier is willing to sell. For leather stamps, MOQs can vary significantly depending on the manufacturer. B2B buyers should be aware of MOQs to manage inventory costs and ensure they are ordering quantities that align with their production needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers often use RFQs to gather information on pricing, lead times, and terms of service. This process allows for informed decision-making when selecting suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Terms such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight) clarify who bears costs and risks at various stages of the shipping process. Understanding these terms is essential for B2B transactions, especially when dealing with international suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. In the leather stamping industry, lead times can vary based on customization and production schedules. B2B buyers should factor in lead times when planning their production cycles to avoid disruptions.

Illustrative image related to leather stamp maker

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing leather stamps, ensuring they align with their business needs and operational capabilities.

Navigating Market Dynamics and Sourcing Trends in the leather stamp maker Sector

What Are the Key Trends Shaping the Leather Stamp Maker Market?

The leather stamp maker sector is experiencing significant growth, driven by the rising demand for personalized and custom leather goods across various industries. Global drivers such as the expansion of e-commerce, increased consumer interest in handmade and artisanal products, and a resurgence of traditional craftsmanship are shaping market dynamics. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on unique branding solutions, making custom leather stamps an essential tool for businesses ranging from fashion to home décor.

Emerging technologies such as CNC milling and laser engraving are enhancing the precision and efficiency of stamp production. These advancements allow suppliers to offer rapid turnaround times for custom orders, appealing to businesses that require quick and reliable service. Additionally, the integration of digital platforms for order placement and design proofs streamlines the sourcing process, enabling buyers to interact with manufacturers directly and reduce lead times.

Illustrative image related to leather stamp maker

Another trend is the growing preference for high-quality materials, particularly solid brass and steel, known for their durability and performance. As B2B buyers become more quality-conscious, manufacturers must ensure that their offerings not only meet but exceed industry standards. This trend is particularly evident in markets like Germany, where precision engineering and product reliability are paramount.

How Is Sustainability Influencing the Leather Stamp Maker Sector?

Sustainability and ethical sourcing are becoming increasingly vital considerations for B2B buyers in the leather stamp maker sector. The environmental impact of leather production, particularly concerning deforestation and water usage, has raised awareness among consumers and businesses alike. Consequently, buyers are seeking suppliers who prioritize sustainable practices, such as using eco-friendly materials and processes in their manufacturing.

Certifications like the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining traction as indicators of responsible sourcing. B2B buyers are encouraged to look for manufacturers that comply with these certifications, ensuring that their products are produced with minimal environmental impact and adhere to ethical labor practices.

Moreover, the demand for ‘green’ materials, such as vegetable-tanned leather and biodegradable alternatives, is on the rise. This shift not only aligns with consumer preferences but also enhances brand reputation in a competitive marketplace. By adopting sustainable practices, leather stamp makers can position themselves as leaders in responsible manufacturing, appealing to conscientious buyers.

What Is the Historical Context of the Leather Stamp Maker Industry?

The leather stamp maker industry has evolved significantly over the past century. Initially, leather stamping was a labor-intensive process, relying on hand-carved stamps and manual techniques. As the leather goods market expanded, the need for efficiency and precision led to the introduction of mechanized processes in the mid-20th century.

The advent of CNC milling technology in the late 20th century revolutionized the industry, allowing for greater accuracy and customization. This technological advancement not only improved production speeds but also enabled artisans and businesses to create intricate designs that were previously unattainable.

Today, the sector continues to innovate, blending traditional craftsmanship with modern technology. This evolution reflects broader shifts in consumer behavior, where personalization and quality are increasingly prioritized. For B2B buyers, understanding this historical context provides valuable insights into the capabilities and potential of current suppliers in the leather stamp maker market.

Frequently Asked Questions (FAQs) for B2B Buyers of leather stamp maker

-

How do I choose the right leather stamp maker for my business needs?

When selecting a leather stamp maker, consider their experience, product range, and customization options. Look for suppliers who offer high-quality materials, such as solid brass or steel, and can provide samples or proofs before production. Additionally, evaluate their turnaround time and customer service responsiveness. Reading reviews from other B2B buyers can also provide insights into their reliability and product quality. Ensure they can accommodate your specific requirements, such as unique designs or sizes, to meet your branding needs effectively. -

What customization options are available for leather stamps?

Most leather stamp makers offer extensive customization options, including the ability to create personalized logos, shapes, or text. You can typically request specific sizes, thicknesses, and designs to align with your branding or product requirements. Some suppliers also provide virtual proofs before production, allowing you to visualize the final product. It’s essential to communicate your vision clearly and inquire about any limitations on customization to ensure the final product meets your expectations. -

What are the minimum order quantities (MOQs) for leather stamps?

Minimum order quantities can vary widely among leather stamp makers. Some suppliers may have no MOQ for custom stamps, while others might require a minimum order of several units. When sourcing, clarify the MOQ upfront to avoid any misunderstandings. Keep in mind that ordering larger quantities often leads to cost savings per unit, which can be beneficial for businesses planning to scale production or offer a variety of products. -

What payment terms should I expect when ordering leather stamps internationally?

Payment terms will vary by supplier and may include options such as upfront payment, partial payment before production, or payment upon delivery. Many suppliers accept various payment methods, including bank transfers, credit cards, or PayPal. It’s crucial to discuss and agree upon the payment terms before placing an order to ensure a smooth transaction. Additionally, inquire about any potential customs duties or taxes that may apply to international shipments, as these can affect your total costs. -

How can I ensure quality assurance (QA) for my leather stamps?

To ensure quality assurance, work with suppliers that have a proven track record of delivering high-quality products. Request samples before placing a large order to evaluate the craftsmanship and material quality. Many reputable manufacturers will also offer guarantees or warranties on their products. Establishing clear specifications and communication channels can help address any concerns during production. It may also be beneficial to visit the manufacturer’s facility if possible, or to work with third-party quality control services for larger orders. -

What shipping options are available for international orders of leather stamps?

Shipping options for international orders can include standard air freight, express courier services, or sea freight for larger shipments. Discuss with your supplier about the most cost-effective and timely shipping methods for your location. Ensure that the supplier provides tracking information for your shipment. Additionally, clarify who will be responsible for customs clearance and any associated fees to prevent delays upon arrival. -

How do I handle issues or disputes with a leather stamp supplier?

If issues arise, such as delays or product quality concerns, maintain open communication with your supplier. Document all correspondence and clearly outline your concerns. Most reputable suppliers will work with you to resolve issues amicably. If necessary, refer to your contract or purchase agreement for guidance on dispute resolution procedures. Consider using third-party mediation if direct communication does not yield satisfactory results. -

What are the trends in leather stamping technology I should be aware of?

Staying updated on trends in leather stamping technology can enhance your product offerings. Innovations such as CNC milling for precision stamping, digital printing for complex designs, and eco-friendly materials are gaining traction. Additionally, automation and smart manufacturing processes can improve efficiency and reduce lead times. Researching these trends can provide insights into how you can differentiate your products and meet evolving customer preferences in the competitive leather goods market.

Top 7 Leather Stamp Maker Manufacturers & Suppliers List

1. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

مقدمة: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets, and more. Custom stamps are CNC milled from solid brass, available up to 1″ thickness and custom size. Can be used with branding irons and standard presses. Custom leather cutting dies made from solid steel, compatible with mechanical, hydr…

2. Infinity Stamps – Leather Stamps

Domain: infinitystamps.com

Registered: 2001 (24 years)

مقدمة: Leather Stamps – Handheld and plate stamps for leather, including pin marking devices and roll dies. Made in the USA by a family-owned business with over 25 years of experience. Contact available via phone or online form.

3. LeatherstampTools – Custom Leather Stamps

Domain: reddit.com

Registered: 2005 (20 years)

مقدمة: Custom leather stamps, good price point, quality stamp, options include Leatherstampstools on Etsy, Springfield Leather for custom designs, leatherstampmaker in the US with free quotes and proof, TyraCraftTools on Etsy with a $55 price for a 2.5 cm x 5 cm stamp.

4. Gearheart Industry – Custom Leather Stamp

Domain: gearheartindustry.com

Registered: 2013 (12 years)

مقدمة: {“product_name”: “Custom Leather Stamp”, “price”: “$119.00”, “dimensions”: [“1” x “1””, “1” x “1.5””, “1.5” x “1.5””], “production_time”: [“Standard (5 Business Days)”, “RUSH (1 Business Day)”], “file_types”: [“bmp”, “gif”, “jpg”, “jpeg”, “jpe”, “jif”, “jfif”, “jfi”, “png”, “wbmp”, “xbm”, “tiff”, “ai”, “eps”, “pdf”], “max_file_size”: “524288KB”, “features”: {“custom_made”: “per your specifications…

5. Steel Stamps Inc. – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

مقدمة: Custom Leather Stamps available at Steel Stamps Inc. include various designs such as Sheridan flowers/leaves, state stamps, and jewelry design stamps. The collection features Pro Series designs, Tried & True series, and Avant-Garde series. Additionally, there are specialized stamps like Do Not Duplicate and Master stamps for locksmiths. All products are made in the U.S.A.

6. Buckeye Engraving – Custom Leather Stamps

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

مقدمة: Custom Leather Stamps, Steel Leather Hand Stamps, USA Made, Custom Steel Hand Stamps, Custom Knife Stamps, Custom Blacksmith Stamps, Glass Stamps, Jewelry Stamps, Leather Stamps, Wood Stamps, Pipe Stamps, Branding Irons, Custom Products, Custom Leather Stamps and Dies, Aluminum, Steel, Brass options, High detail stamps, Hand-finished, Heavy-duty removable steel handle, Custom engraved stamp face, …

7. Infinimark – Handheld Leather Maker Stamps

Domain: infinimark.com

Registered: 2016 (9 years)

مقدمة: {“product_name”: “Handheld Leather Maker Stamps”, “price”: “$216.00”, “features”: [“Custom engraved per specifications”, “Precision made for high-detail capability”, “Made in-house in the U.S.A.”, “Stamp face raised 3/32″ (2.3 mm) for clear impressions”, “Made from quality tool steel, hardened for durability”], “weight”: “varies from 0.21 – 3.38 lbs”, “recommended_use”: [“Standard 16 oz. Ball-Peen…

Strategic Sourcing Conclusion and Outlook for leather stamp maker

In today’s competitive landscape, the value of strategic sourcing for leather stamp makers cannot be overstated. By prioritizing quality, customization, and swift turnaround times, businesses can significantly enhance their branding efforts and overall product quality. Leveraging suppliers that offer a seamless ordering process, as well as responsive customer service, is crucial for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe.

Investing in high-quality custom brass stamps and cutting dies not only elevates a brand’s identity but also streamlines production processes, resulting in cost savings and increased efficiency. The ability to create unique designs tailored to specific markets allows businesses to differentiate themselves and meet diverse consumer needs.

Looking ahead, the demand for innovative leather stamping solutions is expected to grow. B2B buyers are encouraged to explore partnerships with reliable suppliers who can provide not just products, but also valuable insights and support throughout the sourcing journey. By embracing these opportunities, businesses can position themselves for success in an evolving marketplace, ensuring they remain at the forefront of the leather goods industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.